Cylindrical wood formwork stacking device for building construction

A technology for building construction and wood formwork, applied in packaging, bundling machinery parts and other directions, can solve problems such as low efficiency, space error between formwork and formwork, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

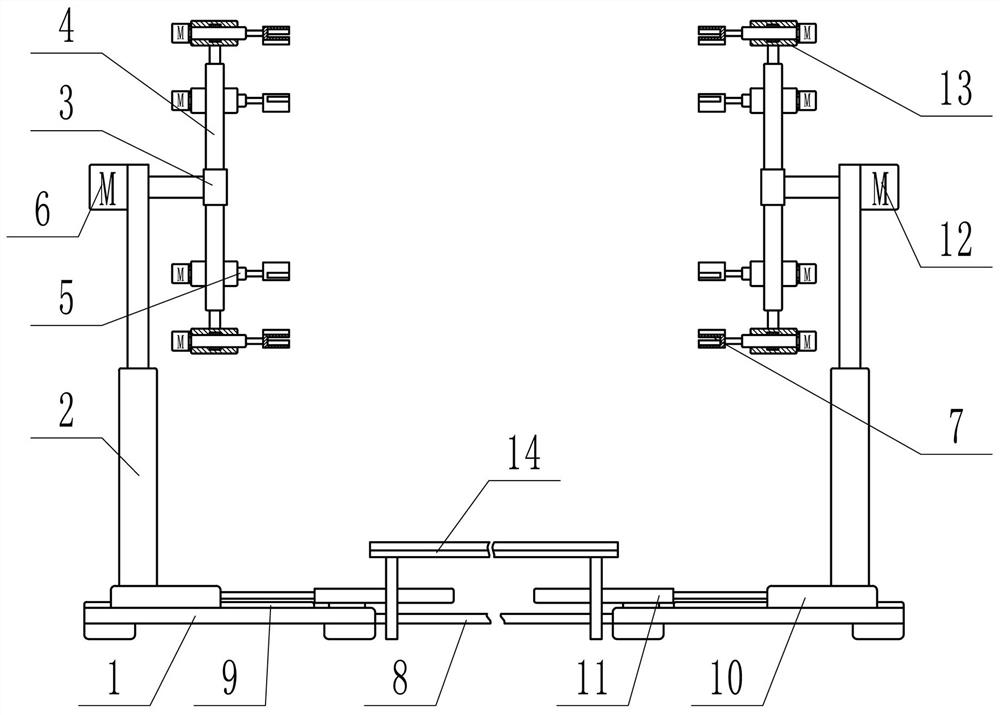

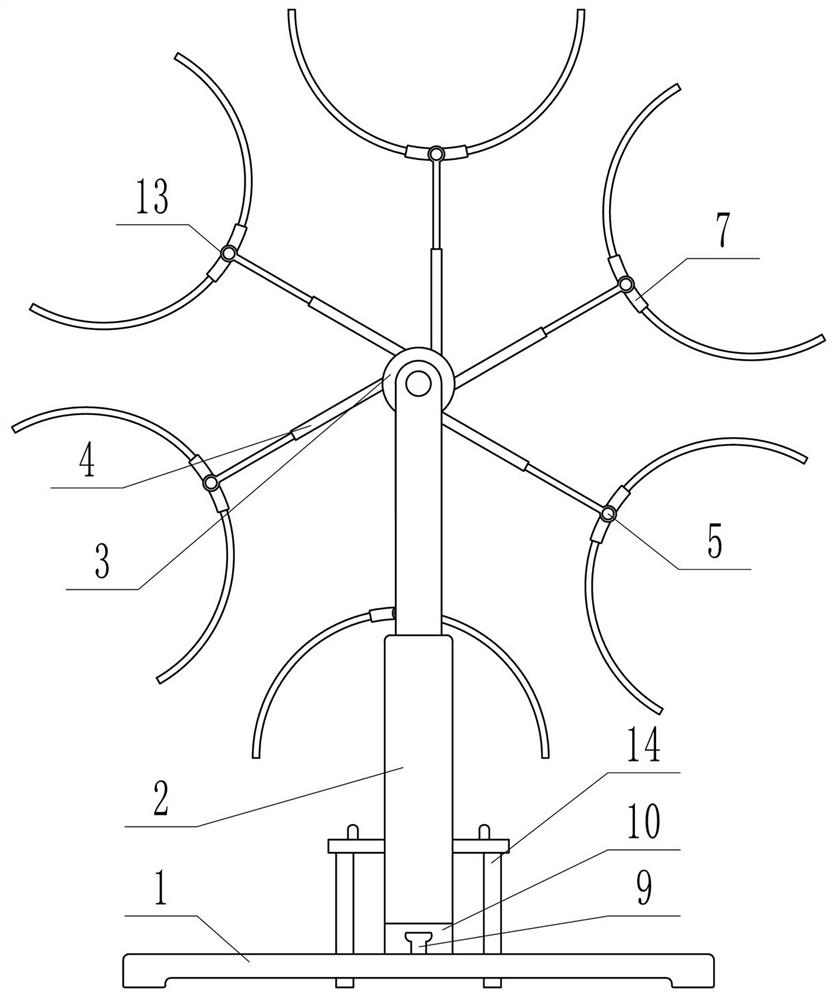

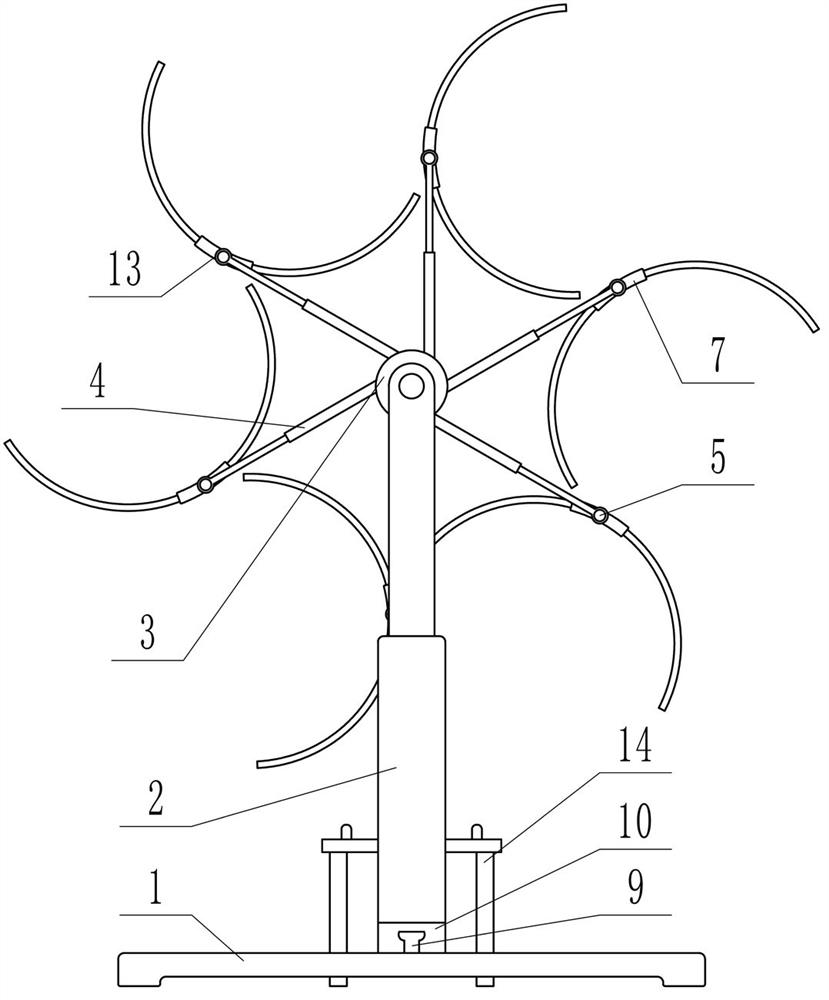

[0022] Depend on Figure 1 to Figure 6 It can be seen that the present invention includes two bases 1 on the left and right, and a first electric cylinder 2 that is vertical and movable left and right is slidably installed on each base 1, and a disc 3 is installed on the upper end of the first electric cylinder 2 in rotation. The axis 3 is perpendicular to the axis of the first electric cylinder 2 and the axes of the left and right disks 3 coincide. There are multiple second electric cylinders 4 evenly distributed on the disk 3 along its circumferential direction, and the multiple second electric cylinders 4 can be synchronized Control expansion and contraction, the axis of the second electric cylinder 4 is tangent to the coaxial circle of the disc 3, and the extension end of each second electric cylinder 4 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com