Sieving type scattering environment-friendly anthracite preparation device

A preparation device and technology for anthracite, which is applied in material forming presses, sieves, manufacturing tools, etc., can solve the problems of anthracite particles and rice husk particles that cannot be uniformly distributed, are easily rolled into a whole block, and affect processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

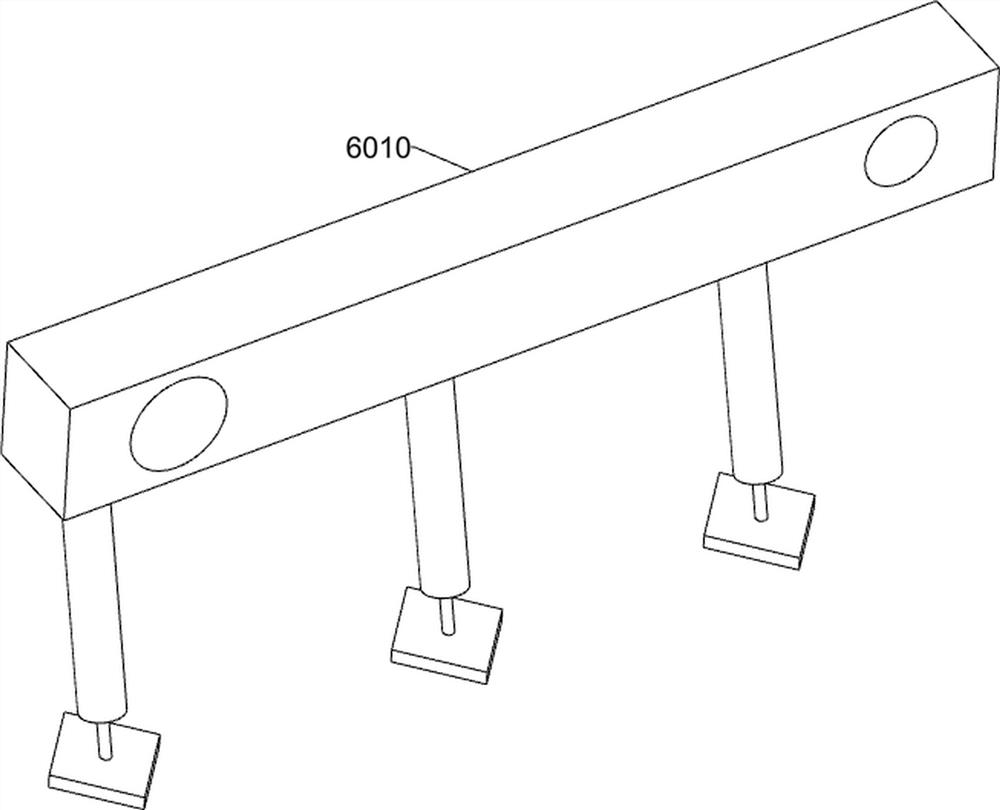

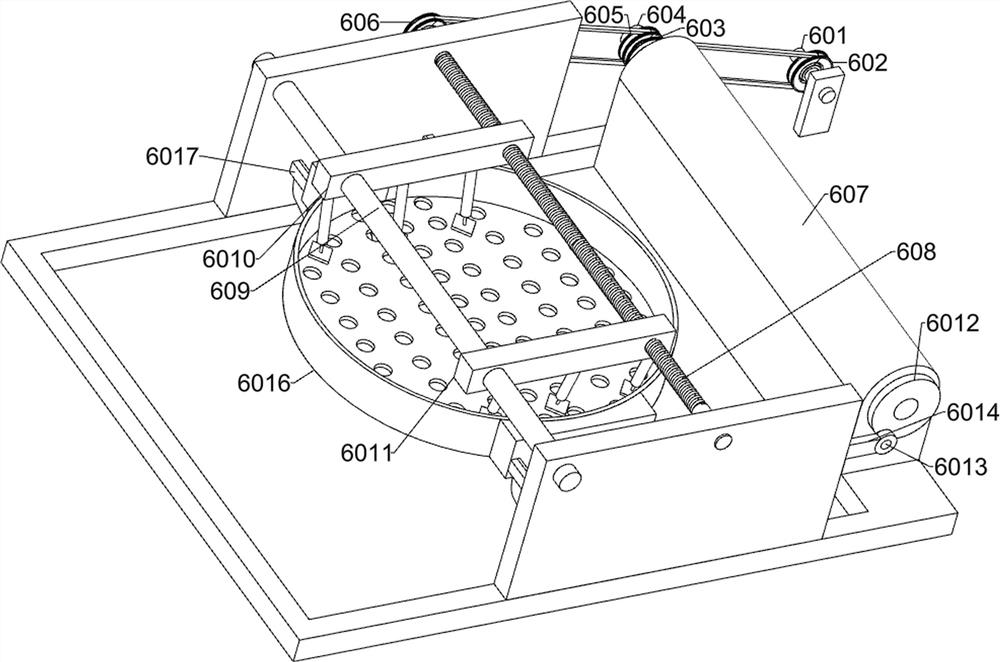

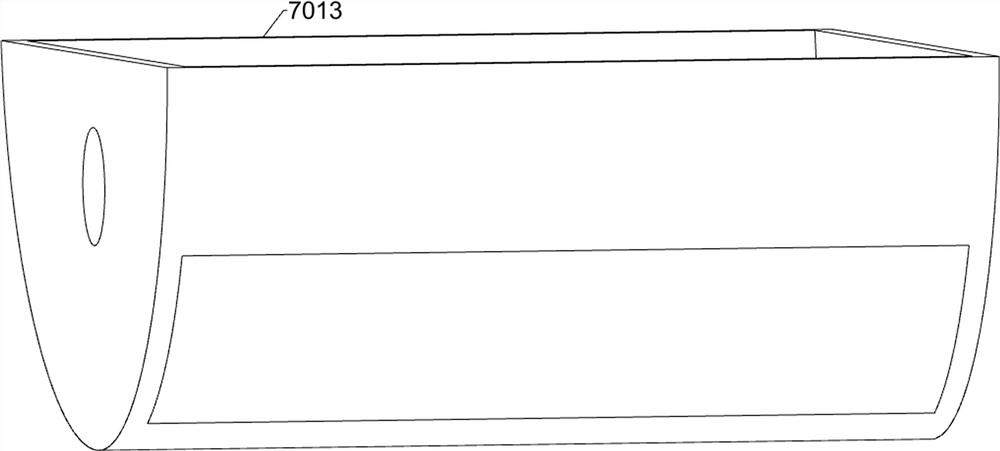

[0038] A sieve-type spraying environment-friendly anthracite preparation device, refer to Figure 1-3 As shown, it includes a support frame, a controller, a first motor, a second motor, a grinding mechanism, a spreading mechanism, a first material inlet, a second material inlet, a grinding table, a first feeding table, a first electric motor A push rod, a second electric push rod, a filter screen, a raw material collection box and a molded coal collection box; the support frame is fixedly connected to the controller; the support frame is fixedly connected to the first motor; the support frame is fixedly connected to the second motor; A grinding mechanism is arranged above and inside the support frame; the first motor is fixedly connected to the grinding mechanism; when the grinding mechanism grinds wet anthracite particles and rice husk particles, it can prevent the anthracite particles and rice husk particles from sticking into blocks; the support frame There is a material sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com