Detection equipment for automatic lathe and using method of detection equipment

A detection equipment and automatic lathe technology, applied in the field of lathe detection, can solve the problems of inability to adjust and move the device, inability to adjust the detection mechanism, single use structure, etc., and achieve the effects of increasing the detection range, convenient lighting, and excellent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

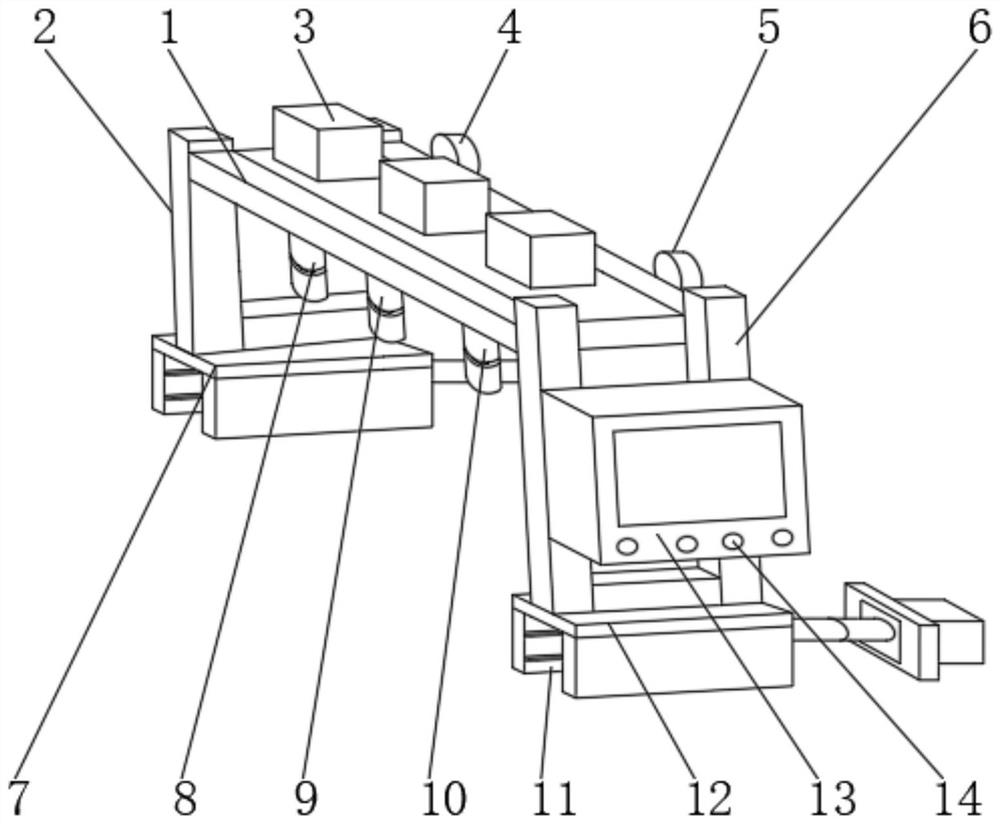

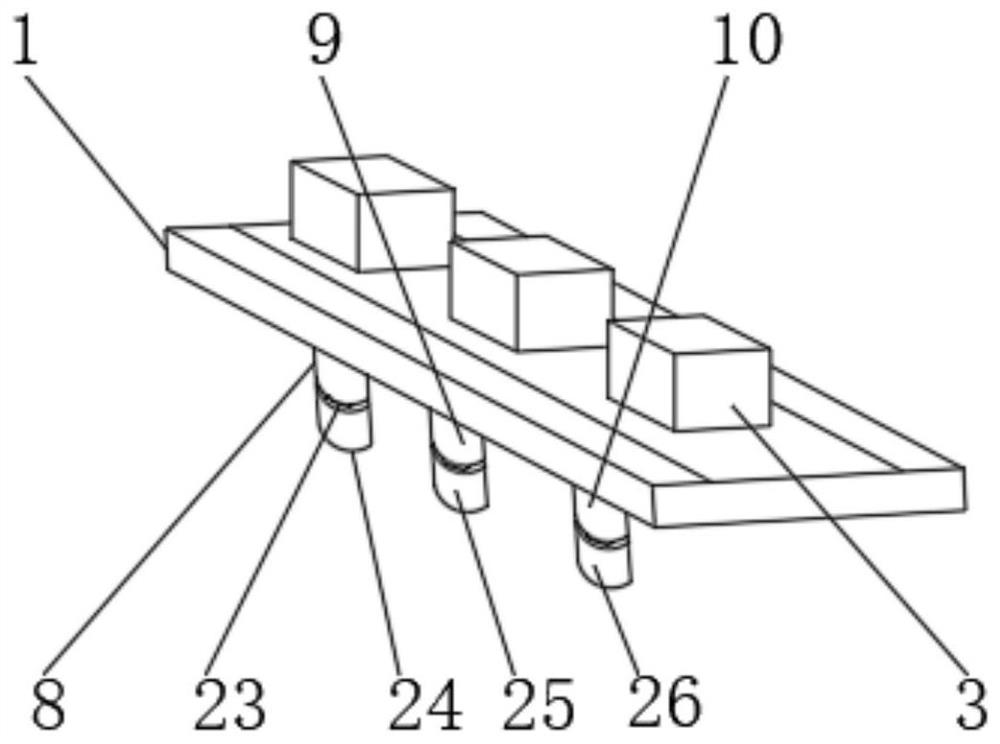

[0032] like figure 1 , 3 Shown, an automatic lathe with the sensing device, the device comprising a top plate, the top plate 1 is fixed to one end of the device is connected to mounting post One 2, apparatus 1 is fixed to the top plate and the other end connected to the mounting posts 6 II, One mounting post 2 One lower end fixedly attached to the positioning holder 7, the lower end of the mounting post II 6 II fixedly mounted positioning abutment 12, on the 2nd column 6 is mounted is attached to the outside of the control box 13, outer box 13 is attached to a control housing 14 to control , the upper end of the top plate unit 1 is mounted a drive mechanism 3, the lower end of the top plate unit 1 mounted One mounting rod 8, II and III mounting posts 9 the mounting bar 10.

[0033] One mounting bar 8 is attached to the lower end of the temperature monitoring sensor 24, the lower end of the rod 9 II mounting position mounted condition monitoring probe 25, the lower end of the mount...

Embodiment 2

[0040] On the basis of the first example, if figure 1 , 2 , 4, with the sensing device for an automatic lathe, comprising a roof apparatus 1, the top end of the apparatus 1 is fixed to mounting post 2 is connected to One, the other end of the top plate 1 has a connecting device 6 II mounting posts, the mounting posts One 2 with a lower end fixedly mounted One positioning abutment 7, the lower end of the mounting post II 6 II fixedly mounted positioning abutment 12, on the 2nd column 6 is mounted is attached to the outside of the control box 13, the outer control box 13 is mounted a control Block 14, the upper end of the top plate unit 1 is mounted a drive mechanism 3, the lower end of the top plate unit 1 mounted One mounting rod 8, II and III mounting posts 9 the mounting bar 10.

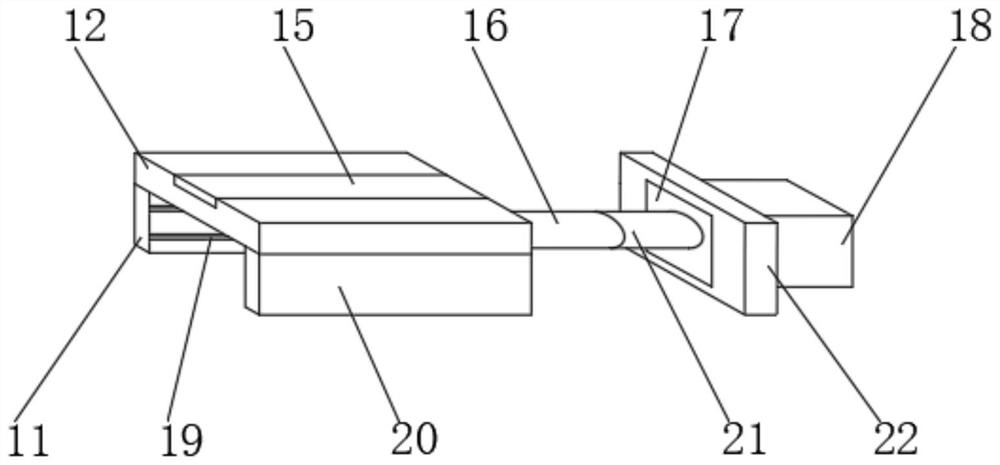

[0041] II positioning the positioning plate 15 is attached to mounting, II positioning abutment 12 is attached to the lower end of the slide plate 11 and II One slide plate 20, the slide plate 11 defin...

Embodiment 3

[0049] On the basis of the second embodiment, as figure 1 , 5 , 6, an automatic lathe with the sensing device, the device comprising a top plate 1, the top end of the apparatus 1 is fixed to mounting post 2 is connected to One, the other end of the top plate 1 has a connecting device 6 II mounting posts, the mounting posts One 2 with a lower end fixedly mounted One positioning abutment 7, the lower end of the mounting post II 6 II fixedly mounted positioning abutment 12, on the 2nd column 6 is mounted is attached to the outside of the control box 13, the outer control box 13 is mounted a control Block 14, the upper end of the top plate unit 1 is mounted a drive mechanism 3, the lower end of the top plate unit 1 mounted One mounting rod 8, II and III mounting posts 9 the mounting bar 10.

[0050] The control box 13 includes a central management module, a control module, power module, a temperature monitoring module, the position of the state monitoring module, working status monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com