Asphalt pavement rut calculation method considering load frequency

A technology of asphalt pavement and calculation method, which is applied in complex mathematical operations, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problem of not considering the influence of vehicle speed on road rutting, etc., and achieve accurate rutting deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

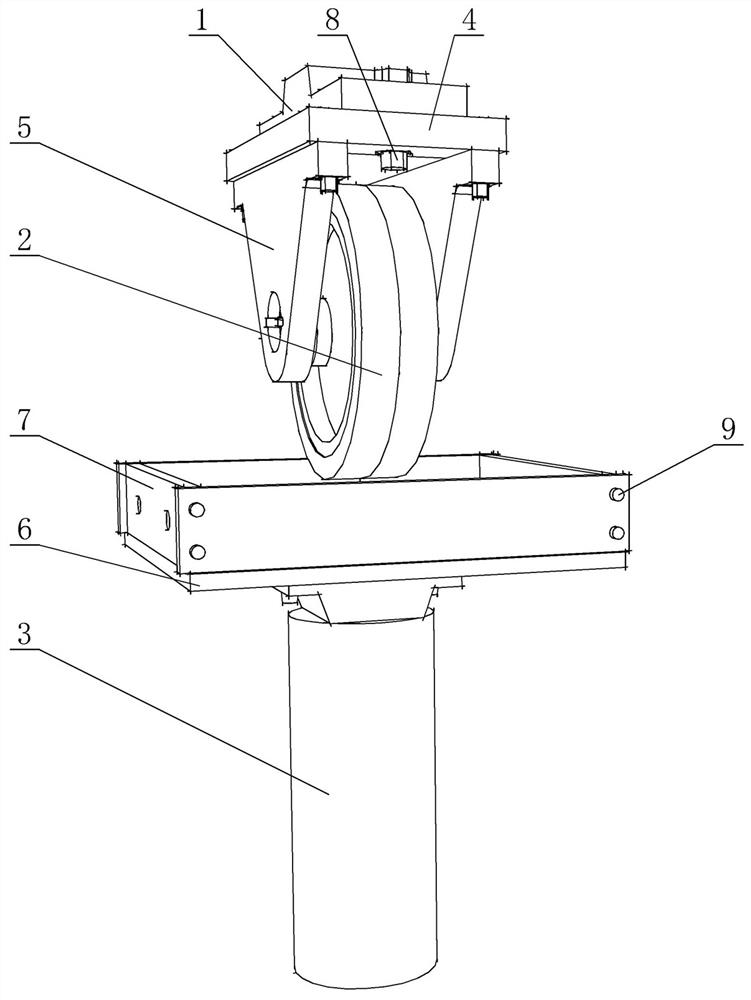

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0040] The calculation method for asphalt pavement rutting considering the load frequency of the present invention adopts the following calculation formula to calculate the permanent deformation of the asphalt pavement rutting:

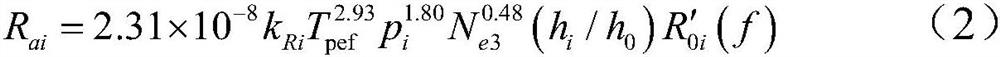

[0041]

[0042]

[0043] Where: R a —Permanent deformation of asphalt mixture layer, unit mm;

[0044] R ai —the amount of permanent deformation of the i-th layer, in mm;

[0045] n—number of layers;

[0046] T pef —Equivalent temperature of permanent deformation of asphalt mixture layer, unit ℃;

[0047] p i —Vertical compressive stress on the top surface of the i-th layer of the asphalt mixture layer, unit MPa;

[0048] N e3 - The cumulative action times of the equivalent design axle load on the design lane during the design service life or the period from the opening to traffic to the first rutting repair;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com