Building surface flatness detection system and detection method

A detection system and flatness technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as unfavorable overall efficiency and quality of engineering, limited detection area, low detection efficiency, etc., to improve overall efficiency and quality, The effect of convenient operation and increased detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

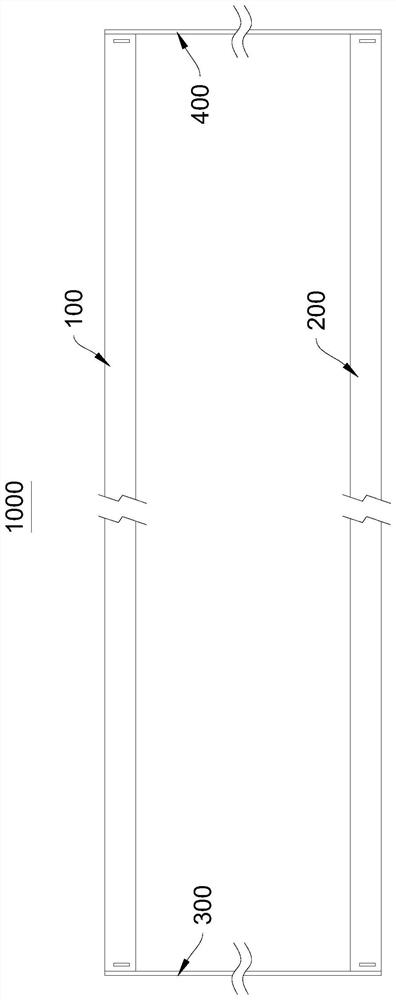

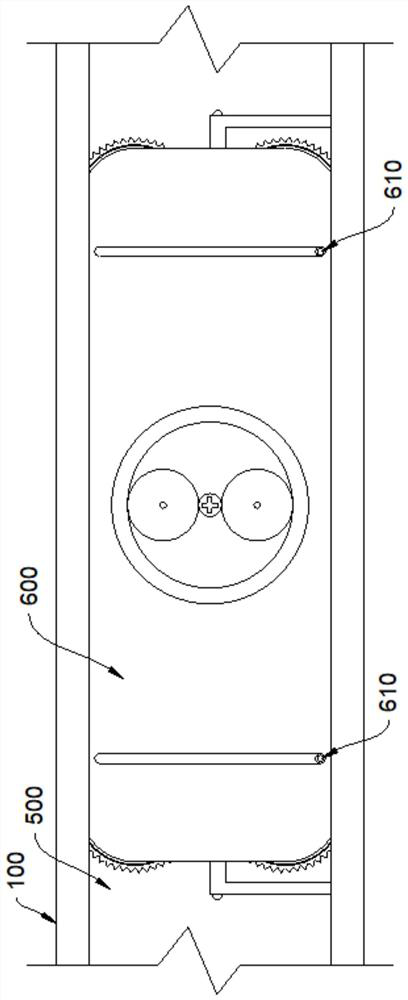

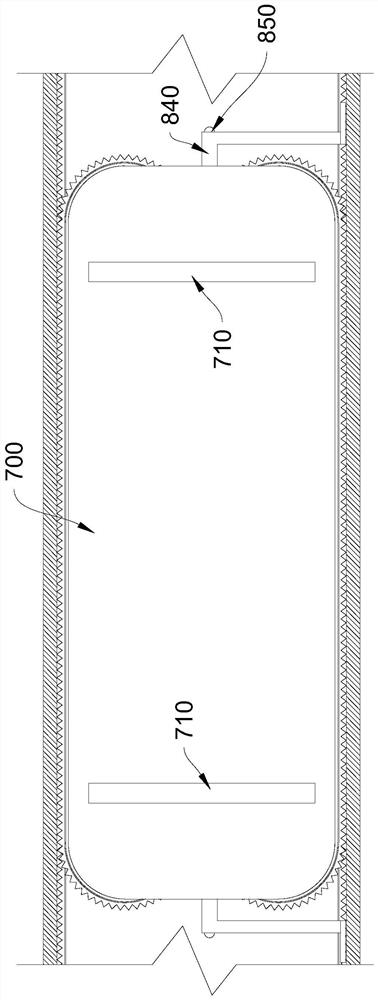

[0056] Please refer to figure 1 , figure 2 and image 3 , the present embodiment provides a building surface flatness detection system 1000, the building surface flatness detection system 1000 includes: a first cross rail 100, a second cross rail 200, a first connecting beam 300, a second connecting beam 400 and Control module (not shown in the figure).

[0057] The first horizontal rail 100 and the second horizontal rail 200 are arranged in parallel and at intervals. Both the first connecting beam 300 and the second connecting beam 400 are connected between the first horizontal rail 100 and the second horizontal rail 200 , and are respectively arranged at two ends of the first horizontal rail 100 and the second horizontal rail 200 . The first connecting beam 300 and the second connecting beam 400 are used to improve the structural stability between the first cross rail 100 and the second cross rail 200, and prevent the first cross rail 100 and the second cross rail 200 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com