Automatic welding machine and welding method for steel structural parts

A technology for automatic welding machines and steel structural parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy danger, high labor intensity, heavy weight, etc., to reduce labor intensity, The effect of improving efficiency and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] For the convenience of description, in the following description, the direction of the steel structure 2 is "longitudinal", and the direction perpendicular to the steel structure 2 in the horizontal plane is "transverse".

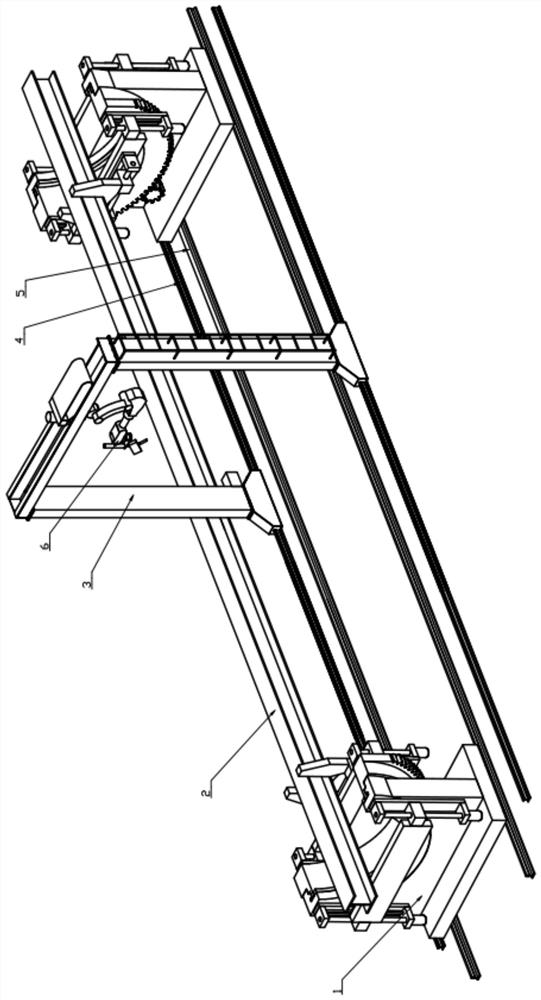

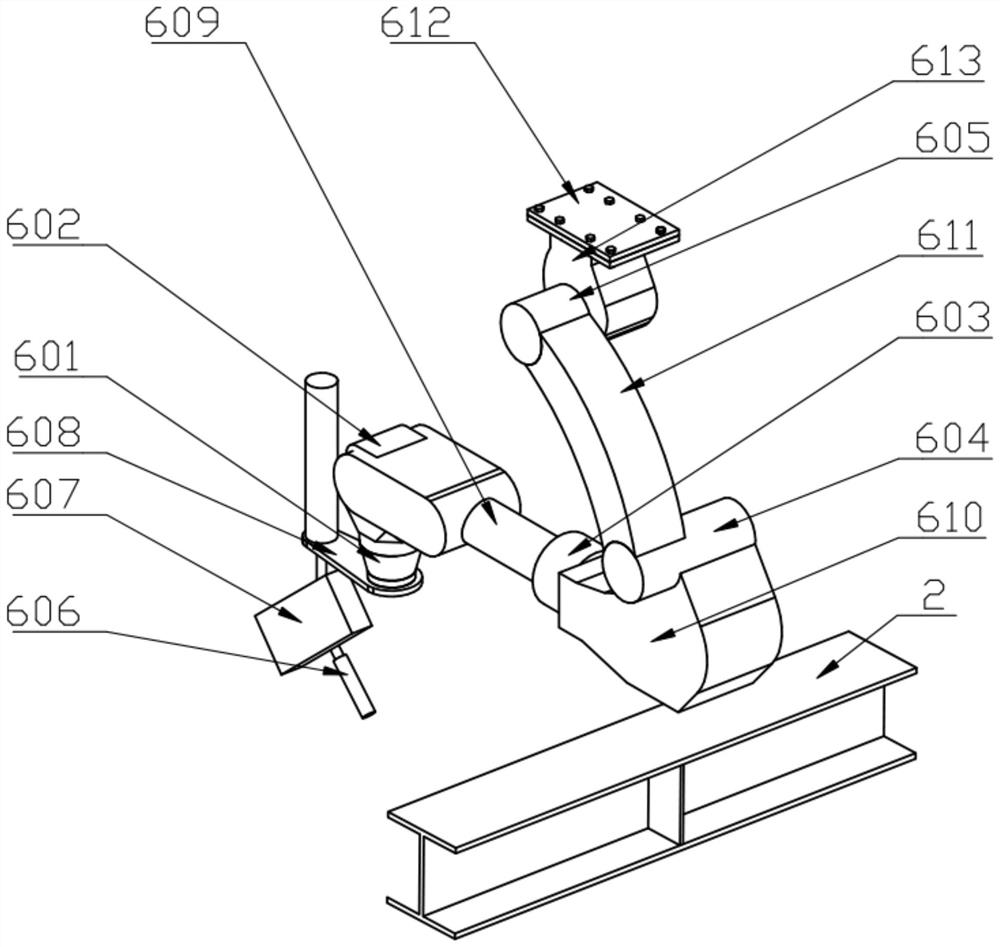

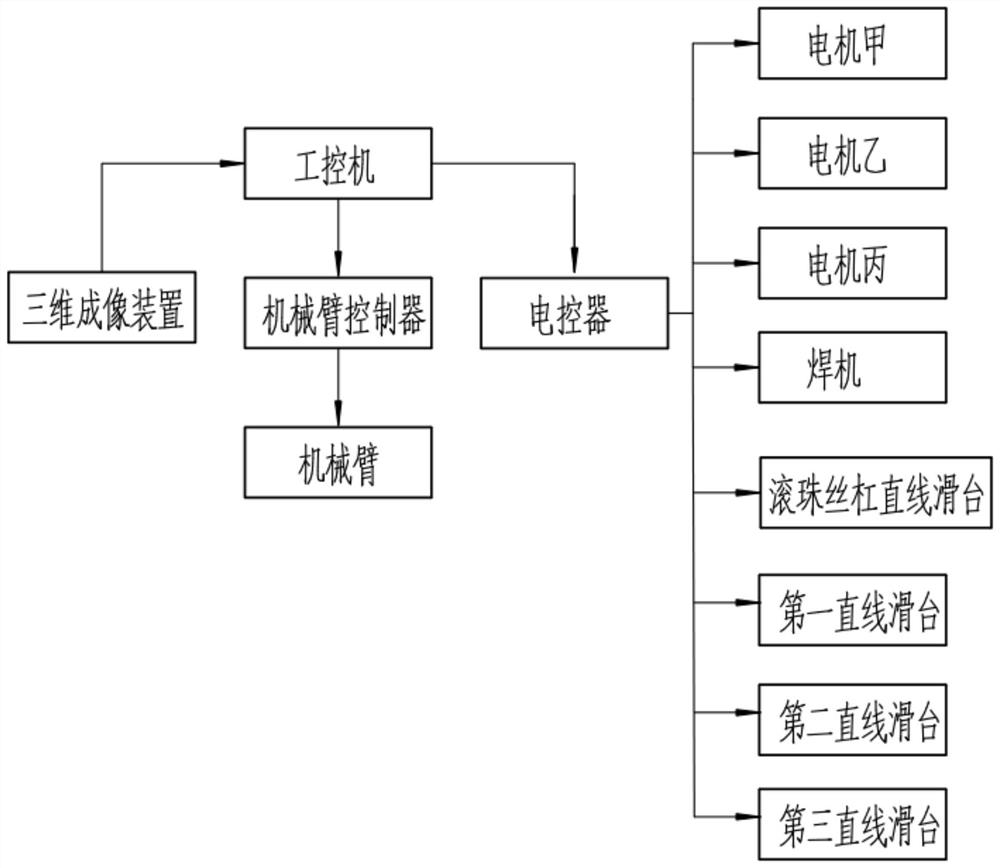

[0041] Such as figure 1 and figure 2 As shown, an automatic welding machine for steel structures includes a gantry 3 that straddles the steel structure 2 to be welded and can move longitudinally along the steel structure 2 and a welding arm 6 arranged in the gantry 3 . Described welding arm comprises mechanical arm, the mounting plate 612 that is fixedly arranged on the upper end of mechanical arm, is arranged on the traversing device that is used to drive mounting plate 612 to move laterally on the top of gantry frame 3, the connecting plate 608 that is fixedly arranged on the lower end of mechanical arm, fixes The welding torch 606 arranged on the connection plate 608 and the three-dimensional imaging device arranged beside the welding torch 606 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com