Bearing part transporting frame

A technology for transport racks and parts, applied in the field of transport racks, to achieve the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

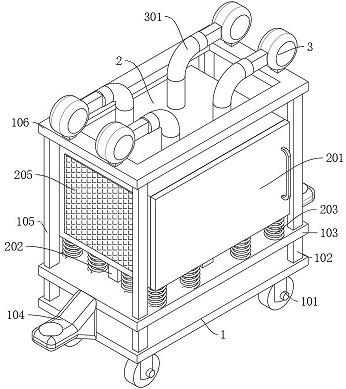

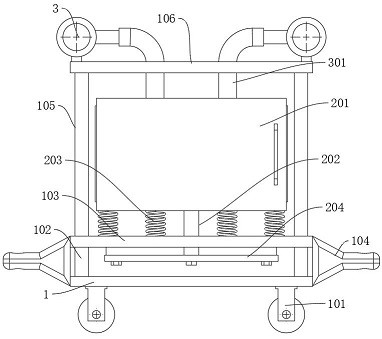

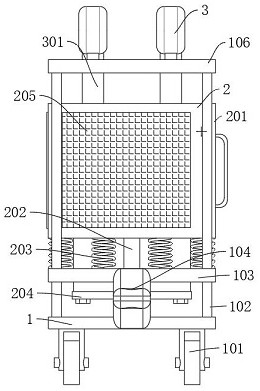

[0024] refer to Figure 1-Figure 7 , a bearing parts transport rack, including a base, a box body 2 is elastically arranged on the base, an opening is provided at one end of the box body 2, and a box door 201 is arranged at the opening, and three vertical plates 4 are fixedly connected in the box body 2, The three vertical boards 4 are equidistantly arranged in the box body 2; the three vertical boards 4 are fixedly connected with a cross bar 401 close to the opening of the box body 2, and the two ends of the cross bar 401 are respectively fixed to the two inner side walls of the box body 2 And three vertical boards 4 are penetrated sequentially, and a chamber is formed between a plurality of vertical boards 4. After the cross bar 401 intersects with a plurality of vertical boards 4, the chamber is divided into a feeding port 406 and a storage chamber. In the box for storing bearing parts; the cross bar 401 is provided with an elastic buffer plate 408 , and the elastic buffer ...

Embodiment 2

[0026] refer to Figure 1-Figure 7 , a bearing parts transport rack, including a base, a box body 2 is elastically arranged on the base, an opening is provided at one end of the box body 2, and a box door 201 is arranged at the opening, and three vertical plates 4 are fixedly connected in the box body 2, The three vertical boards 4 are equidistantly arranged in the box body 2; the three vertical boards 4 are fixedly connected with a cross bar 401 close to the opening of the box body 2, and the two ends of the cross bar 401 are respectively fixed to the two inner side walls of the box body 2 And three vertical boards 4 are penetrated sequentially, and a chamber is formed between a plurality of vertical boards 4. After the cross bar 401 intersects with a plurality of vertical boards 4, the chamber is divided into a feeding port 406 and a storage chamber. In the box body for storing bearing parts; the cross bar 401 is provided with an elastic buffer plate 408, the elastic buffer ...

Embodiment 3

[0029] refer to Figure 1-Figure 7 , a bearing parts transport rack, including a base, a box body 2 is elastically arranged on the base, an opening is provided at one end of the box body 2, and a box door 201 is arranged at the opening, and three vertical plates 4 are fixedly connected in the box body 2, The three vertical boards 4 are equidistantly arranged in the box body 2; the three vertical boards 4 are fixedly connected with a cross bar 401 close to the opening of the box body 2, and the two ends of the cross bar 401 are respectively fixed to the two inner side walls of the box body 2 And three vertical boards 4 are penetrated sequentially, and a chamber is formed between a plurality of vertical boards 4. After the cross bar 401 intersects with a plurality of vertical boards 4, the chamber is divided into a feeding port 406 and a storage chamber. In the box for storing bearing parts; the cross bar 401 is provided with an elastic buffer plate 408, the elastic buffer plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com