Building plastic pipe bending equipment

A plastic pipe and construction technology, applied in the field of construction engineering, can solve the problems of high labor intensity and low bending efficiency of workers, and achieve the effect of reducing labor intensity and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

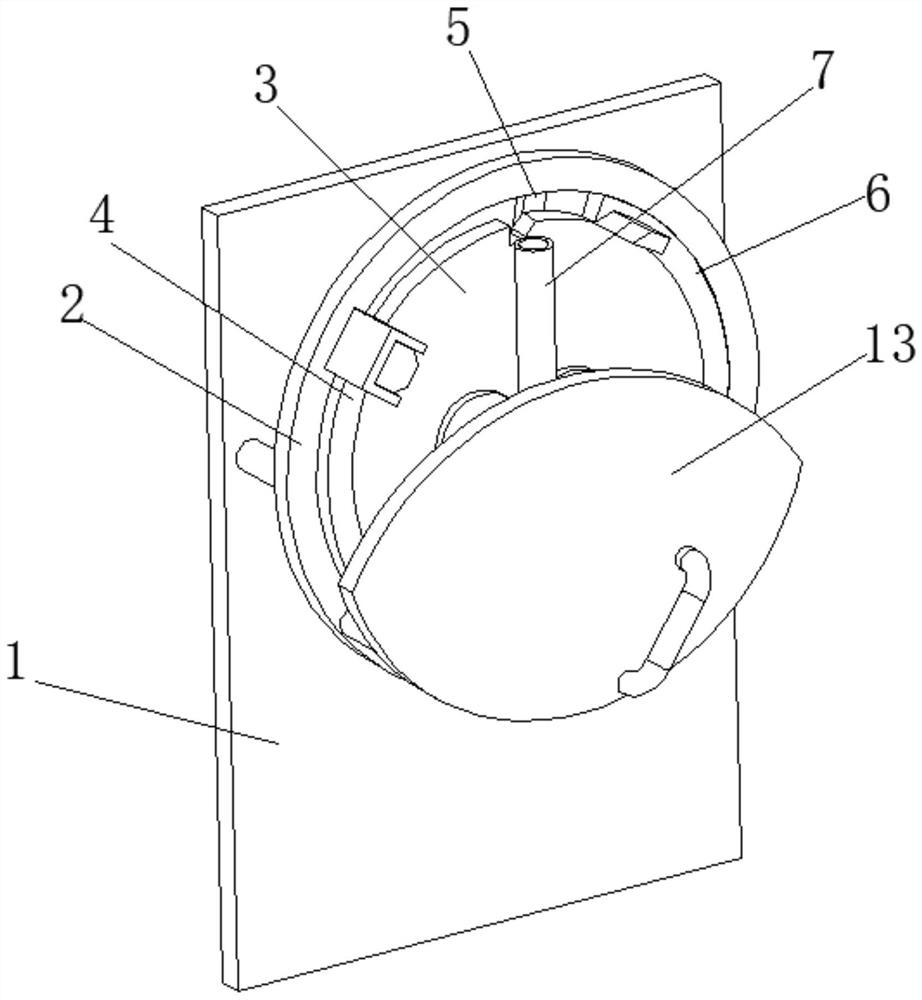

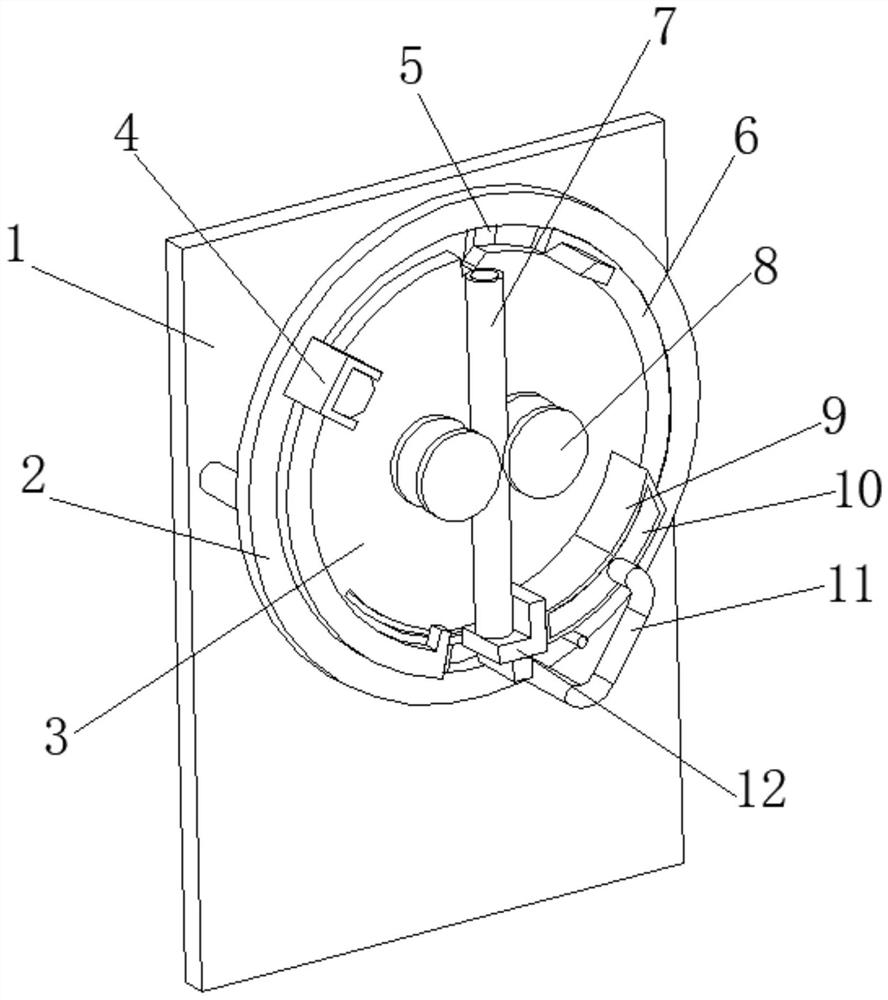

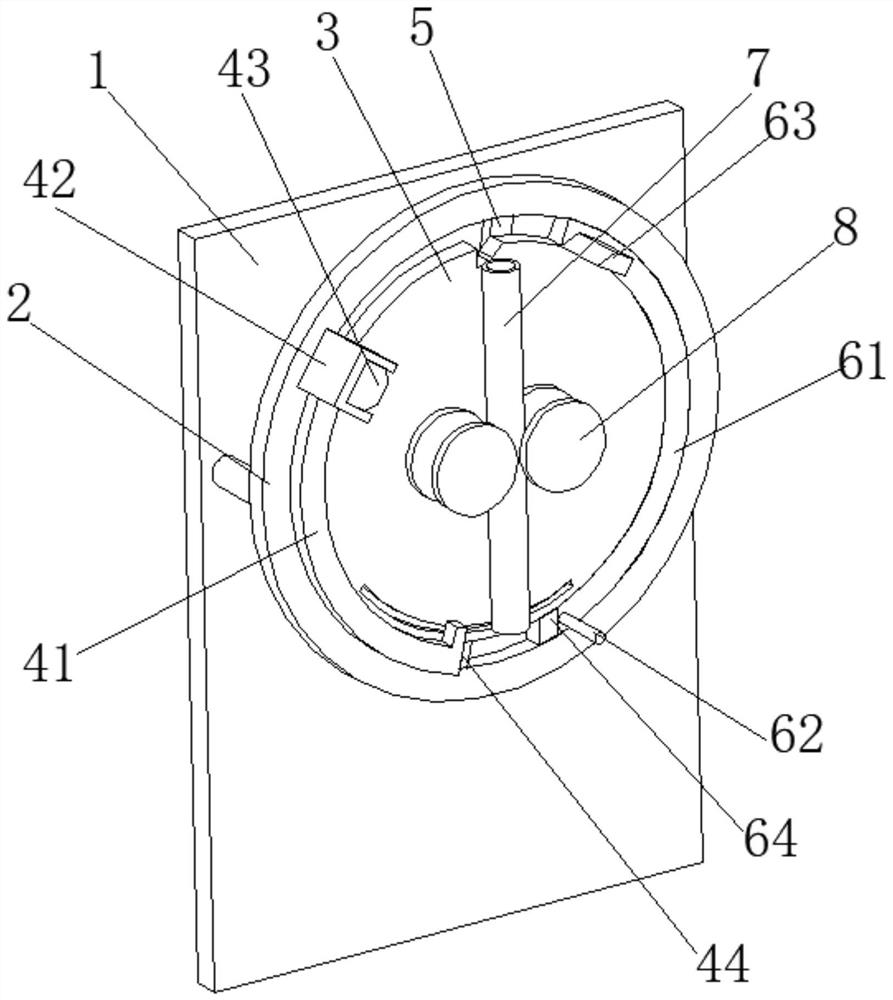

[0025] A plastic pipe bending equipment for construction, such as Figure 1-Figure 5 As shown, including the mounting plate 1, the right side of the mounting plate 1 is respectively welded with a fixed ring 2 and a fixed plate 3 through a connecting rod, and a detection mechanism 4 and a reset mechanism 6 are respectively arranged between the fixed ring 2 and the fixed plate 3, and reset The mechanism 6 is located at the rear of the detection mechanism 4. The right side of the fixed plate 3 is rotatably connected with two transmission rollers 8, and the pipe 7 is movably connected between the two transmission rollers 8. The right side of the fixed plate 3 is slidably connected with a telescopic box 9. , the inner wall of the telescopic box 9 is fixedly connected with an airbag 10, the front part of the telescopic box 9 is fixedly connected with a push block 12, the right side of the fixed ring 2 is welded with a friction plate 13 through a connecting rod, and the right side of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap