A kind of low-voltage soft state corrosion anode aluminum foil and its preparation method and application

A technology of anode aluminum foil and soft state, which is applied in the field of low-pressure soft-state corrosion anode aluminum foil and its preparation, can solve the problems of poor passivation effect of intermediate treatment, low specific volume of low-voltage soft-state corrosion anode aluminum foil, etc., to improve passivation ability, The effect of promoting growth and increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

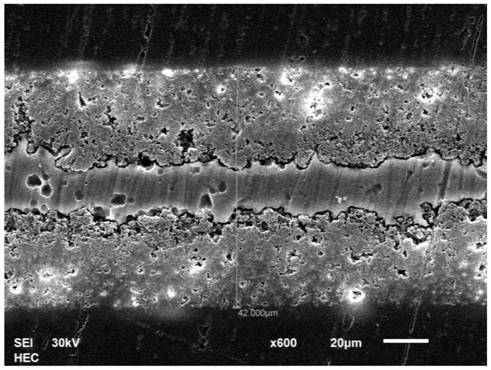

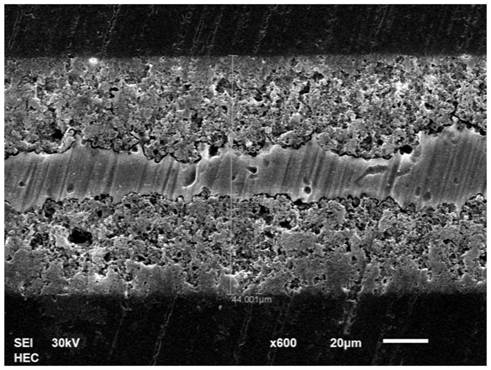

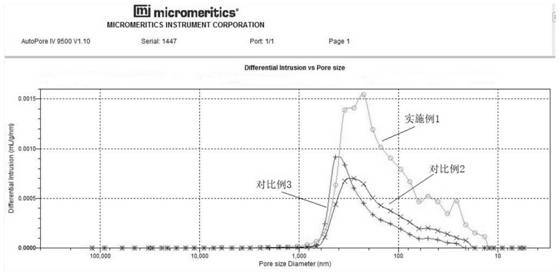

Image

Examples

Embodiment 1

[0061] A low-pressure soft-state corrosion method for anode aluminum foil, comprising the steps of:

[0062] S1. Prepare a 105 μm low-pressure soft anodic electronic aluminum foil (light foil) with a sample area of 5.5cm×13cm, and perform degreasing treatment in phosphoric acid with a temperature of 70°C and a concentration of 1.5wt% for 1min;

[0063] S2. Electrochemical corrosion: put the low-voltage soft anode electronic aluminum foil in S1 in a mixed solution of 10wt% hydrochloric acid and 0.02wt% sulfuric acid, and use a current density of 0.25A / cm 2 The non-sinusoidal alternating current is used for galvanic corrosion for 60s, and after the corrosion is completed, it is washed with water;

[0064] S3 sintering treatment: put the aluminum foil obtained in S2 in a sintering furnace and sinter at 300°C for 0.5 minutes;

[0065] S4. Intermediate treatment: place the aluminum foil obtained in S3 in an alkaline salt solution passivation solution containing phosphorus and ni...

Embodiment 2

[0070] A low-pressure soft-state corrosion method for anode aluminum foil, comprising the steps of:

[0071] S1. Prepare a 105 μm low-pressure soft anodic electronic aluminum foil (light foil) with a sample area of 5.5cm×13cm, and perform degreasing treatment in phosphoric acid with a temperature of 70°C and a concentration of 1.5wt% for 1min;

[0072] S2. Electrochemical corrosion: put the low-voltage soft anode electronic aluminum foil in S1 in a mixed solution of 3wt% hydrochloric acid and 2wt% sulfuric acid, and use a current density of 0.05A / cm 2 The non-sinusoidal alternating current is used for galvanic corrosion for 60s, and after the corrosion is completed, it is washed with water;

[0073] S3 sintering treatment: put the aluminum foil obtained in S2 in a sintering furnace and sinter at 250°C for 0.5 minutes;

[0074] S4. Intermediate treatment: place the aluminum foil obtained in S3 in an alkaline salt solution passivation solution containing phosphorus and nitrog...

Embodiment 3

[0079] A low-pressure soft-state corrosion method for anode aluminum foil, comprising the steps of:

[0080] S1. Prepare a 105 μm low-voltage soft anodic electronic aluminum foil (light foil) with a sample area of 5.5cm×13cm, and perform degreasing treatment in phosphoric acid with a temperature of 70°C and a concentration of 1.5wt% for 1min;

[0081] S2. Electrochemical corrosion: put the low-voltage soft anode electronic aluminum foil in S1 in a mixed solution of 15wt% hydrochloric acid and 0.001wt% sulfuric acid, and use a current density of 0.3A / cm 2 The non-sinusoidal alternating current is used for galvanic corrosion for 60s, and after the corrosion is completed, it is washed with water;

[0082] S3 sintering treatment: put the aluminum foil obtained in S2 in a sintering furnace and sinter at 350°C for 0.5 minutes;

[0083] S4. Intermediate treatment: place the aluminum foil obtained in S3 in an alkaline salt solution passivation solution containing phosphorus and nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com