Production device and preparation method of basalt-reinforced polypropylene composite material

A composite material and production device technology, applied in the production device and its preparation field of basalt-reinforced polypropylene composite material, can solve the problems of uncontrollable, unfavorable use, poor molding effect, etc. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

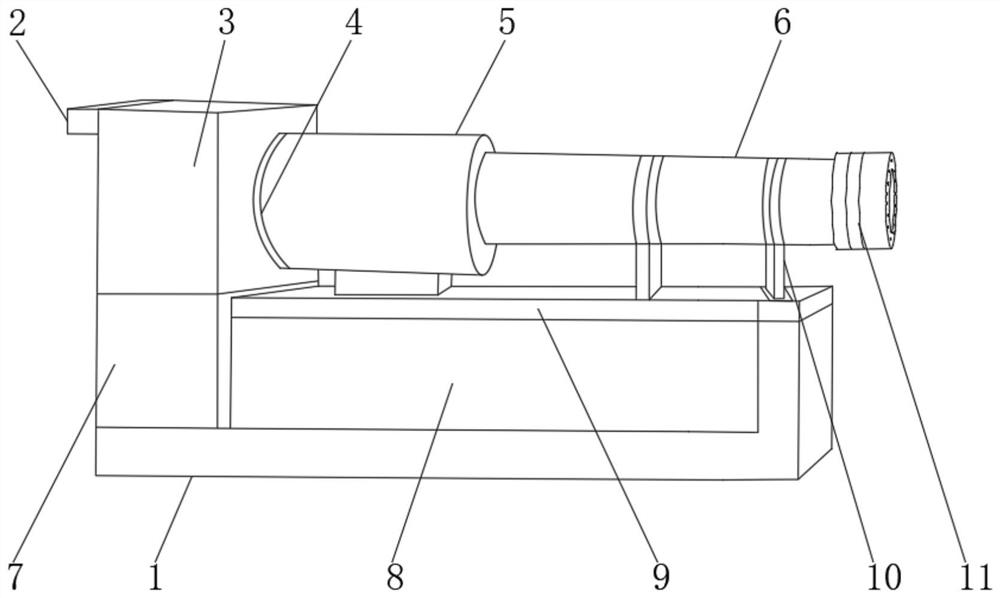

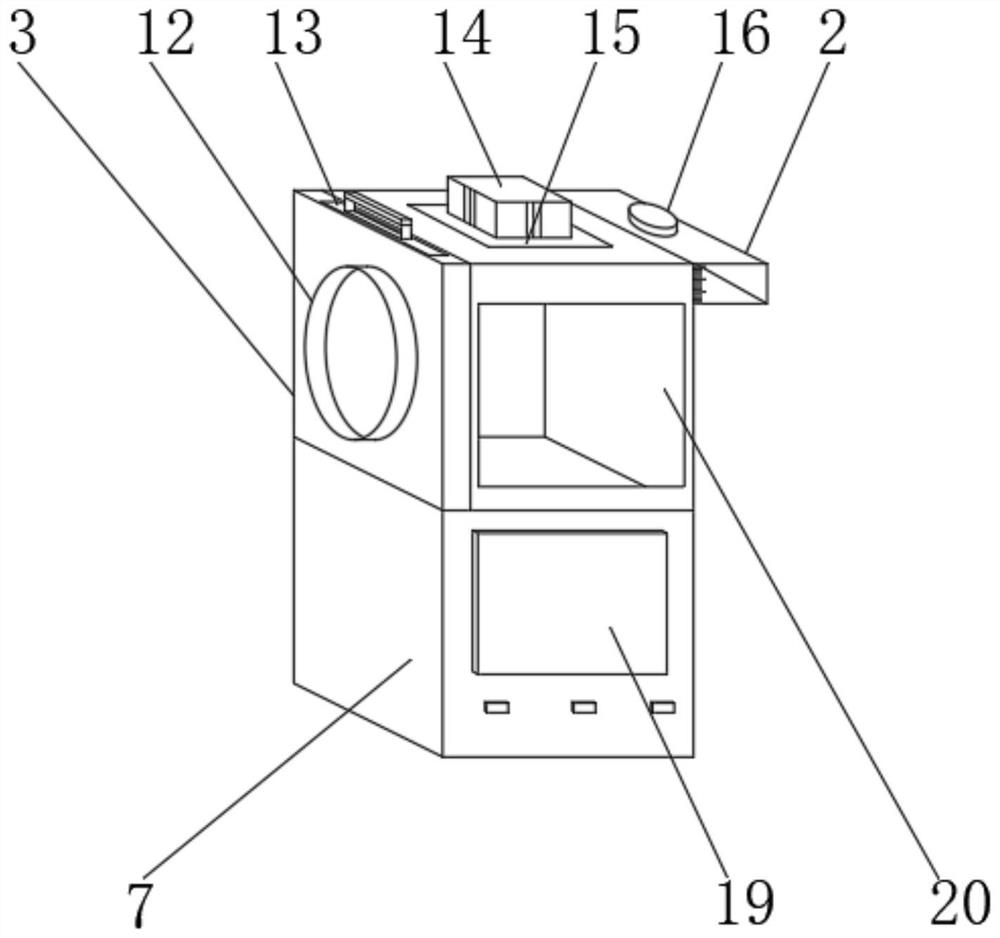

[0032] like Figure 1-3 As shown, a production device for basalt reinforced polypropylene composite material includes a device base 1, a heating control box 7 and a positioning seat 8 are installed on the upper end of the device base 1, and a heating blending box 3 is installed on the upper end of the heating control box 7, A feeding box 2 is installed on one side of the heating and blending box 3, a discharge port 12 is installed on the other side of the heating and blending box 3, and an installation clamp 4 is installed on the outer side of the discharge port 12, and the outer side of the installation clamp 4 is installed. The extruder base 5 is installed, and the control panel 19 is installed at the front end of the heating control box 7 .

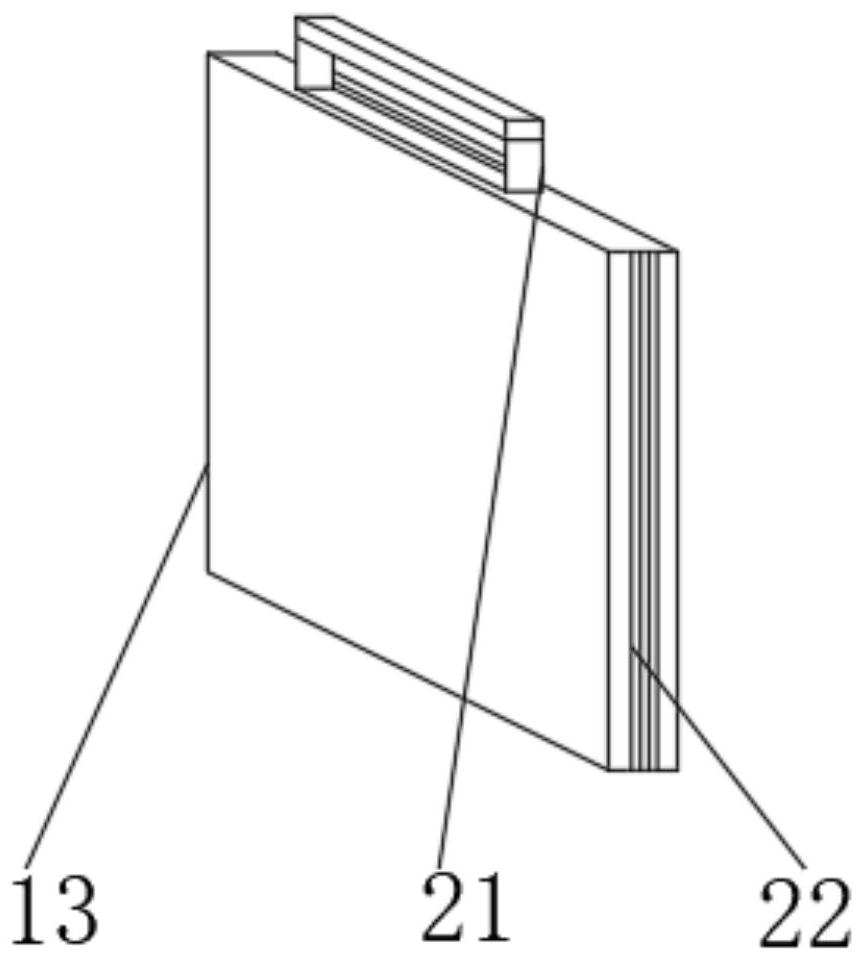

[0033] Further, a sealing valve plate 13 is installed on the inner side of the front end of the heating and blending box 3 , a handle 21 is installed on the upper end of the sealing valve plate 13 , sliding rails 22 are provided on bot...

Embodiment 2

[0041] On the basis of Example 1, as figure 1 , 2 , 4, a production device for basalt reinforced polypropylene composite material, including a device base 1, the upper end of the device base 1 is installed with a heating control box 7 and a positioning seat 8, and the upper end of the heating control box 7 is installed with a heating blending box 3. A feeding box 2 is installed on one side of the heating and blending box 3, a discharge port 12 is installed on the other side of the heating and blending box 3, and an installation clamp 4 is installed on the outside of the discharge port 12, and the installation clamp 4 The extruder base 5 is installed on the outer side of the heating control box 7 , and the control panel 19 is installed at the front end of the heating control box 7 .

[0042] Further, a positioning card plate 15 is installed on the upper end of the heating and blending box 3, the four corners of the positioning card plate 15 are installed with adjustment member...

Embodiment 3

[0050] On the basis of the second embodiment, as figure 1 , 2 , 5, a production device for basalt reinforced polypropylene composite material, including a device base 1, the upper end of the device base 1 is installed with a heating control box 7 and a positioning seat 8, and the upper end of the heating control box 7 is installed with a heating blending box 3. A feeding box 2 is installed on one side of the heating and blending box 3, a discharge port 12 is installed on the other side of the heating and blending box 3, and an installation clamp 4 is installed on the outside of the discharge port 12, and the installation clamp 4 The extruder base 5 is installed on the outer side of the heating control box 7 , and the control panel 19 is installed at the front end of the heating control box 7 .

[0051] Further, a valve 23 is installed on the inner side of the feed box 2, a discharge valve 25 is provided at the bottom of the feed box 2, a feed pipe 16 is installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com