Coal mill coal blockage fault judgment and fault self-healing method and system

A fault self-healing and fault judgment technology, applied in grain processing, etc., can solve problems such as untimely maintenance, low degree of automation, and poor reliability, so as to save time for analyzing the cause of faults, improve accuracy, reliability, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

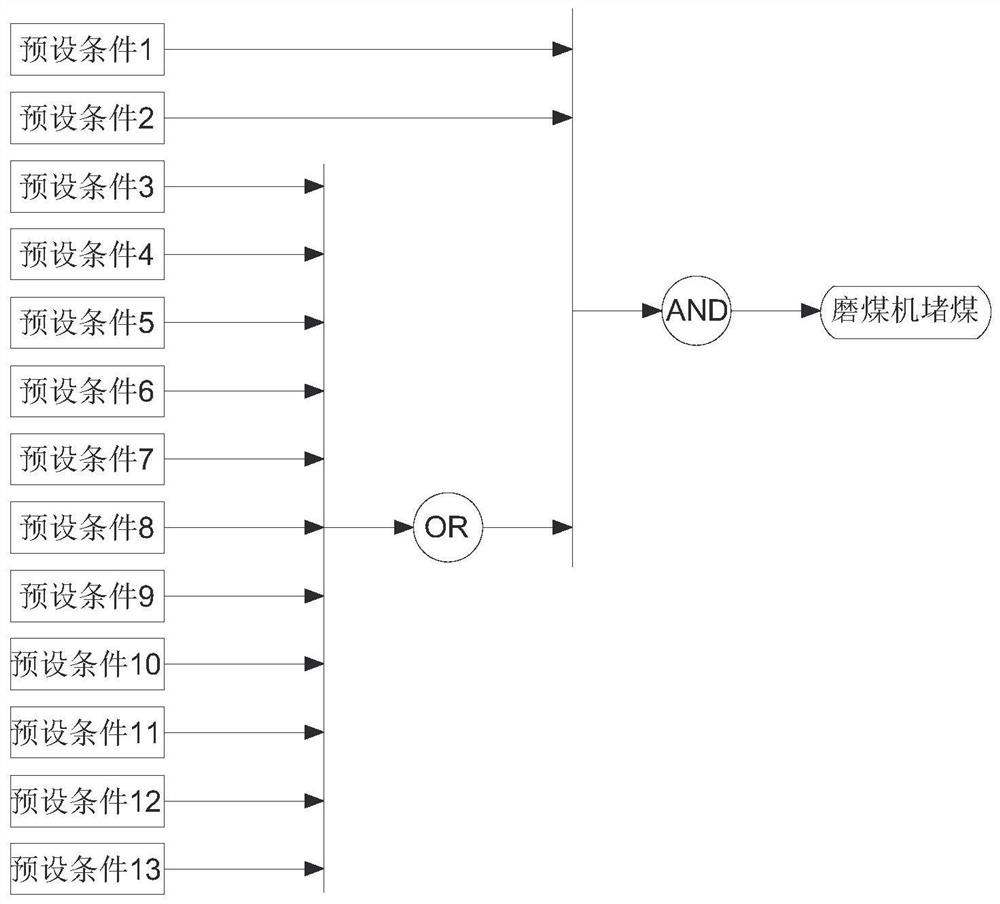

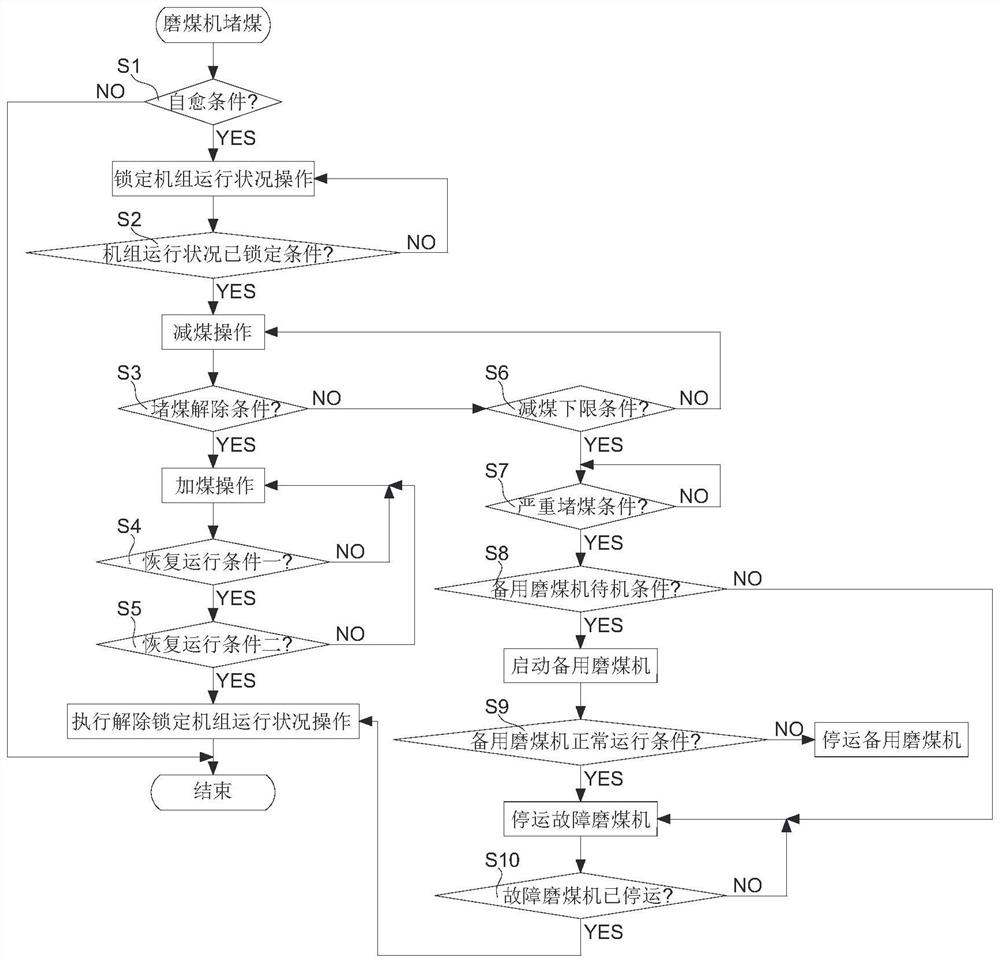

[0093] Such as figure 1 , figure 2 A method for judging and self-healing faults of coal blockage in coal mills shown includes the following steps:

[0094] (1) Feature extraction: monitor the working status data of the coal mill through the monitoring equipment set at each measuring point of the coal mill;

[0095] The working status data in the feature extraction includes the start and stop signal of the coal mill, the opening of the hot air door at the entrance of the coal mill, the air volume at the entrance of the coal mill, the current of the coal mill, the temperature at the exit of the coal mill, the pressure at the exit of the coal mill, and the inlet pressure.

[0096] (2) Logical judgment: through the diagnostic system, the working status data monitored in step (1) feature extraction is calculated and analyzed according to the judgment logic of the coal blocking fault, and it is judged whether the coal blocking fault occurs;

[0097] The judgment logic of coal bl...

Embodiment 2

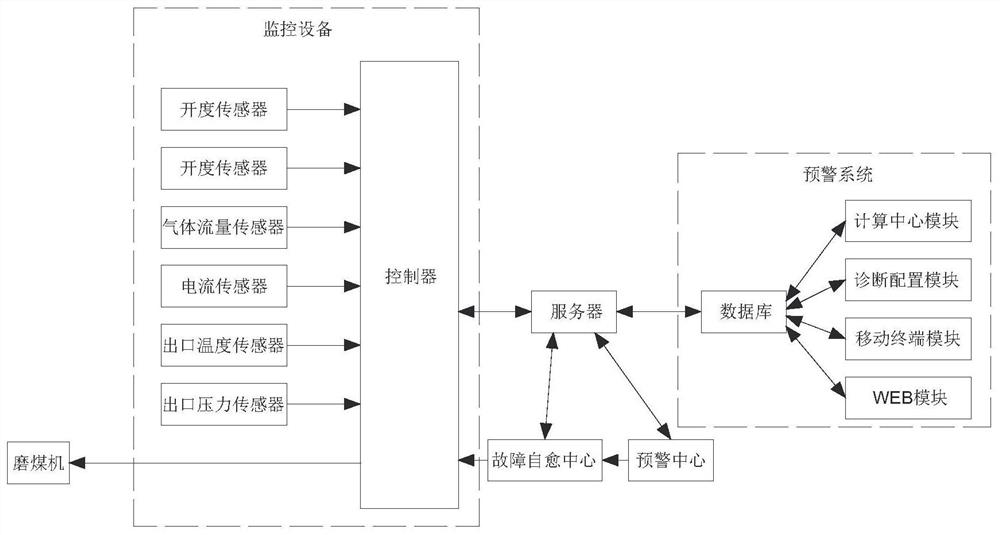

[0159] Such as image 3 A coal pulverizer coal blocking fault judgment and fault self-healing system is shown, including a coal pulverizer, monitoring equipment, a server, a diagnosis system, an early warning center, and a fault self-healing center;

[0160] The monitoring equipment includes an opening sensor at the hot air door at the coal mill inlet, a gas flow sensor at the coal mill inlet, a current sensor at the output end of the coal mill motor, and an outlet temperature sensor at the coal mill outlet. A sensor, an outlet pressure sensor arranged at the outlet of the coal mill, an inlet pressure sensor arranged at the inlet of the coal mill and a controller.

[0161] The monitoring equipment is used to monitor the working status data of the coal mill, and then upload the working status data to the server, and the controller controls the coal mill according to the control instructions sent by the server;

[0162] The server performs data exchange with the monitoring equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com