Rail transit sand scattering device

A rail transit and buffer device technology, which is applied in the field of rail transit, can solve the problems such as the inability to realize the movement and mixing of sand at different height layers, and achieve the effect of facilitating precise control, avoiding water accumulation and agglomeration, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

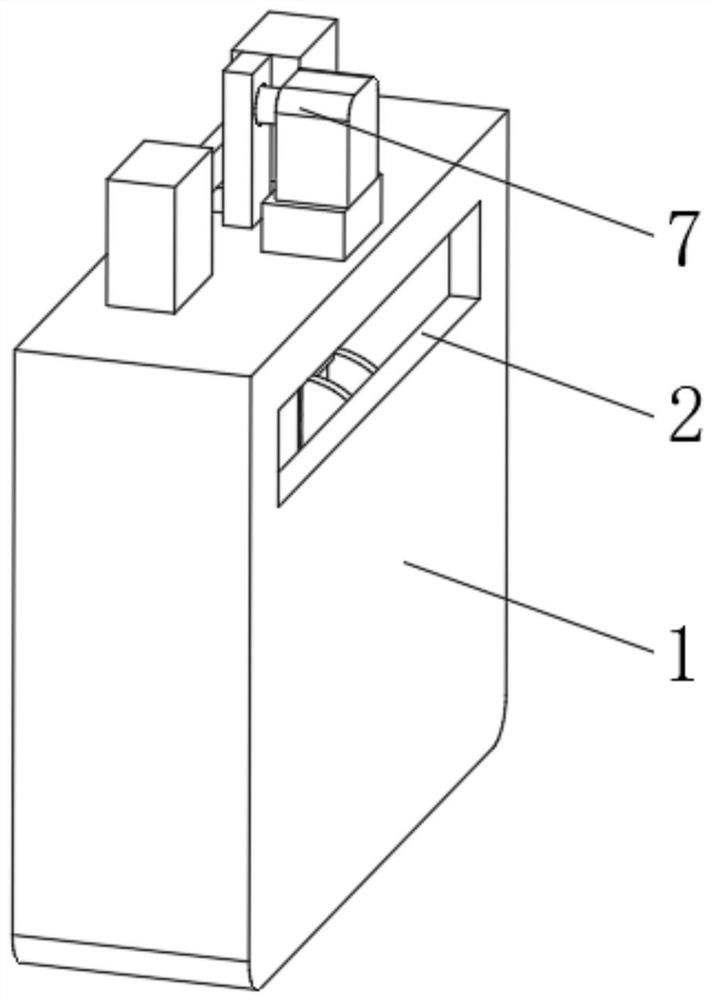

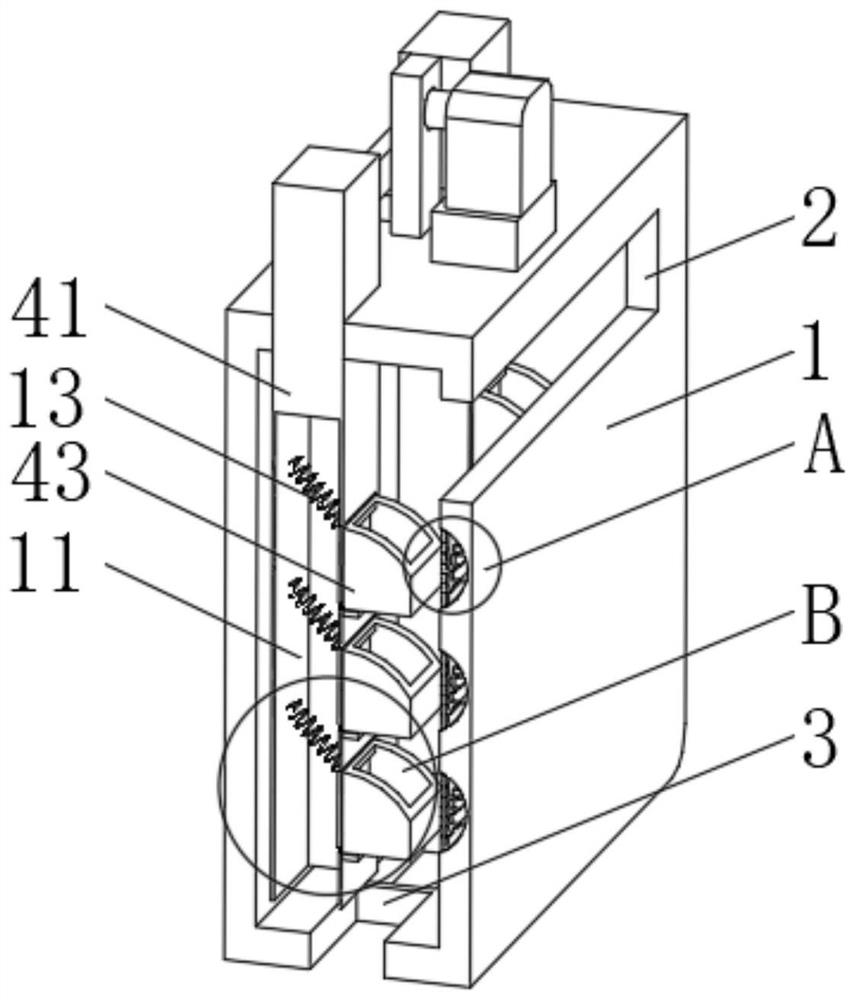

[0032] see Figure 1-6 , the present invention provides a technical solution: a rail transit sand spreading device, comprising a storage bin 1, one side of the storage bin 1 is provided with a feed port 2, and the bottom of the feed port 2 is provided with a discharge port 3, The interior of the storage bin 1 is provided with a refueling device 4, the refueling device 4 has a lifting plate 41, the lifting plate 41 runs through the storage bin 1 and extends to the outside of the storage bin 1, one side of the lifting plate 41 is evenly installed with limited The position plate 42 and the top of the limit plate 42 are rotatably connected with a turning box 43 , and the top of the turning box 43 is provided with a feeding port 44 .

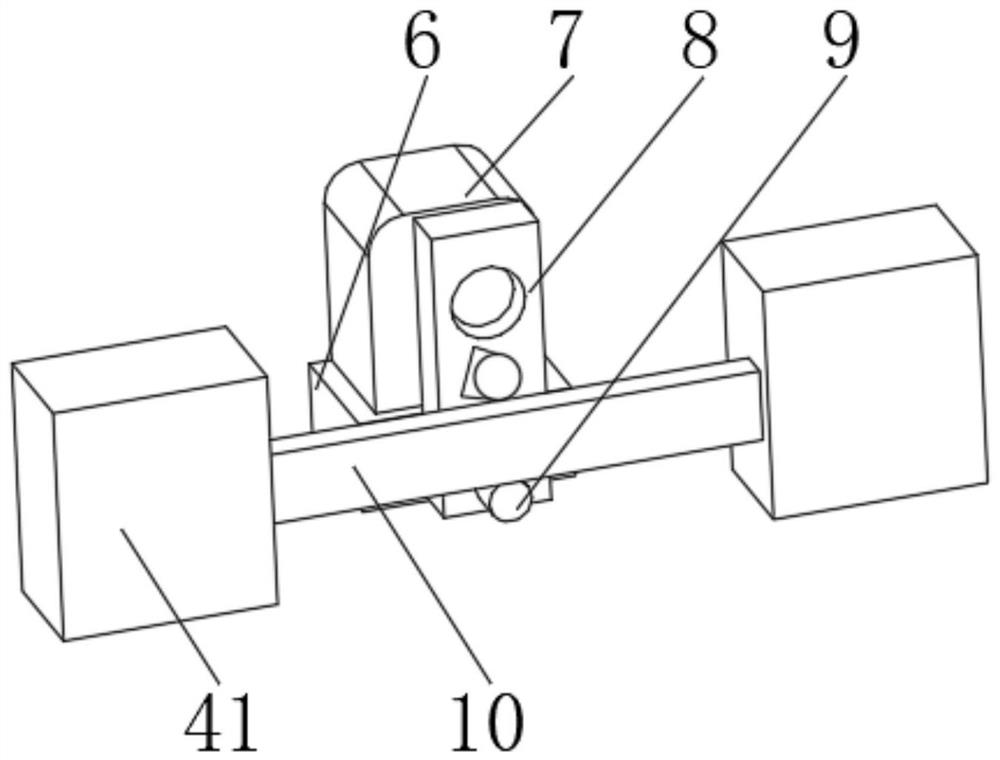

[0033] The top of the storage bin 1 is fixedly connected with a backing plate 6, the top of the backing plate 6 is fixedly connected with a refueling motor 7, and the output end of the refueling motor 7 is fixedly connected with a rotating plate 8, a...

Embodiment 2

[0040] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, a buffer device 5 is provided inside the storage bin 1, and the buffer device 5 has a buffer tank 51, and the buffer tank 51 is set on the inner wall of the storage bin 1. On the side, an elastic membrane 52 is fixedly connected between both sides of the inner wall of the buffer tank 51 , and a wear-resistant plate 53 is evenly installed on the side of the elastic membrane 52 close to the flip box 43 .

[0041] A support spring plate 54 is fixedly connected to one side of the inner wall of the buffer tank 51 , and the support spring plate 54 is connected to the elastic film 52 in a sliding manner.

[0042] When in use, the supporting elastic plate 54 pushes the elastic film 52 and the wear plate 53 to the outside of the buffer tank 51, the lifting plate 41 and the flip box 43 lift and push the sand to move to the inner wall of the storage bin 1, and the wear plate 53 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com