Multifunctional prosthetic eye seat with adjustable microporous structure and its preparation method

A microporous structure and multifunctional technology, applied in the field of biomaterials and medical implants, can solve the problems of unfavorable and rapid vascularization of microstructure and chemical composition, achieve good application value, prevent and control the risk of infection, and reduce postoperative Effects of Complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

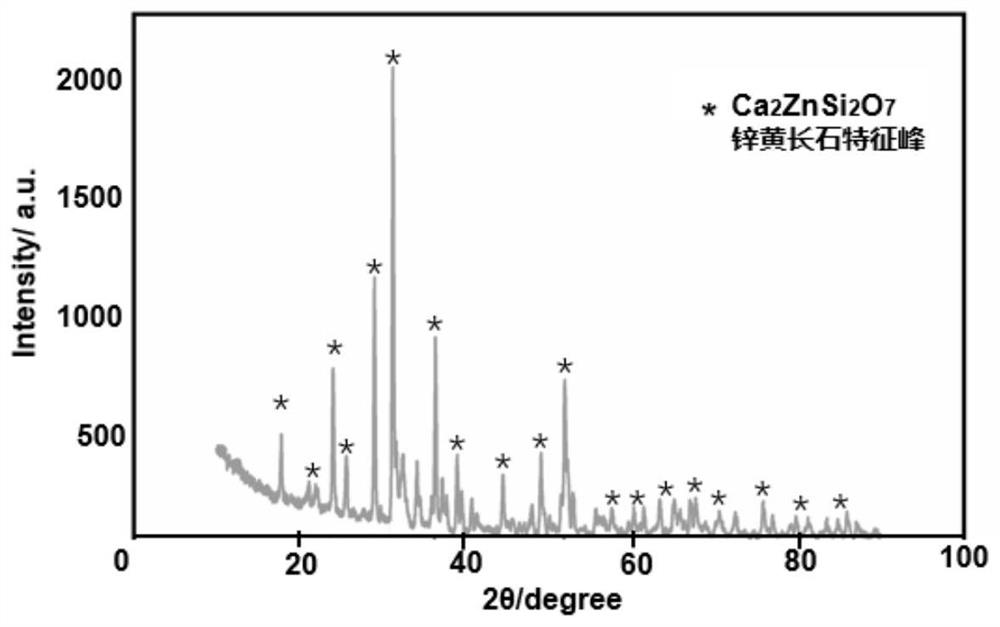

[0046] 1) Mix tetraethyl orthosilicate, deionized water, and nitric acid in a molar ratio of 1:8:0.16, and after continuous stirring and hydrolysis for 30 minutes, add calcium nitrate and zinc nitrate reagents into the mixed solution in turn, and let the nitric acid The molar ratio of calcium, zinc nitrate, and ethyl orthosilicate is 2:1:2, continue stirring for 3 hours until the solution turns into a gel state, and then age and dry at 60 °C and 120 °C for 18 hours and 36 hours. 1250°C for 3 hours, and the obtained kesterite powder was ball-milled in an ethanol medium for 6 hours to obtain an ultrafine powder with a particle size of 10 μm or less.

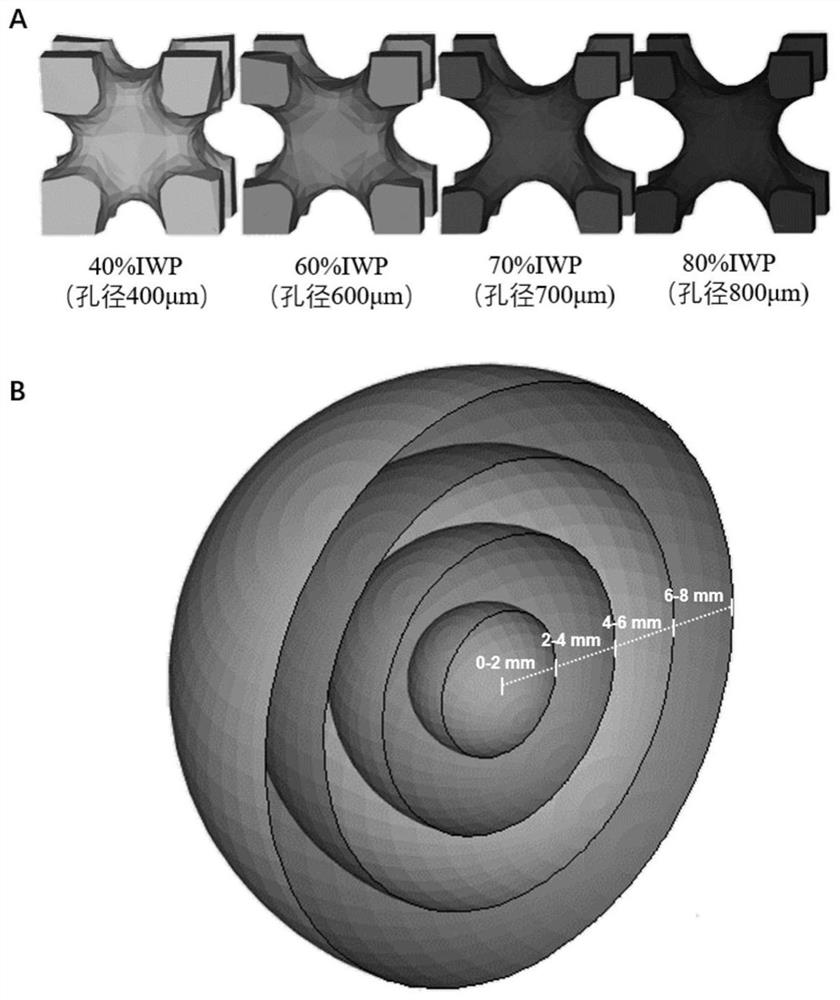

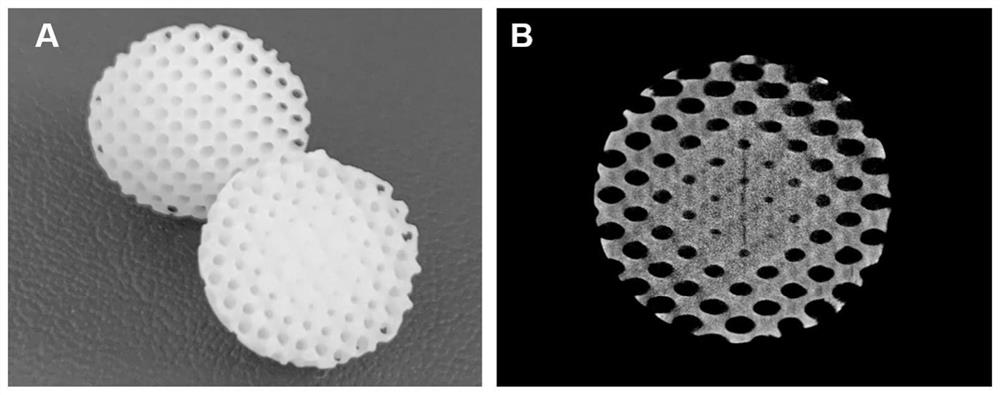

[0047] 2) Weigh the ultra-fine yellow feldspar powder obtained in the above step 1) and add it to the liquid photosensitive printing resin. The mass ratio of the resin and the powder is 1:2, fully mixing by mechanical stirring, and then using digital light to process the three-dimensional printing process It is printed according to...

Embodiment 2

[0057] The preparation method is the same as that of Example 1, except that: in step 2, the internal microporous structure of the prosthetic eye seat is designed to be a Gyroid surface hole cell structure ( Figure 9 ), and in the range of 0~2.0mm, 2.0~4.0mm, 4.0~6.0mm, and the outer layer larger than 6.0mm from the center, respectively use 40% Gyroid (aperture 200μm), 60% Gyroid (aperture 300μm), 70% Gyroid (pore size 500 μm) and 80% Gyroid (pore size 600 μm) form a gradient structure with gradually increasing pore size.

Embodiment 3

[0059] The preparation method is the same as that in Example 1, except that in step 1) tetraethyl orthosilicate, deionized water, and nitric acid are mixed in a molar ratio of 1:8:0.16, and after continuous stirring and hydrolysis for 30 minutes, calcium nitrate, nitric acid The copper and zinc nitrate reagents were added to the mixed solution in turn, and the molar ratio of calcium nitrate, copper nitrate, zinc nitrate, and ethyl orthosilicate was 1.95:0.05:1:2, and stirring was continued for 5 hours until the solution was converted into coagulation. colloidal state, then aged and dried at 60 °C and 120 °C for 24 hours and 60 hours in turn, and then calcined at 1250 °C for 3 hours. Ultrafine powder below 10μm.

[0060] ICP element analysis of the copper-doped feldspar powder in this example shows that the content of copper in the powder is 1.11 ppm, and the molar ratio to the content of calcium is 1.95:0.0468, which is consistent with the theoretical value (Table 1).

[0061...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com