Double-area double-circulation flue gas carbon dioxide absorption tower and process

A technology of carbon dioxide and absorption towers, which is applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of increasing equipment footprint, reducing equipment investment costs, reducing the height of absorption towers, etc., to achieve height reduction, Achieve automatic control and safe operation, and reduce energy consumption in the regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

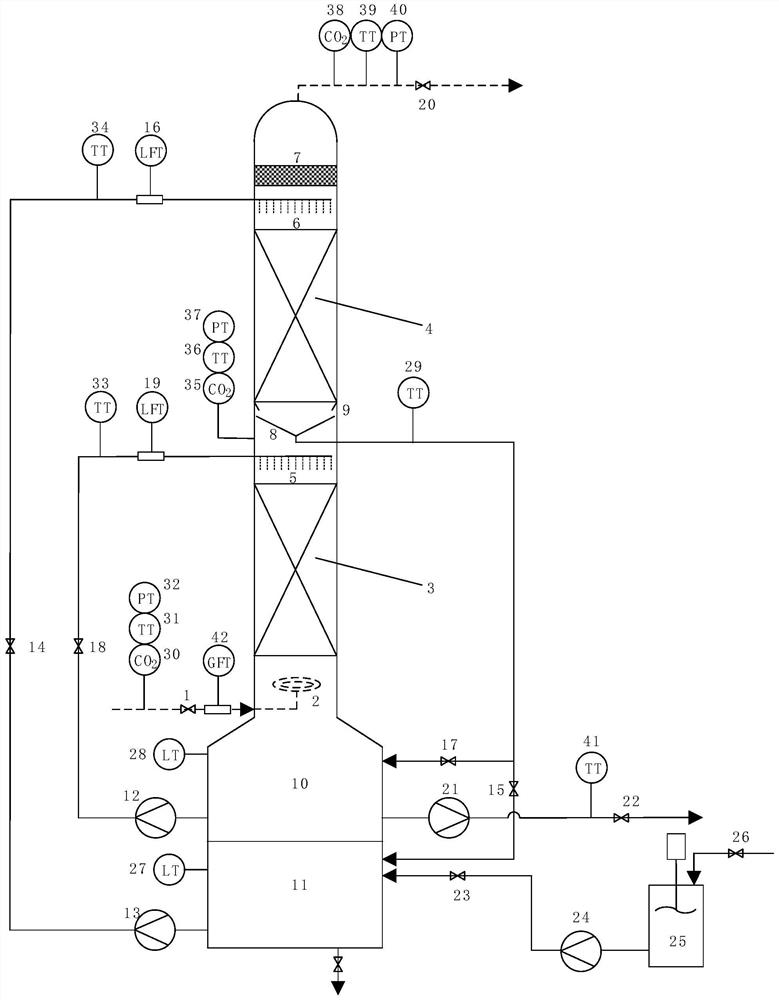

[0038] Embodiment 1 of the present application provides a dual-zone double-cycle flue gas carbon dioxide absorption tower, including a raw flue gas inlet flow regulating valve 1, a raw flue gas distributor 2, a lower absorption packing layer 3, an upper absorption packing layer 4, and a lower spraying layer Device 5, upper layer spray device 6, absorption tower demister 7, upper layer absorption liquid collector 8, upper layer filler anti-wall flow circle 9, tower kettle one 10, tower kettle two 11, lower layer liquid supply pump 12, upper layer liquid supply pump 13. The flow regulating valve of the upper layer liquid supply pump 14, the second valve of the upper layer absorption liquid return tower kettle 15, the upper layer absorption liquid flowmeter 16, the upper layer absorption liquid return tower kettle one valve 17, the lower layer liquid supply pump flow regulating valve 18, the lower layer absorption liquid Flow meter 19, clean flue gas discharge valve 20, absorption...

Embodiment 2

[0050] Embodiment 2 of the present application provides a process for a double-zone double-circulation flue gas carbon dioxide absorption tower. The flue gas is introduced into the absorption tower through the original flue gas inlet flow regulating valve 1 and the original flue gas distributor 2, and then passes through the lower absorption packing layer 3, The upper absorption packing layer 4 and the absorption tower demister 7 are discharged from the absorption tower; after the absorption liquid is prepared in the absorption liquid preparation tank 25, it is pumped into the tower kettle two 11 through the absorption liquid replenishment pump 24, and the absorption liquid in the tower kettle two 11 is The upper-layer liquid supply pump 13 transports it to the upper-layer absorption tower, and sprays it evenly on the upper absorption packing layer 4 through the upper-layer spray device 6. After the reaction is completed, it flows back from the upper-layer absorption liquid coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com