Steel-aluminum structure fused four-degree-of-freedom economical active compensation gangway ladder

A technology of active compensation and degrees of freedom, applied in ships, cargo handling equipment, passenger handling equipment, etc., can solve problems such as difficulty in meeting accuracy requirements, poor application safety, and difficulty in post-maintenance maintenance, to improve accuracy and measurement error, and improve economy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

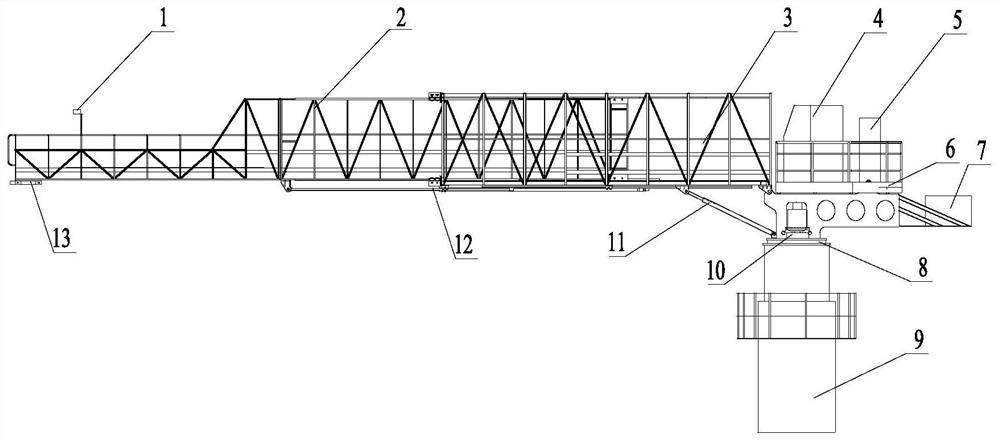

[0020] Such as figure 1 The shown one kind of steel-aluminum structure fusion four-degree-of-freedom economical active compensation gangway includes a movable ladder 2 at the front end of the telescopic structure and a fixed ladder 3 at the rear end; the fixed ladder 3 is installed on the operating platform 4, and the operating platform 4 It is installed on the turntable 6, and the turntable 6 is installed on the single-degree-of-freedom support mechanism 9.

Embodiment 2

[0022] Based on Embodiment 1, a telescopic oil cylinder 12 is installed between the movable ladder 2 and the fixed ladder 3 .

Embodiment 3

[0024] Based on Embodiment 1, a pitch cylinder 11 is installed between the fixed ladder 3 and the single-degree-of-freedom support mechanism 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com