A vibration damping device for a capacitor processing machine tool

A capacitor processing and vibration damping device technology is applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc. The effect of flexibility, reduced amplitude and stable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

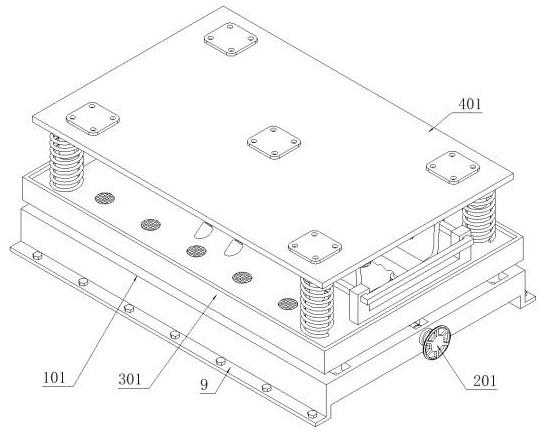

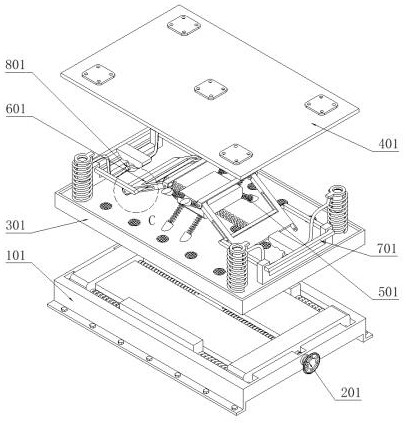

[0081] as attached figure 1 to attach Figure 17 Shown:

[0082] The invention provides a vibration damping device for a capacitor processing machine tool, which includes a support device 1; a support device 1, and mounting plates 9 are fixedly connected to both sides of the support device 1; A collection connection part 3 is installed, and a machine tool installation part 4 is fixedly connected to the collection connection part 3; a driving support part 6 is installed on the top of the machine tool installation part 4; two pressurizing devices 7 are fixedly connected to the top of the collection connection part 3, and the two The structures on the two pressurizing devices 7 are the same; two lubricating and cooling parts 8 are installed on the collecting connection part 3, and the structures on the two lubricating and cooling parts 8 are the same; The screw rod 201 is rotated and connected to the support base 101; and the opposite screw rod 201 is provided with a reverse th...

Embodiment 2

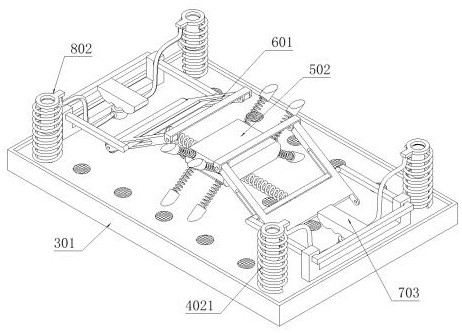

[0086] as attached Figure 12 , 13As shown, the stabilizing device 5 includes: tightening extension springs 501, eight tightening extension springs 501 are provided; four tightening extension springs 501 on the upper side are fixedly connected to the bottom of the machine tool mounting plate 401, and four tightening extension springs on the lower side 501 is fixedly connected on the collection box 301; counterweight 502, and counterweight 502 is fixedly connected on eight tension springs 501; the driving support part 6 comprises: driving bracket 601, and driving bracket 601 is provided with two; The drive bracket 601 is connected to the bottom of the machine tool mounting plate 401 through the bracket rotation; the middle part supports the extension spring 602, and the middle part supports the extension spring 602 and is fixedly connected between the two drive brackets 601; the drive support part 6 also includes: a roller 603, the roller 603 is provided with Two, two rollers ...

Embodiment 3

[0088] On the basis of the first embodiment, other structures remain unchanged. This embodiment provides another structural form of the pressure applying block 703, which can solve the problem that the long-term use of the pressure applying block 703 causes greater wear and tear on the pressurizing pump head 801. The device 7 includes: a pressurized driving frame 701, which is slidably connected to the linkage groove 604; a sliding bracket 702, which is fixedly connected to the collection box 301, and the sliding bracket 702 is slidably connected to a pressurized driving frame 701; the pressing block 703, the pressing block 703 is fixedly connected on the pressurizing drive frame 701; the wear-resistant rubber pad is fixedly connected at the bottom of the pressing block 703, which can effectively reduce the pressure applying block 703 on the pressurizing pump head 801 Wear and tear, better protect the pressurized pump head 801; two drive brackets 601 drive the pressurized drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com