An accurate measuring device for the tension of aviation steel cables

A technology of precise measurement and wire rope, which is applied in the direction of tension measurement, etc., can solve the problem of insufficient accuracy of wire tension measurement, and achieve the effect of reducing measurement workload, reasonable scheme, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

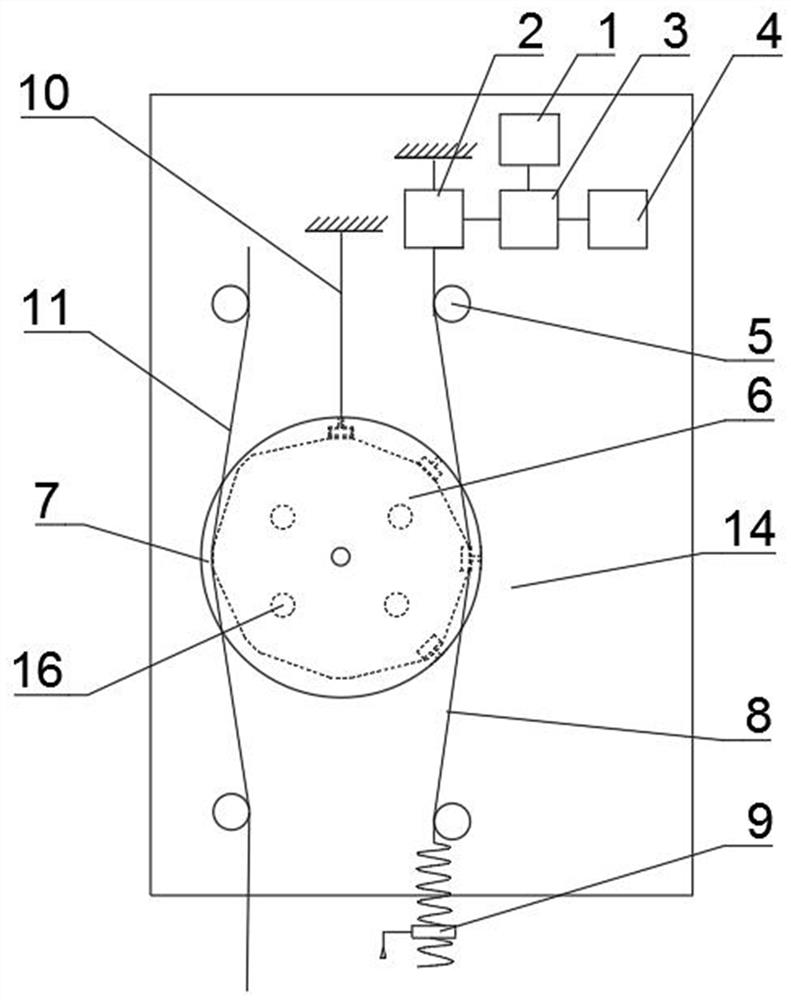

[0059] like Figure 1-Figure 4 shown:

[0060] The present invention provides an accurate measurement device for the tension of an aviation steel cable, comprising a pulley 5, an upper pad 6, a lower pad 7, a force measuring cable 8, a connecting plate 10, a measured cable 11 and a bottom plate 14, wherein:

[0061] The upper cushion block 6 is installed and fixed above the lower cushion block 7;

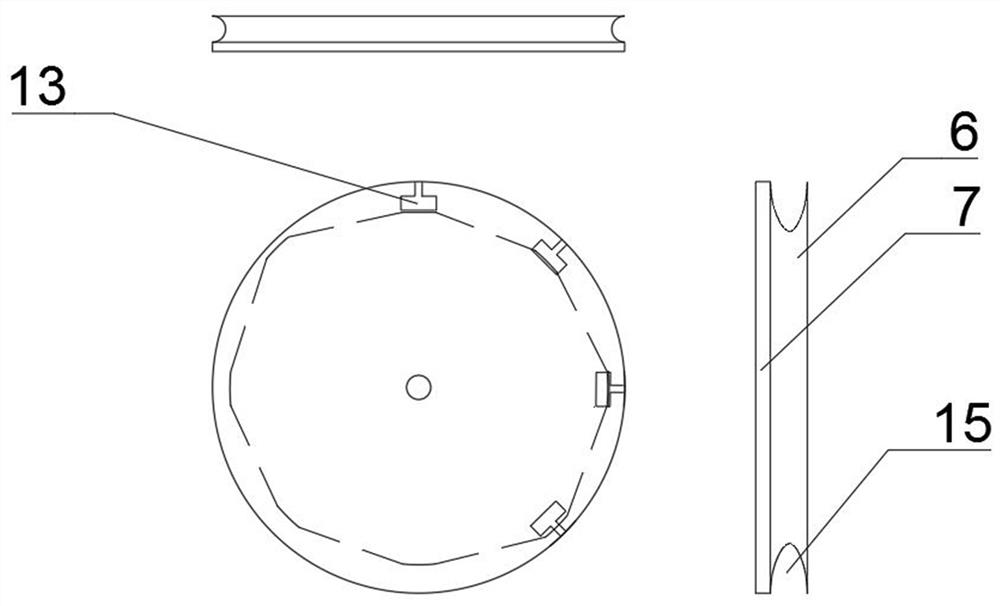

[0062] The upper cushion block 6 is a circular plate-like structure, and the side of the cushion block 6 is provided with a side groove 15;

[0063] The lower cushion block 7 is a circular plate-like structure, and a plurality of T-shaped grooves 13 are formed on the lower cushion block 7;

[0064] The center of the upper cushion block 6 and the lower cushion block 7 are coincident, and a through hole is opened at the center of the circle;

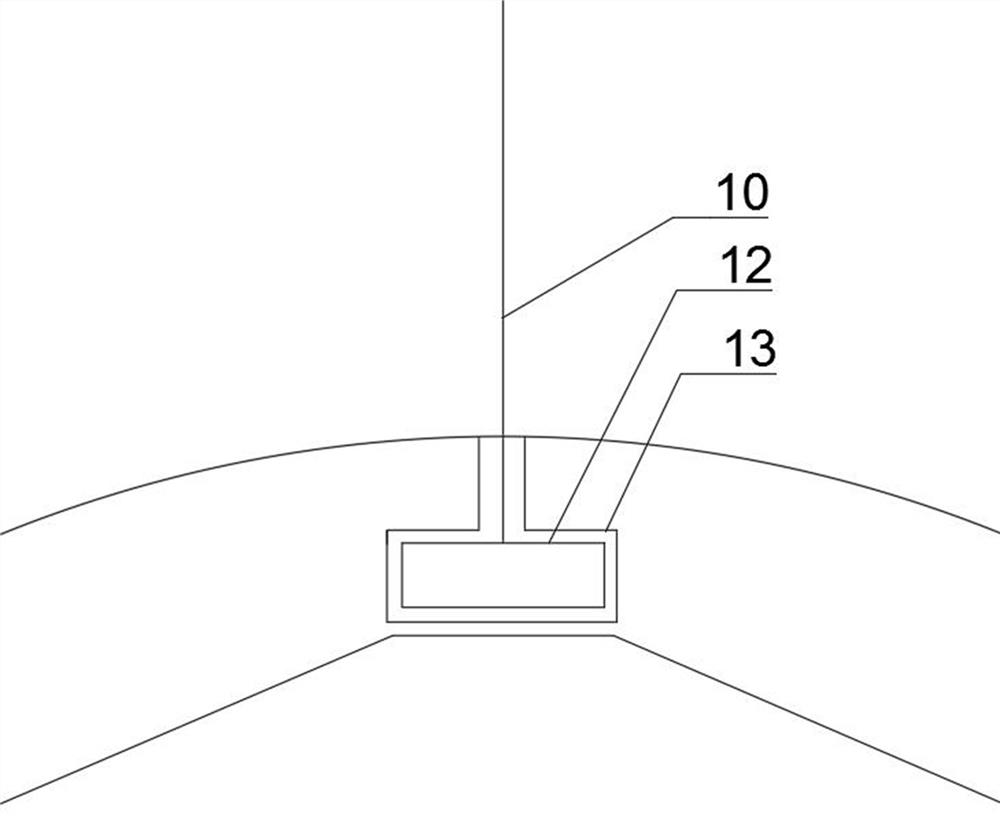

[0065] One end of the connecting plate 10 is fixed on the bottom plate 14, and the other end is provided with a T-shaped piece 12;

[0066]...

Embodiment 2

[0086] The present invention provides an accurate measurement device for the tension of an aviation steel cable, comprising a pulley 5, an upper pad 6, a lower pad 7, a force measuring cable 8, a connecting plate 10, a measured cable 11 and a bottom plate 14, wherein:

[0087] The upper cushion block 6 is installed and fixed above the lower cushion block 7;

[0088] The upper pad 6 is a circular plate-like structure, and the side of the pad 6 is provided with a side groove 15. The depth of the side groove 15 is uneven, and its depth value is related to the upper The center of the circle is symmetrical;

[0089] The lower cushion block 7 is a circular plate-like structure, and a plurality of T-shaped grooves 13 are formed on the lower cushion block 7;

[0090] The center of the upper cushion block 6 and the lower cushion block 7 are coincident, and a through hole is opened at the center of the circle;

[0091] One end of the connecting plate 10 is fixed on the bottom plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com