Weighing device, method and sensor and storage medium

A technology for weighing devices and storage media, applied in measuring devices, weighing equipment testing/calibration, weighing equipment using elastically deformable parts, etc., can solve problems such as weighing errors in weighing systems, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

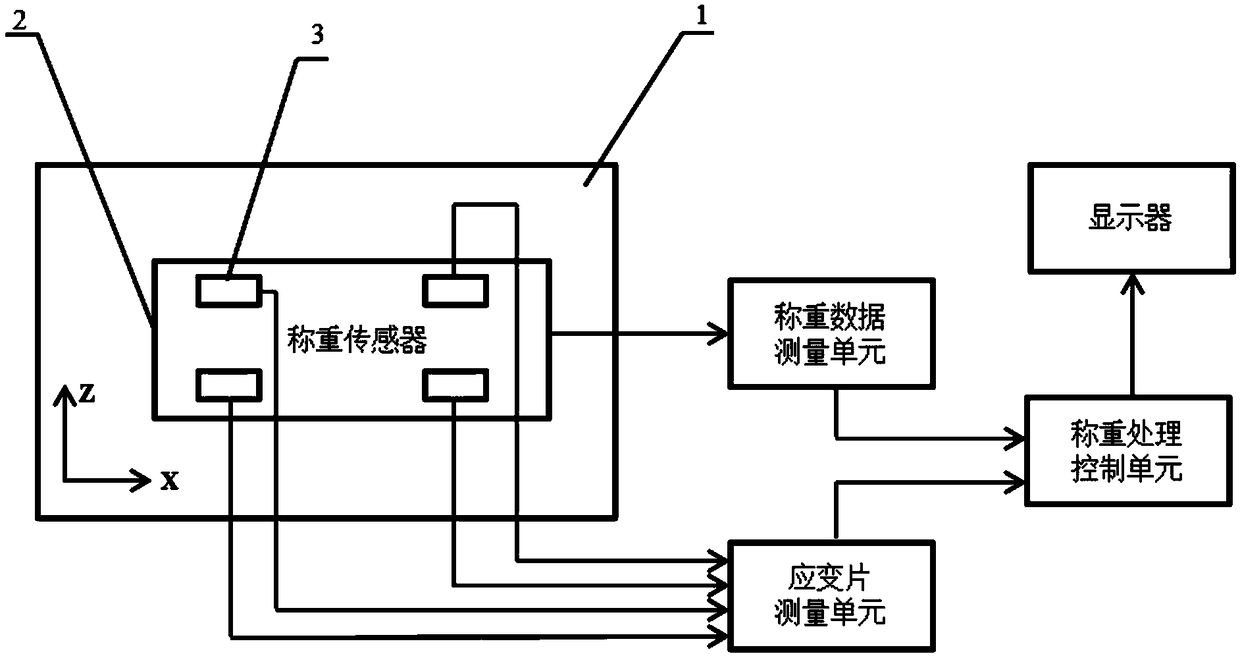

[0048] like figure 1 As shown, in this embodiment, the object to be measured is placed on the weighing platform 1 for weighing. The load cell 2 converts the weight of the measured object into the deformation of the elastic element, and then converts it into an electrical signal for identification and measurement, so as to obtain the weight of the measured object.

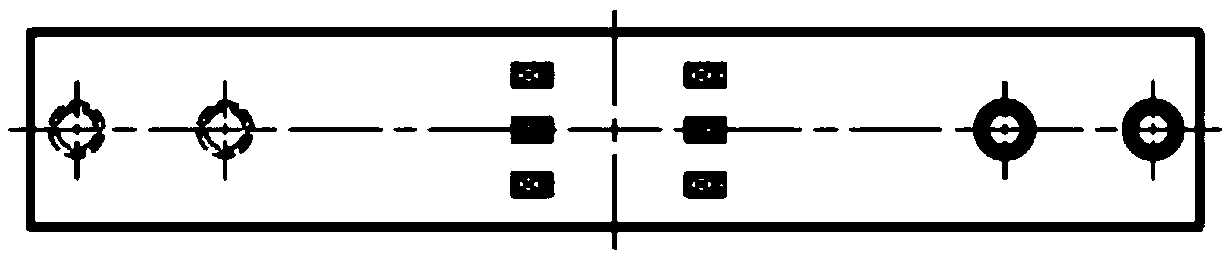

[0049] figure 2 It is a schematic diagram of the strain sensor of this embodiment, wherein the strain gauge 3 is pasted on the position-sensitive area of the elastic body of the load cell to measure the loading position of the measured object on the weighing platform. In this embodiment, a total of 4 strain gauges form a Wheatstone bridge Detect the deformation of the elastic body. In this embodiment, four strain gauges are attached to the position sensitive area of the surface of the beam near the weighing pan among the two parallel beams of the elastic body. The position sensitive area is the area where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com