Weighing type mixing and packaging sealing machine

A sealing machine and material mixing technology, which is applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of inability to achieve accurate quantitative weighing of packaging, unstable work, and distribution of weight, etc., to achieve efficient and convenient material transportation , improve work efficiency, and quickly transport materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

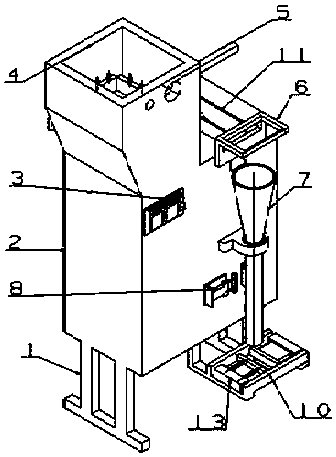

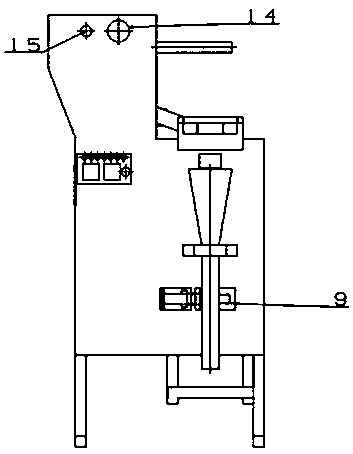

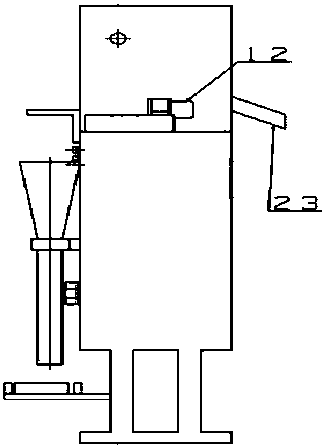

[0028] like Figure 1~5 As shown, this embodiment provides a weighing type mixing packaging and sealing machine, which includes a box body 2, a hopper 4 is arranged on the top of the box body 2, and a base 1 is arranged on the bottom. A coarse feeding port 14 and a fine feeding port 15 are provided on the hopper 4 , a weighing platform 16 is located below the hopper 4 , and a weight sensor 17 is installed below the weighing platform 16 . The weighing platform 16 is connected with a receiving chute 18 and a waste chute 23. Specifically, the receiving chute 18 and the waste chute 23 are slopes with a wide top and a narrow bottom, and guardrails are provided on both sides to prevent materials from running out.

[0029] In the present embodiment, the weighing platform 16 is provided with a first push plate 19 and a second push plate 21 for pushing materials to the receiving chute 18 and the waste chute 23 respectively; A first baffle 20 is provided at the position, and a second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com