Pressure balance system

A technology of balance and pressure, which is applied in the measurement of fluid pressure, the measurement of pressure difference between multiple valves, and the measurement of fluid pressure through electromagnetic components, etc. It can solve the problems of affecting the accuracy of the sensor, the large volume of the pressure stabilizing chamber, and the consumption of silicone oil. , to achieve the effect of reducing unbalance, improving accuracy and reducing the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

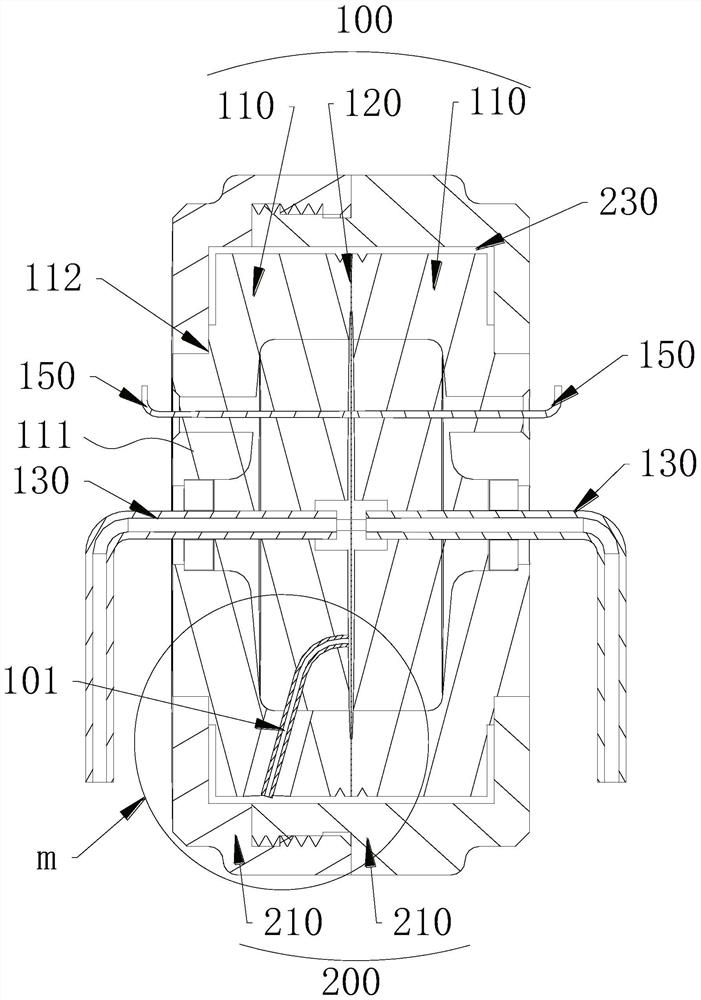

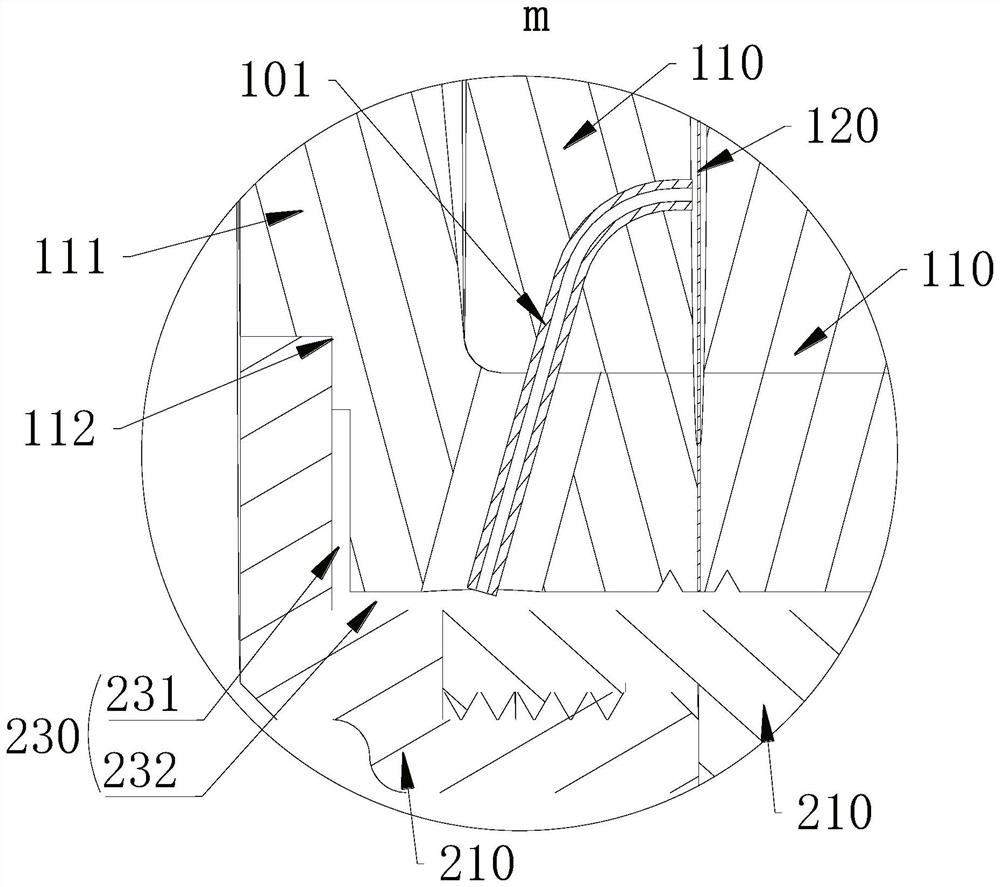

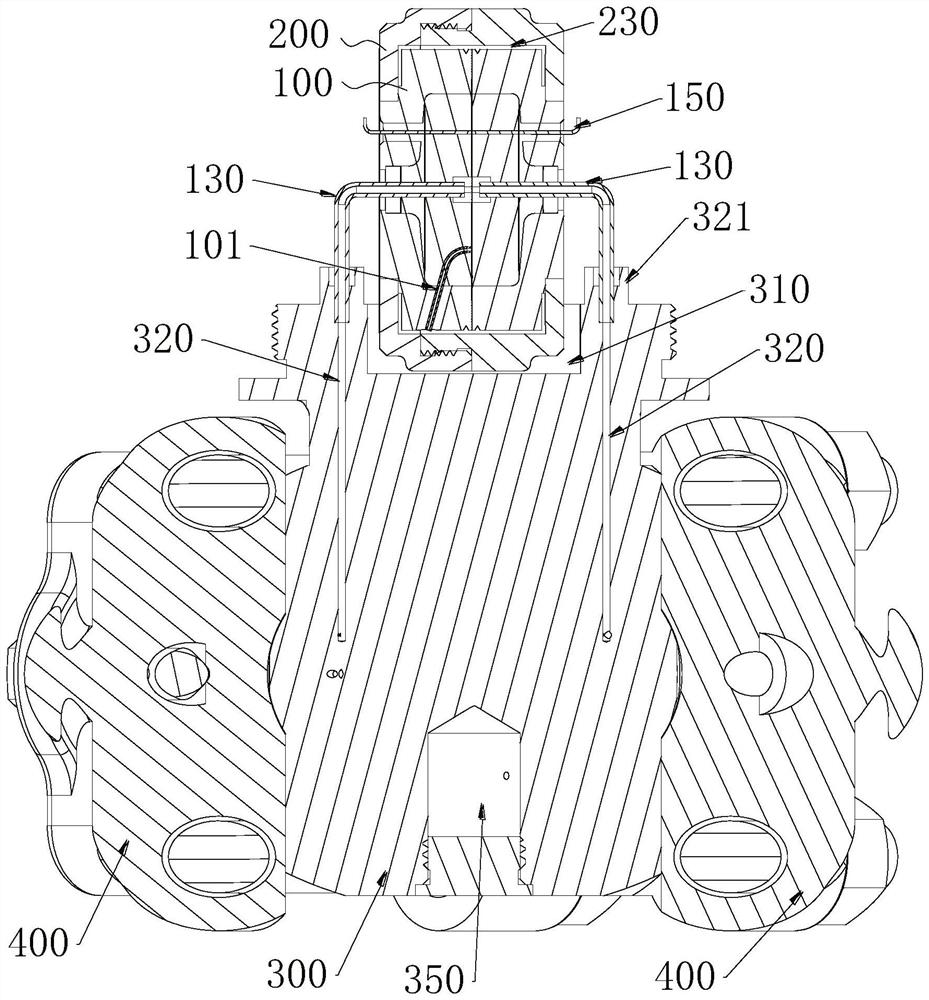

[0047] like Figure 1~3 As shown, a pressure balance system includes a diaphragm pressure sensor 100. The diaphragm pressure sensor 100 includes two diaphragm seats 110 facing oppositely, and a measuring diaphragm is interposed between the two diaphragm seats 110. The two diaphragm seats 110 are welded to the edge of the measuring diaphragm 120, and the measuring diaphragm 120 and the two diaphragm seats 110 respectively enclose a closed pressure transmission cavity. The outer cover of the diaphragm pressure sensor 100 is provided with a closed voltage stabilizing box 200, and there is a closed cavity between the inner wall of the stabilizing box 200 and the outer wall of the diaphragm pressure sensor 100, and the cavity surrounds the The outer wall of the diaphragm pressure sensor 100 is described above, and the cavity forms a pressure-stabilizing cavity 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com