Esterification reaction esterification kettle for producing DOP

A technology of esterification reaction and esterification kettle, which is applied in the field of DOP esterification reaction and esterification kettle in 7528, which can solve the problems affecting the stability of support feet, rollover, and reaction kettle shaking, so as to correct the angle and prevent shaking The effect of the angle is too large and the shaking range is moderate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] Example 1

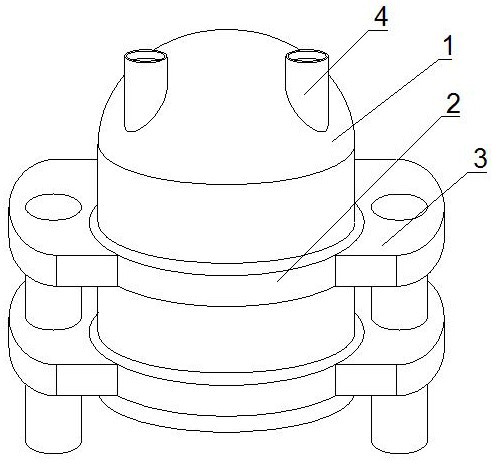

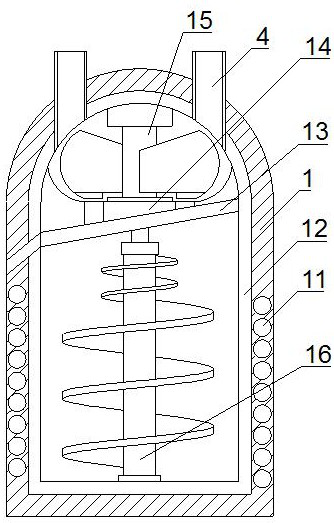

[0038] like Figure 1-8 , The present invention provides a method of producing DOP esterification esterification reactor, comprises a reaction vessel 1 vinegar, trap 2 is rotated, the supporting leg 3 and the buffer 4 into the cylinder, the outer surface of the reaction vessel 1 is connected to the activities for vinegar there trap 2 is rotated, rotation of the outer snare 2 is fixedly connected with a support surface of the buffer legs 3, the top of the reaction vessel 1 is provided with a vinegar feeder 4.

[0039] In the present embodiment, by the feeder 4 to the interior of the reaction vessel 1 was poured vinegar materials and additives, the reaction with the rotation of the two pairs of vinegar trap vessel 1 is rotated, to increase the flow of liquid inside, and then through the supporting leg 3 buffer shaking autoclave for reflecting a buffering vinegar.

Example Embodiment

[0040] Example 2

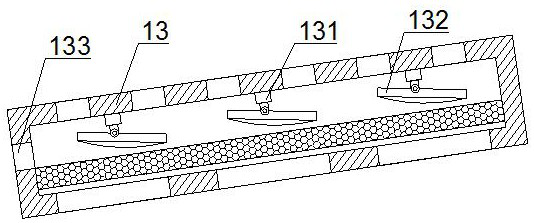

[0041] like Figure 1-8 As shown, in the basis of the first embodiment, the present invention provides a technical solution: preferably, the reaction acelline 1 includes a filter plate 13, and an over-water hole is opened on the outer surface of the filter plate 13, and the filter plate 13 is at top. The inner wall surface is fixedly connected to the pusher 131, and the rotary ball is fixed to the output of the pusher 131, and the outer surface of the rotary ball is fixed to the outer surface of the rotary ball is fixed, and the filter plate is fixed on the inner wall surface of the filter plate 13. The diameter diameter of the cross surface on the lower surface of the filter plate 13 is longer than the overwater hole on the top surface, and there is a guide 133 on the outer surface of the filter plate 13.

[0042] In the present embodiment, the top DOP vinegar is permeated by the overdrophone on the outer surface of the filter plate 13, and the sagging of the roll...

Example Embodiment

[0043] Example 3

[0044] like Figure 1-8 As shown in the basis of the first embodiment, the present invention provides a technical solution: preferably, the support buffer leg 3 includes a base 31, the outer surface of the base 31 has a U-shaped casing 32, base 31 The upper surface is fixed to the end surface of the buffer spring 33, and the buffer spring 33 is fixed on the inner surface of the U-shaped casing 32, and the buffer spring 33 is uniformly distributed on the top surface of the base 31, the outer surface of the base 31. The upper surface of the fixed seat 34, the top surface of the fixed seat 34 is fixedly connected, and the outer surface of the Y-shaped fixed block is fixedly connected to the outer surface activity of the card contact plate is attached to the stationary seat. On the inner surface of 34, a half arc slide is provided on the top surface of the Y-type fixed block, and the outer surface of the half arc groove is fixedly connected, and the inner wall surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com