Device for producing ship superstructure wave-shaped enclosure bulkhead plate and method for pressing wave-shaped enclosure bulkhead plate

A technology of superstructure and siding, applied in the field of shipbuilding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

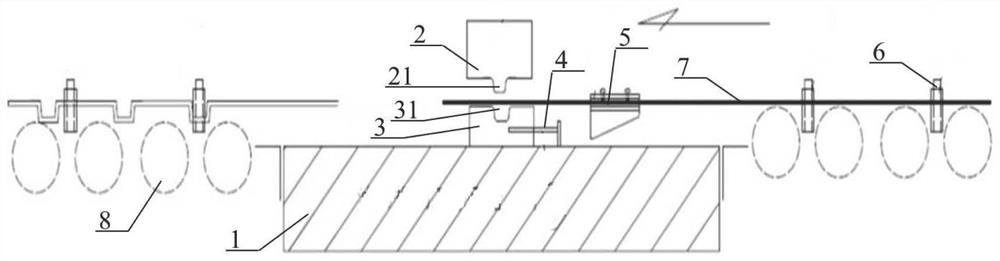

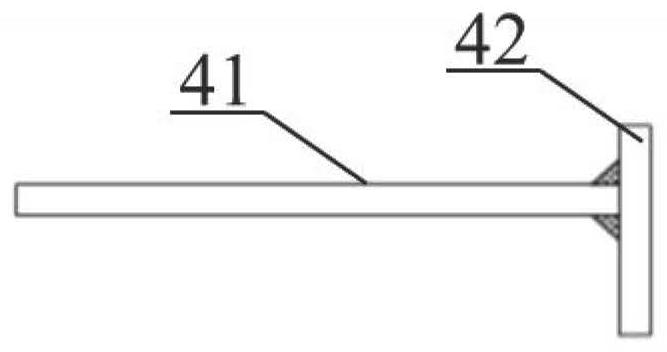

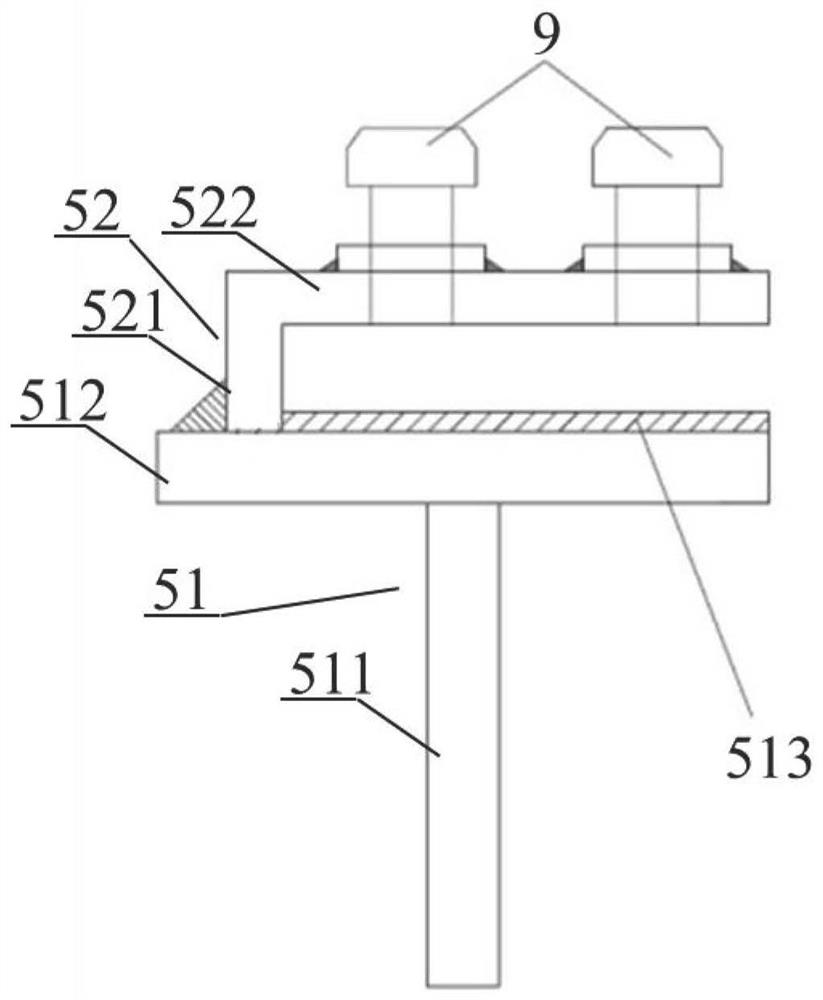

[0030] Such as Figure 1-Figure 3 As shown, a device for producing corrugated wall panels for ship superstructures, including a hydraulic press 1, a corrugated pressing upper die 2, a corrugated pressing lower die 3, a mold retaining tooling 4, and combined tooling 5 and 16 Roller limiting device 6, the waveform pressing lower mold 3 is fixed on the working platform of the hydraulic press 1, the waveform pressing upper mold 2 can move up and down and is arranged directly above the waveform pressing lower mold 3, the combination The tooling 5 is fixed on the steel plate 7 to be pressed, and the mold is fixed on the side wall of the corrugated pressing lower mold 3 near the side of the combined tooling 5 by the blocking tooling 4; a plurality of rollers 8, a plurality of rollers 8 are symmetrically arranged on the left and right sides outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com