Workpiece transfer device with braking function

A technology for transferring devices and workpieces, which is applied in transportation and packaging, motor vehicles, supporting parts, etc. It can solve the problems of inability to fix workpieces, inconvenience, and adjust the height of workpiece transfer devices, so as to avoid falling, improve transfer quality, and increase friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

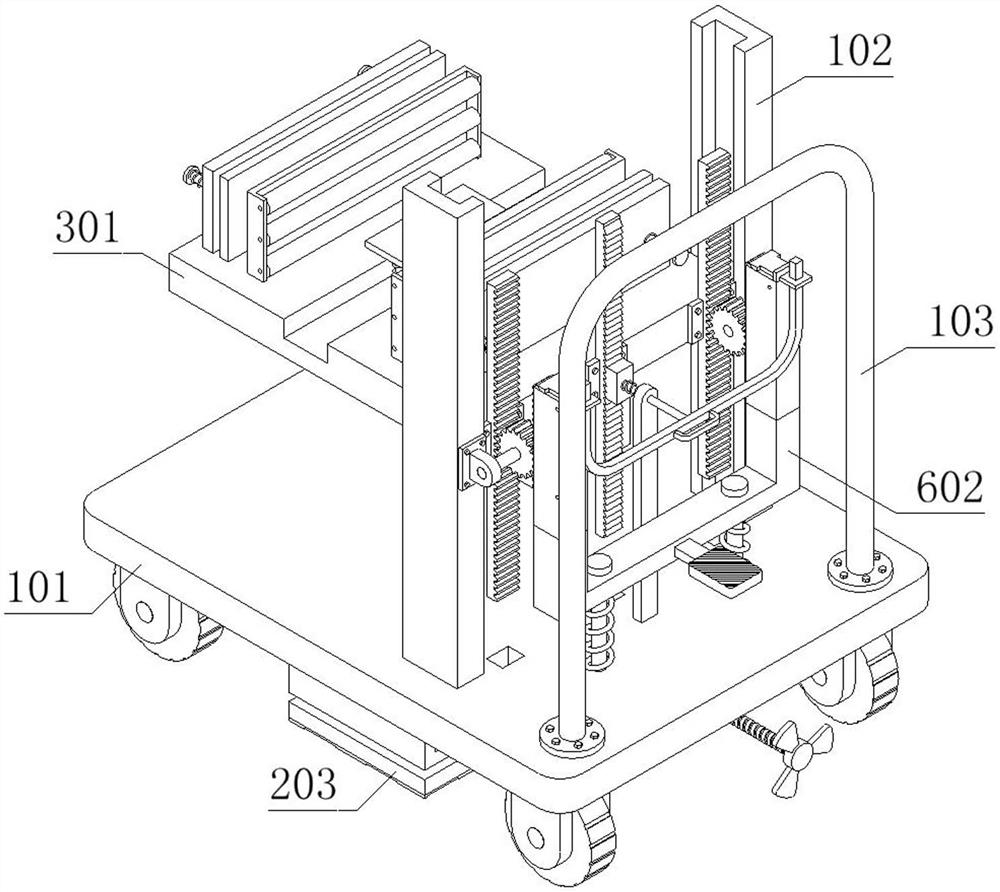

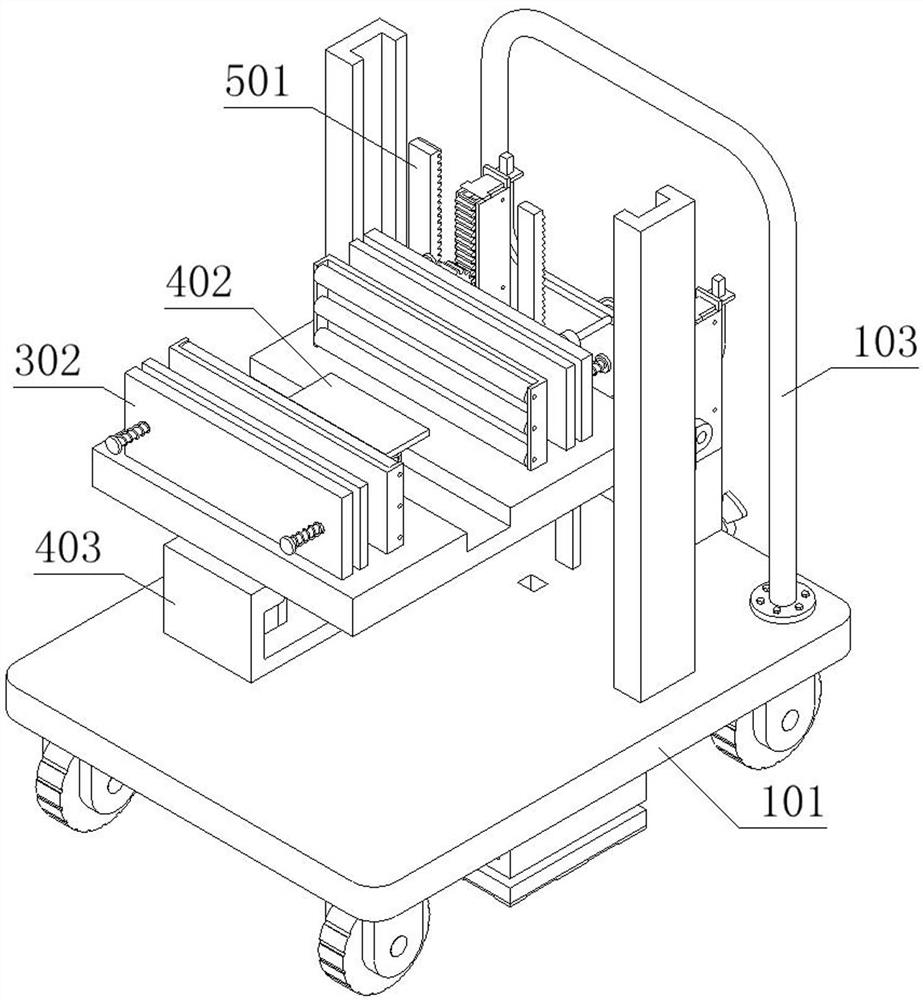

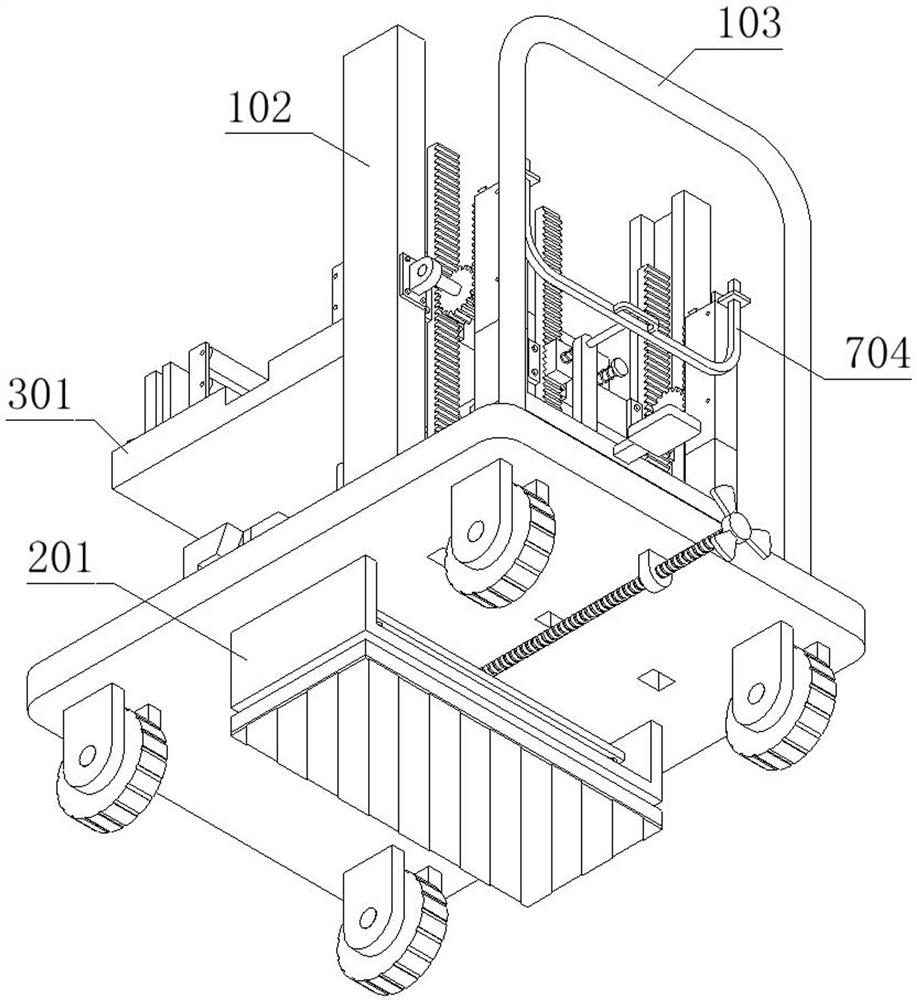

[0076] as attached figure 1 to attach Figure 17 Shown:

[0077] The invention provides a workpiece transfer device with a braking function, which includes a cart main body 1; a braking mechanism 2 is installed on the bottom of the cart main body 1, and a clamping part 3 is installed on the cart main body 1, and the clamping part 3 is equipped with a supporting part 4; connecting mechanism 5, two groups of connecting mechanisms 5 are arranged, and two groups of connecting mechanisms 5 are installed on the right side of clamping part 3; the top of cart main body 1 is equipped with driving part 6 and limit bit part 7.

[0078] Such as Figure 4 and Figure 5 As shown, the cart main body 1 includes: a base 101, four sets of universal wheels are installed on the bottom of the base 101; two slide rails 102, two slide rails 102 are arranged, and the two slide rails 102 are fixedly installed on the top of the base 101 Push rod 103, push rod 103 is fixedly installed on the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com