Efficient energy-saving rail type lithium battery baking oven

A high-efficiency, energy-saving, rail-type technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, drying, etc., can solve problems such as environmental impact, poor fixing effect, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

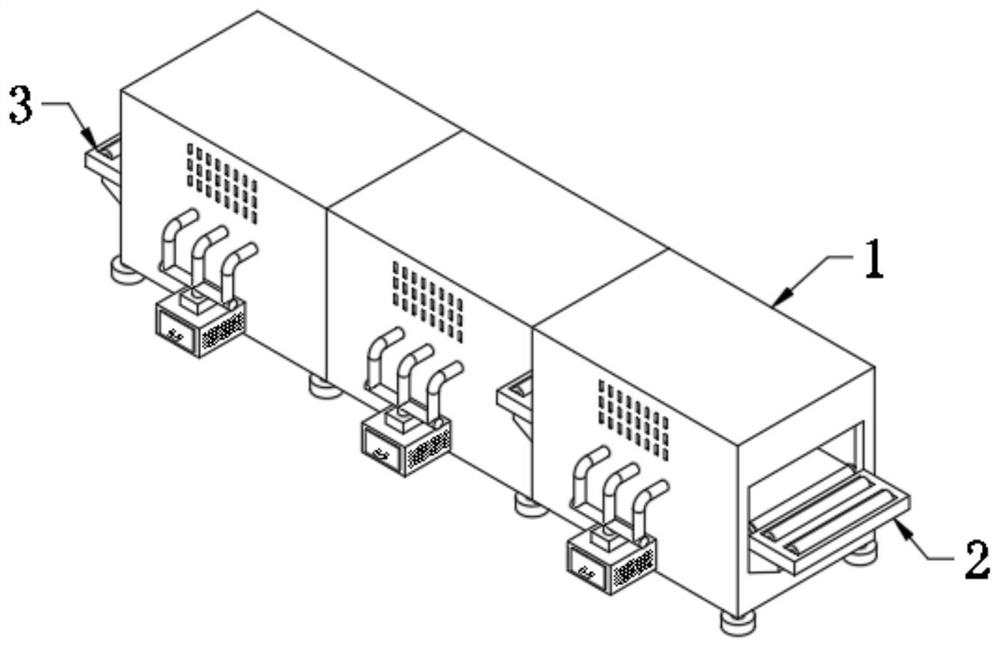

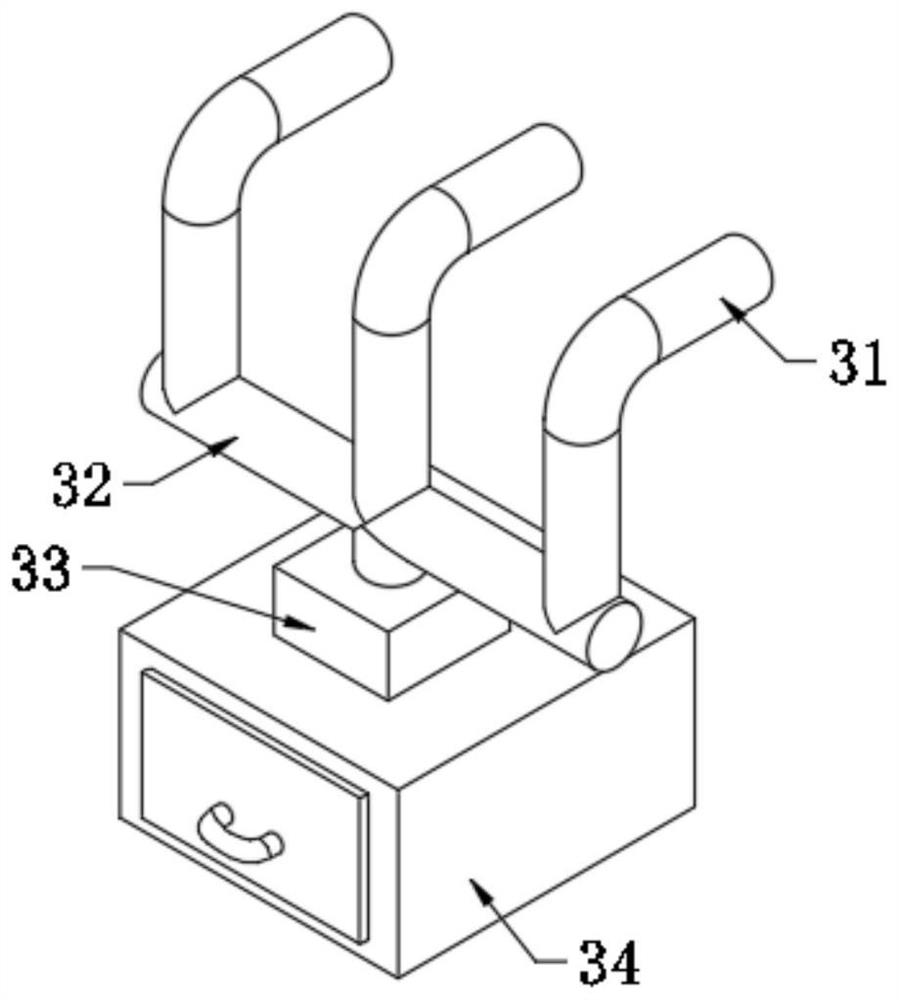

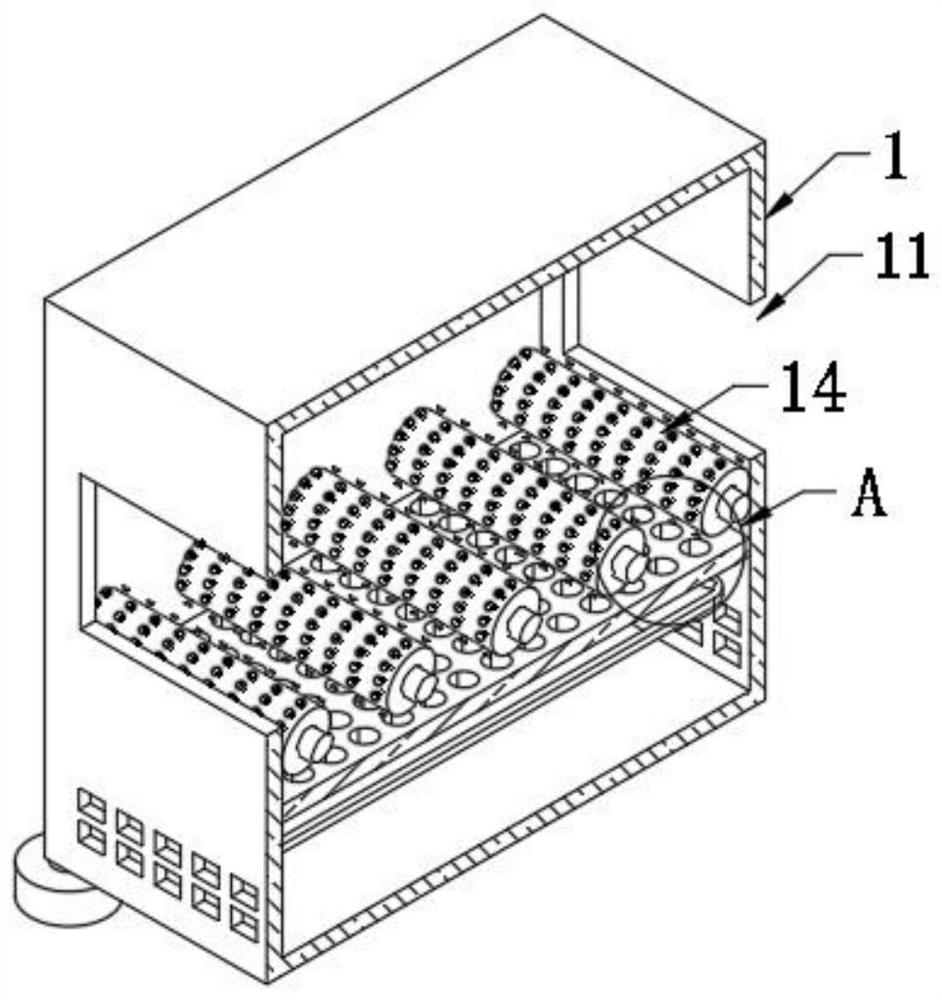

[0031] refer to Figure 1-8 In this embodiment, a high-efficiency and energy-saving rail-type lithium battery oven is proposed, which includes an oven body 1, and a passage port 11 is opened on both sides of the oven body 1, and a support mechanism 2 is fixedly installed on both sides of the oven body 1, and the oven body One side of 1 is fixedly installed with a filter mechanism 3, and a plurality of linearly distributed power guide rollers 14 are installed in rotation in the oven body 1. The inner wall of the bottom of the oven is even, and the oven body 1 is fixedly equipped with a heating wire 12, which is located under a plurality of power guide rollers 14, and a plurality of ring-shaped self-priming mechanisms 15 are fixedly installed on the power guide roller 14.

[0032]When working, the lithium battery can be placed on the two round rollers 23 of the support mechanism 2 on the left when baking the lithium battery, and then the lithium battery is pushed into the oven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com