Method and device for realizing gradual change of logo pattern of lip glaze pipe

A realization method and pattern technology, which can be applied to printing devices, printing of special types of printed matter, printing, etc., can solve the problem of unsightly printing of the logo of lip gloss tubes, and achieve strong market competitiveness and beautiful visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

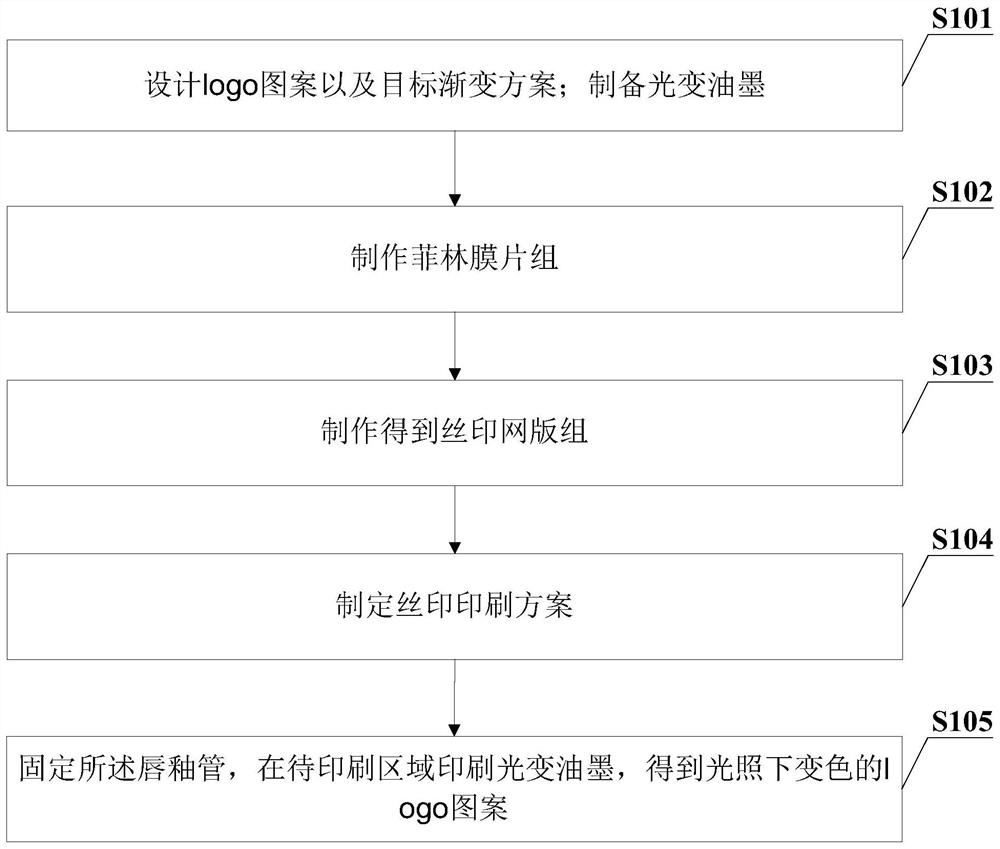

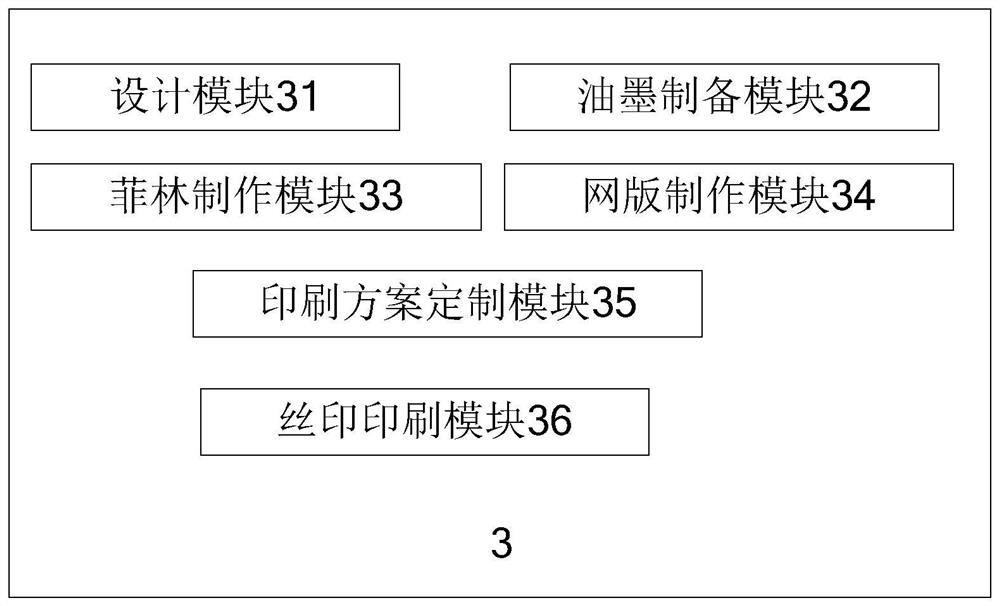

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. This embodiment provides a method for realizing the gradual change of the logo pattern of the lip gloss tube. By this method, a logo with a gradient effect can be screen-printed on the lip gloss tube provided in this embodiment.

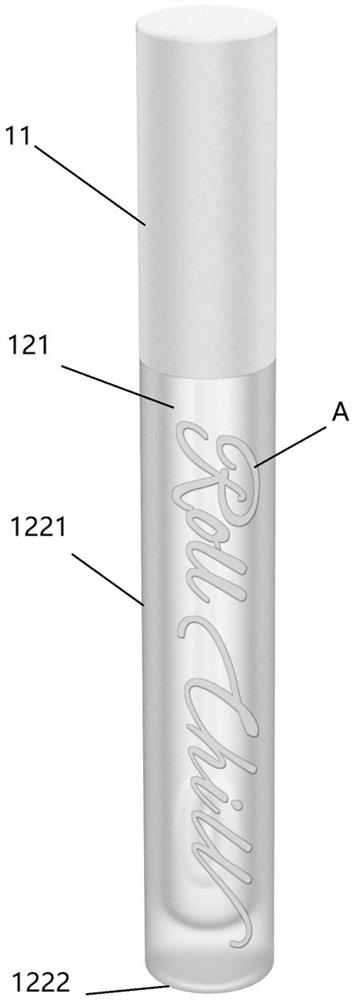

[0031] See figure 1 As shown, the structure of the lip gloss tube in this embodiment is shown. The lip gloss tube includes a tube head 11 and a tube body. The tube body includes an inner tube 121 and an outer tube. The inner tube 121 and the outer tube are both hollow cylinders. The diameter of the tube 121 is smaller than that of the outer tube, and the inner tube 121 and the outer tube are coaxially fitted into a double-layer concentric cylinder structure.

[0032] Both the inner tube 121 and the outer tube are made of polymer plastics, such as PETG (polyethylene te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com