Automatic assembly production method for stainless steel hasps

An automatic assembly and production method technology, which is applied in the field of mechanical parts assembly, can solve the problems of long pull ring length, equipment shutdown, and inability to install positioning pins, etc., so as to improve assembly efficiency and ensure production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

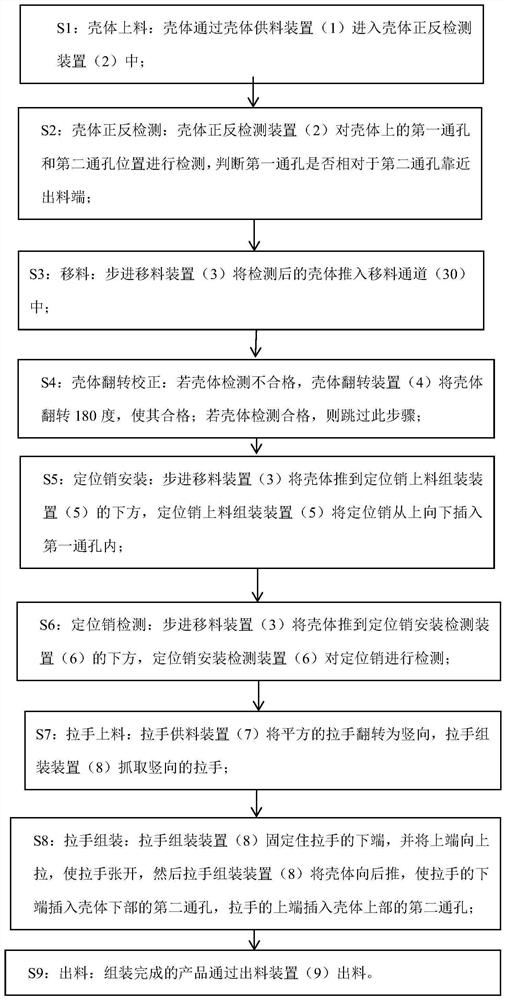

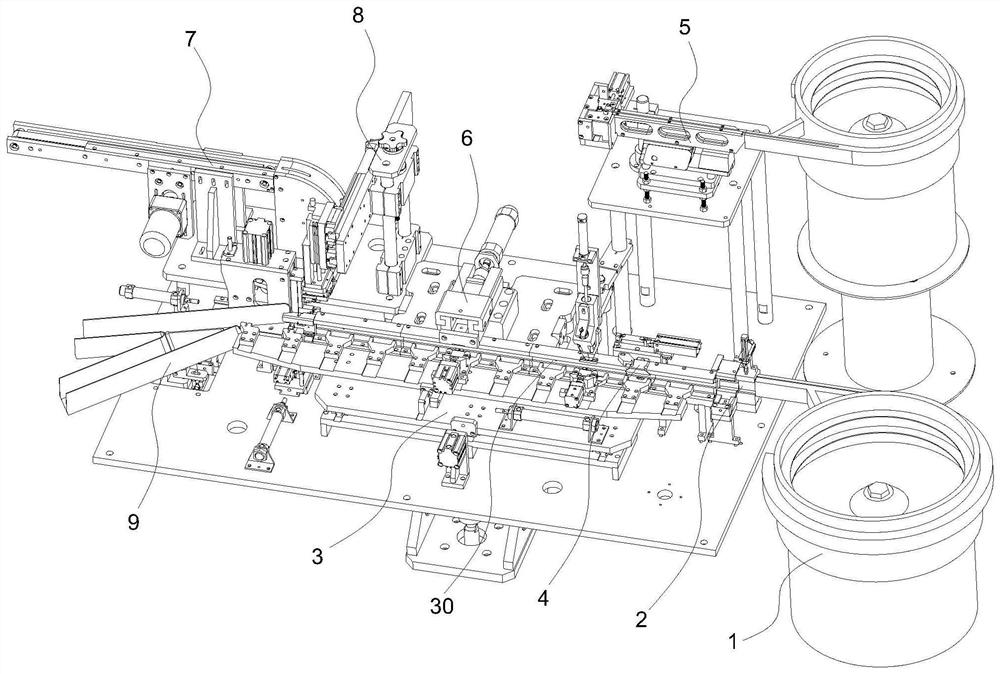

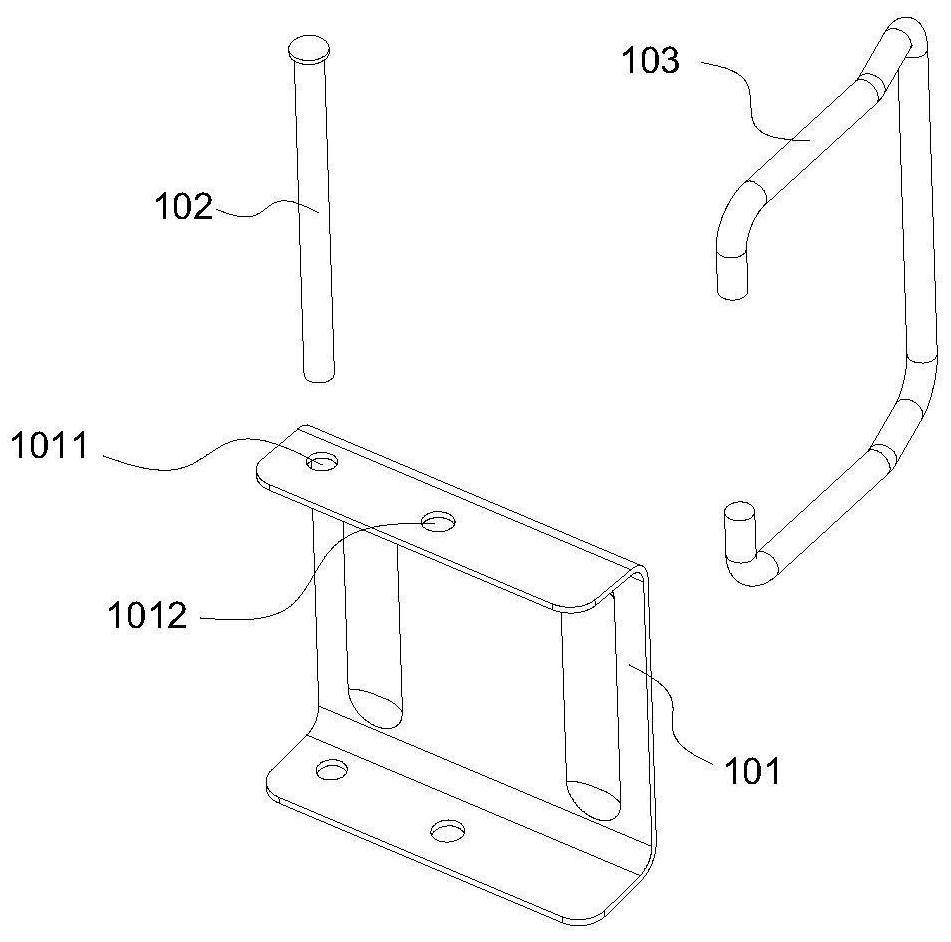

[0053] A kind of stainless steel buckle automatic assembly production method, the equipment that this method adopts such as figure 2 As shown, it includes the frame and the shell feeding device 1 installed on the frame, the positive and negative detection device 2 of the shell, the stepping material shifting device 3, the shell turning device 4, the positioning pin feeding assembly device 5, the positioning pin Pin installation detection device 6 , pull ring feeding device 7 , pull ring assembly device 8 and discharge device 9 . The shell feeding device 1 is arranged at one end of the frame, the output end of the shell feeding device 1 connects with the feeding end of the shell positive and negative detection device 2, and the discharge end of the shell positive and negative detection device 2 connects with the stepping shifter. Material device 3. The stepping material shifting device 3 is horizontally installed in the middle of the frame, and the stepping material moving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com