Turf module applied to high and steep slope and planting method of turf module

A technology for high and steep slopes and turf, which is applied to the turf module of high and steep slopes and its planting field, and can solve the problems of difficult laying and growth of turf.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

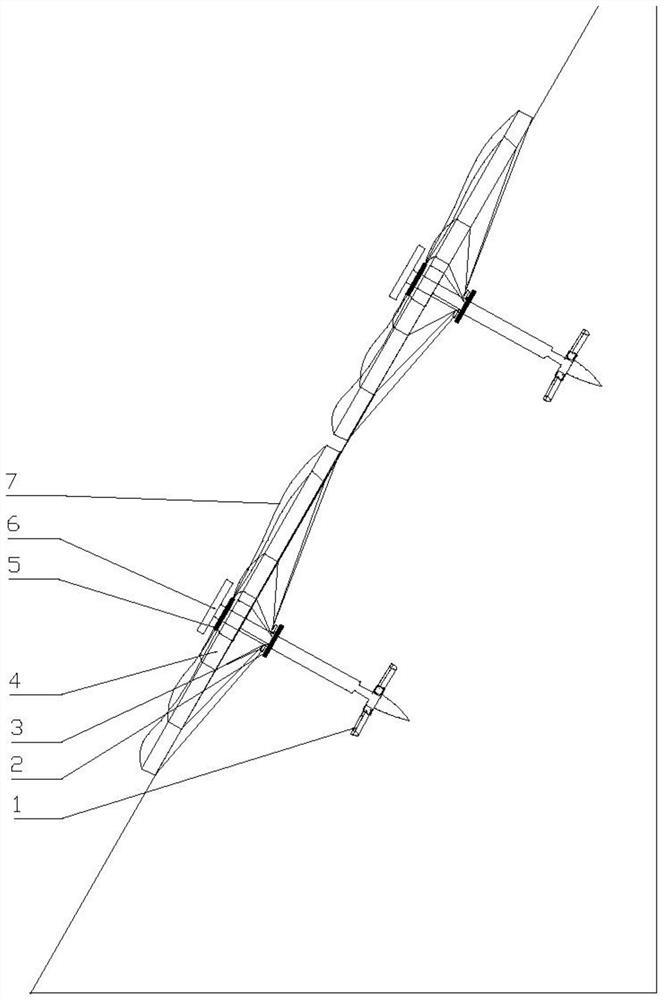

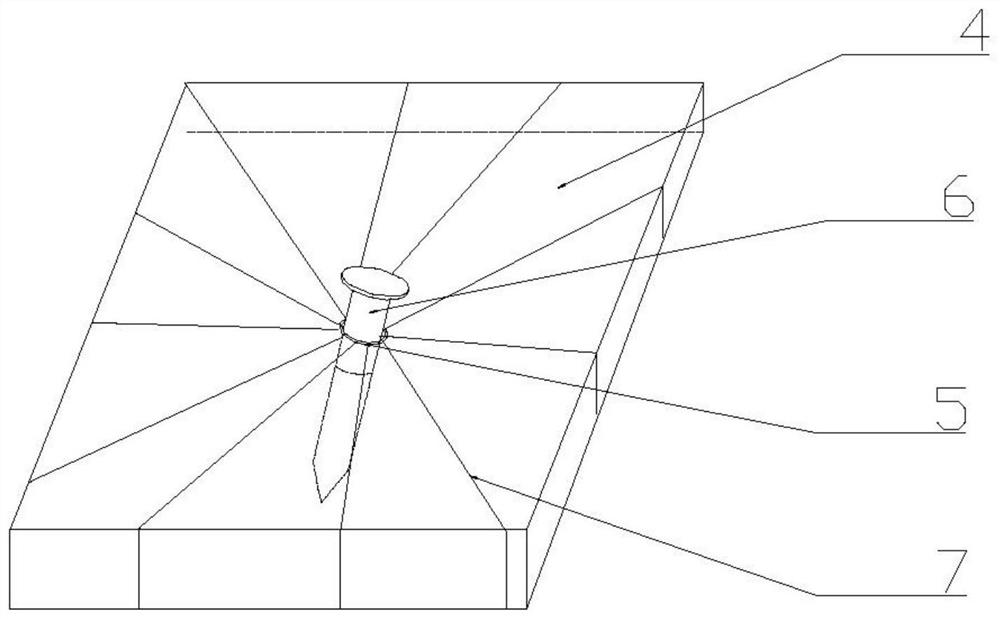

[0018] A turf module applied to high and steep slopes and a planting method thereof, the turf module is composed of a matrix module and a turf layer, the turf module is fixed on the high and steep slope surface by ecological nails; the matrix module is composed of a matrix block (4) and a pre- It is composed of buried and fixed components, and the matrix block (4) is a hollow square matrix block formed by mixing and pressing coconut bran silk, fiber silk, coconut bran, perlite, water-retaining agent, binder, and magnetic powder according to a certain proportion. In parts by weight, 10-20% of coconut bran and fiber, 40-50% of coconut bran, 5-10% of perlite, 10-20% of water retention agent, 5-10% of binder, and 10-20% of magnetic powder. The pre-embedded fixing component is composed of a traction wire (7), an upper magnetic ring (5) and a lower magnetic ring (2), and both the upper magnetic ring (5) and the lower magnetic ring (2) are located in the hollow of the matrix block (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com