Polymer composite paperboard and production equipment thereof

A technology for composite cardboard and production equipment, which is applied in special paper, paper, papermaking, etc. It can solve the problems of adhesives not being completely dry, folds at the bends of composite paper, and low overall toughness, so as to improve the drying effect , Improve the drying degree and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

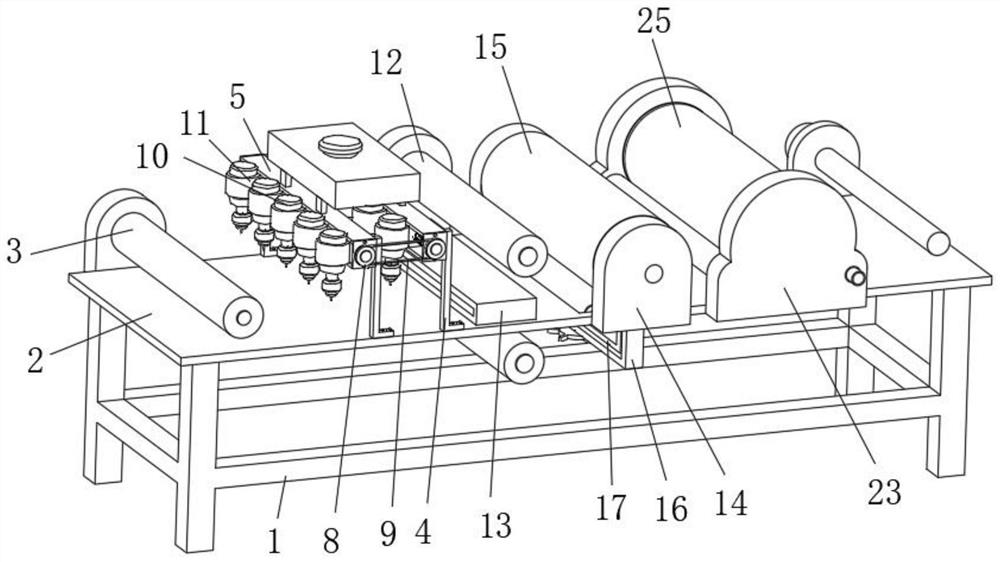

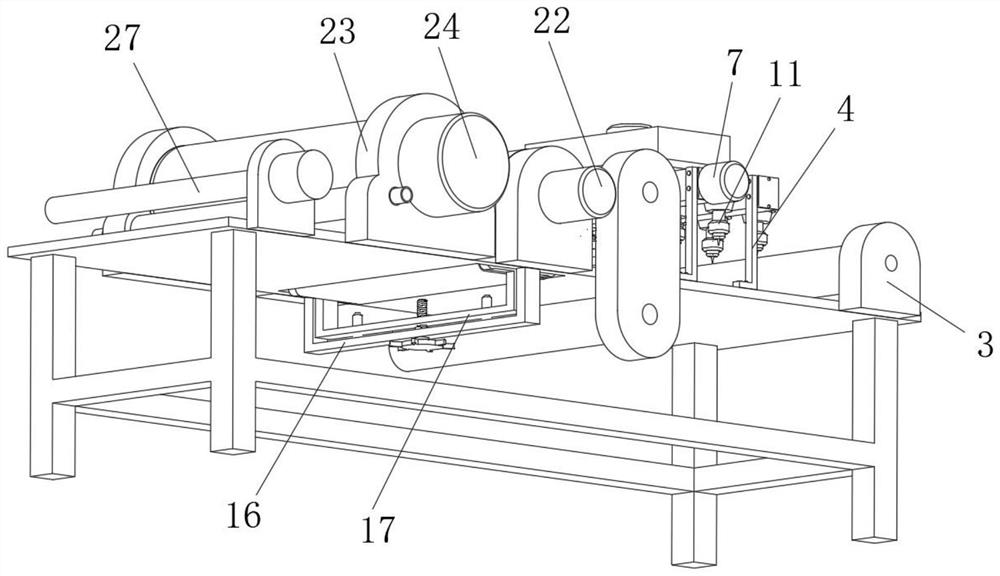

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

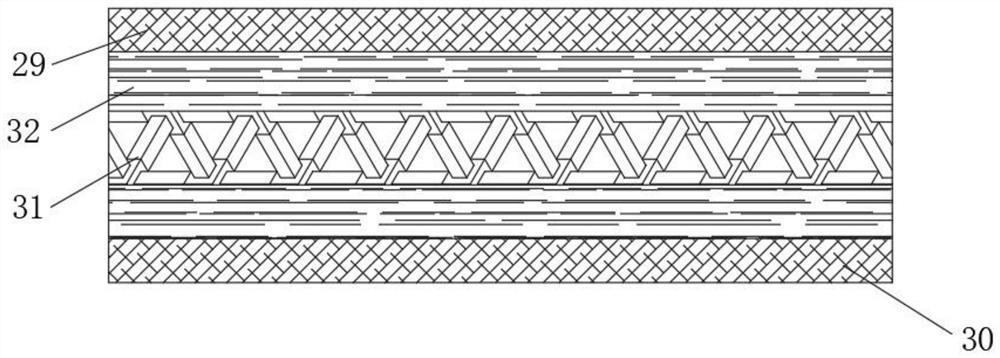

[0028] see Figure 1 to Figure 7 , the present embodiment discloses a polymer composite cardboard and its production equipment, the polymer composite cardboard includes a main core layer 31, the upper and lower sides of the main core layer 31 are covered with glued layers 32, the main core layer 31 The upper and lower sides are respectively bonded with a surface paper layer 29 and a bottom paper layer 30 through an adhesive layer 32 , and the adhesive layer 32 is evenly coated on the upper and lower surfaces of the main core layer 31 .

[0029] Gluing layer 32 is degradable plant starch glue, surface paper layer 29 is made of metal material, such as aluminum foil or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com