Method for extracting total chlorogenic acid from photinia fraseri

A technology of total chlorogenic acid and red leaves, which is applied in chemical instruments and methods, separation/purification of carboxylic acid esters, pharmaceutical formulations, etc., can solve the problem of high cost, and achieve the effects of increasing content, reducing loss and improving extraction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0058] Example 1 Experiment of composition analysis of red-leaf heather

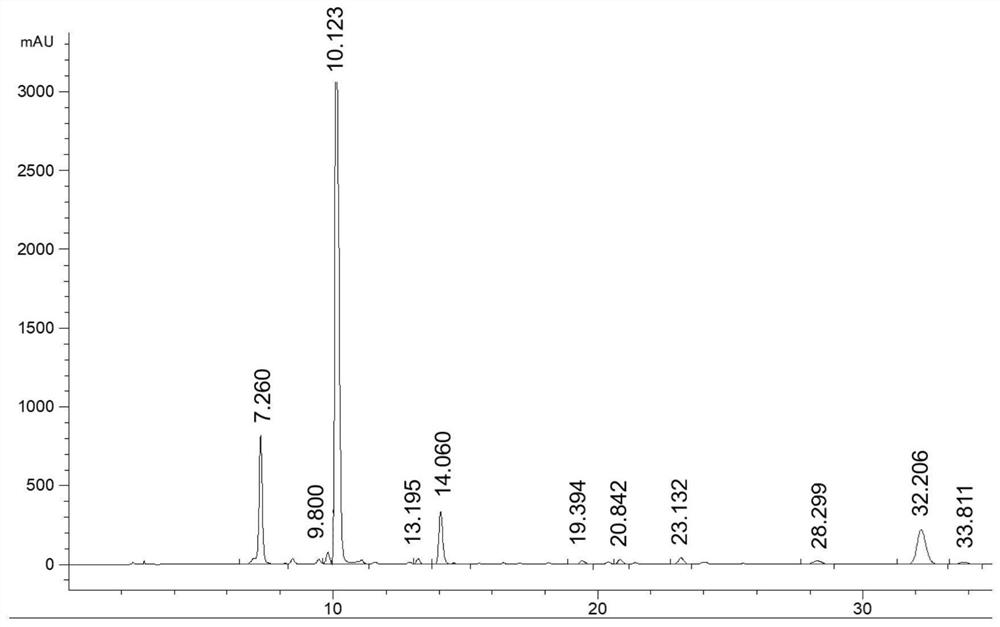

[0059] Bring the harvested leaves of each stage back to the laboratory as soon as possible with clean filter paper to absorb water droplets and remove foreign bodies, cut them into pieces with scissors and weigh 5.00g in a 50ml graduated PET centrifuge tube, add 40ml of 75% ethanol / water solvent , screw the cap, and ultrasonically extract for 30min. The extract was filtered through a 0.5um organic filter, and the filtrate was injected with 2ul for HPLC analysis. The results of analysis and detection of chlorogenic acid content are as follows:

[0060] table 3.

[0061] Sample serial number Neochlorogenic acid (3-CQA) content Chlorogenic acid (5-CQA) content Total Chlorogenic Acid Content 1 1.12% 6.02% 7.14% 2 1.32% 6.74% 8.06% 3 2.48% 3.56% 6.04% 4 3.30% 3.48% 6.78% 5 2.44% 2.84% 5.28% 6 1.20% 1.46% 2.66% 7 1.10% 1.04% 2.14% 8 0.75% ...

Example Embodiment

[0064] Example 2 Drying Mode Screening Experiment

[0065] Harvest 67.5Kg of red-leaf heather shoots and divide them into four batches. 1 batch of bud leaves 2.5Kg is directly sun-dried; 1 batch of bud leaves 2.5Kg is directly dried in the shade; 1 batch of bud leaves is 2.0Kg, directly dried at 85°C; 1 batch of bud leaves is 60Kg, spread out to dry, use tea leaves After the greening machine is heated at 200°C, it is dried by the tea dryer at 85°C. The content of chlorogenic acid in 4 batches of dried shoots and leaves was detected. The test results are as follows:

[0066] Table 4.

[0067] batch drying method sprout leaf weight dry weight dry yield Total chlorogenic acid content in dry product 1 dry in the shade 2.5Kg 0.780Kg 31.2% 6.8% 2 sun dried 2.5Kg 0.755Kg 30.2% 10.2% 3 Direct drying at 85°C 2.0Kg 0.596Kg 29.8% 16.8% 4 Quick drying after finishing 60Kg 17.04Kg 28.4% 18.4%

[0068] Experiments s...

Example Embodiment

[0069] Example 3 Preparation of the young leaf extract of red leaf heather

[0070] Using the red leaves of the red leaf heather as raw materials, prepare according to the following steps:

[0071] (1) After the red buds and leaves of the red leaf heather are killed at a high temperature of 200°C, they are quickly dried at 85°C in a tea dryer to obtain a dry product;

[0072] (2) 10kg of the dry product obtained in step (1) was pulverized, passed through a 10-mesh sieve, added with 120 liters of pure water, stirred and extracted for 60 minutes at 85±5°C, filtered through a 100-mesh stainless steel mesh, and added to 80 liters of pure water in the filter residue, After stirring at room temperature for 30min, filter through a 100-mesh stainless steel filter, and combine the secondary extraction filtrate;

[0073] (3) The combined filtrate is finely filtered by 0.3um ceramic membrane equipment (Shanghai Wodi) to remove particulate impurities, and the finely filtrated permeate is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap