Controllable inductance technology used for improving arc welding power source characteristics

An arc welding power source and inductance technology, which is applied in the field of controllable inductance technology and thyristor arc welding power source, can solve the problems that the response speed of the electronic reactor is very high, and the ordinary thyristor arc welding power source cannot be fully applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

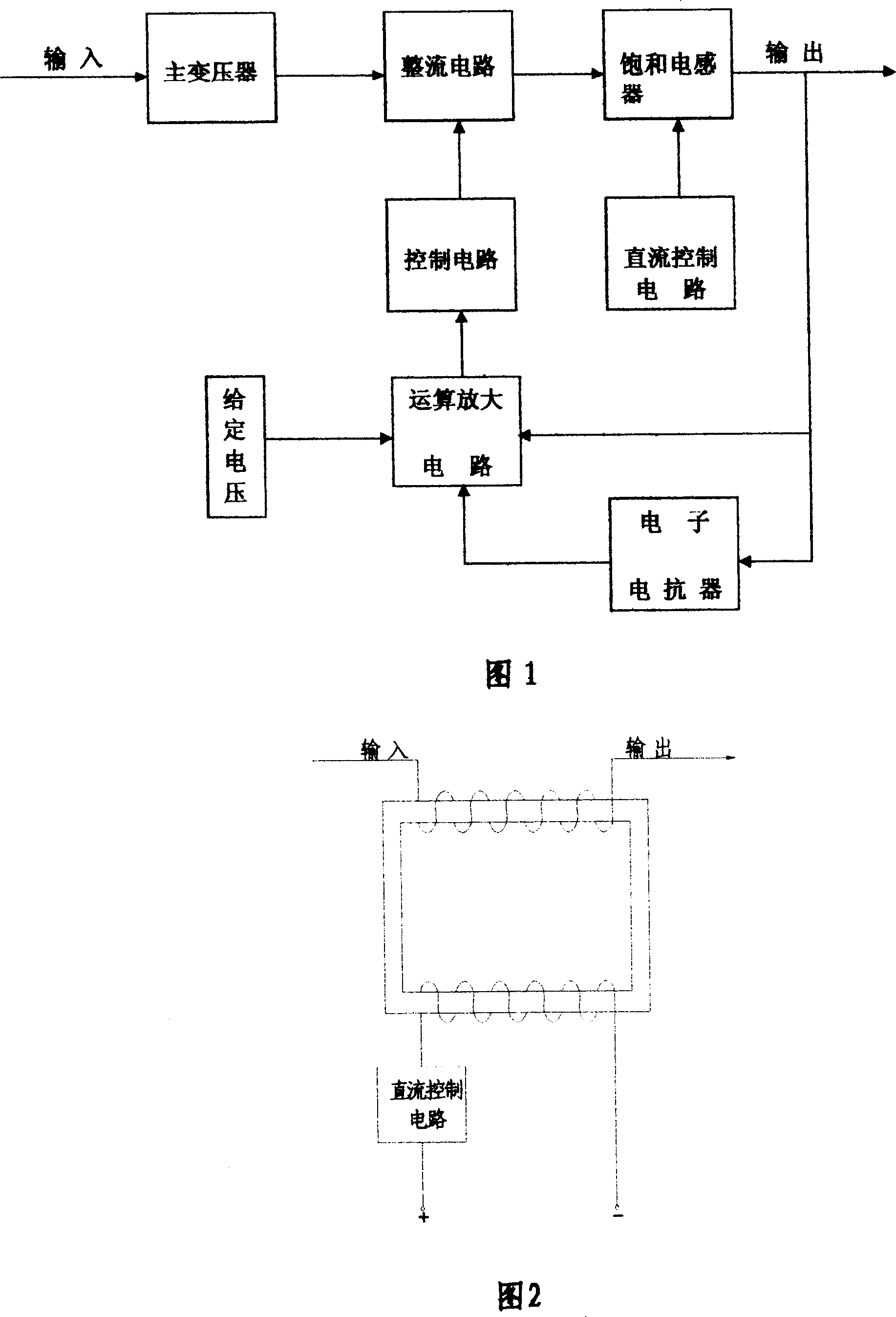

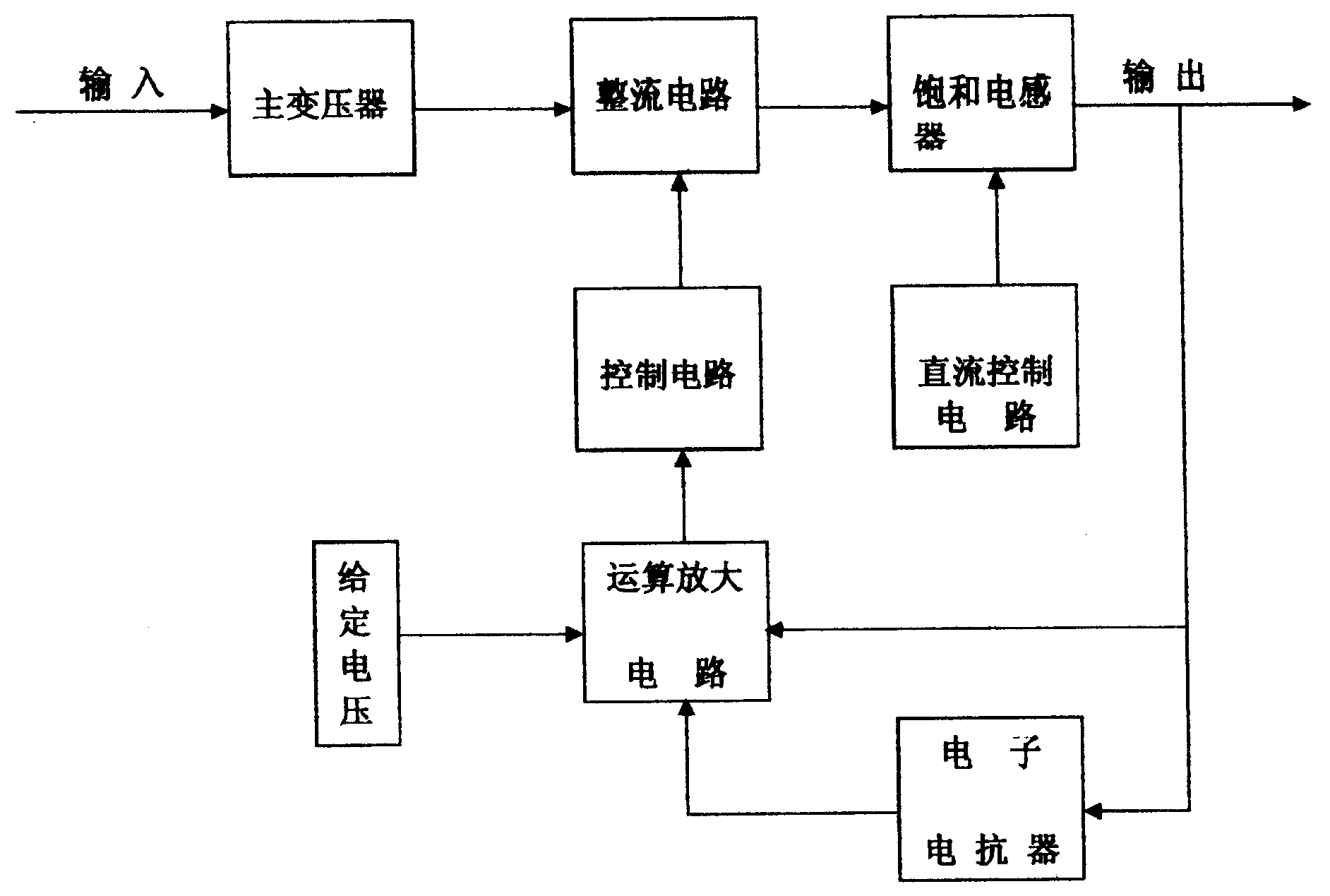

[0009] Embodiment 1, as can be seen from FIG. 1, the rectifier circuit of the present invention may be a thyristor rectifier circuit or an inverter circuit. After the AC input is stepped down by the main transformer and rectified by the rectifier circuit, it becomes a DC pulsating waveform, which is then output through a saturated inductor. The electronic reactor samples the output, and its signal is sent to the control circuit through operational amplification. In the ordinary thyristor arc welding power supply, the control circuit changes the conduction angle of the thyristor, and the inverter changes the switching time and frequency of high-power electronic components, thereby Realize the control of rectification output. When the electronic reactor monitors that the welding current is greater than the given value, it is judged that the welding circuit has been short-circuited. At this time, the electronic reactor outputs a negative signal, and the output of the rectifier cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com