A high-strength, high-toughness, impact-resistant, energy-absorbing al-mg-si alloy

An al-mg-si, high-strength and high-toughness technology, applied in the field of aluminum alloy materials, can solve the problems of unsuitability for wide application, complicated preparation process, high cost, etc., to improve the uniformity of channels and deformation, improve bending toughness and compression Crash performance, improve the effect of deformation behavior

Active Publication Date: 2022-07-22

NINGBO XINTAI MACHINERY

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the Chinese patent CN109504870B provides an aluminum alloy for lightweight automobile anti-collision beams, the synthesis reaction process and solidification process are regulated by direct melt reaction technology combined with ultrasonic magnetic coupling field technology, and a compound with uniform distribution of nanoparticles in situ is obtained. Materials, and then through hot extrusion forming and heat treatment, the preparation process is more complicated, difficult and costly, not suitable for wide application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-11

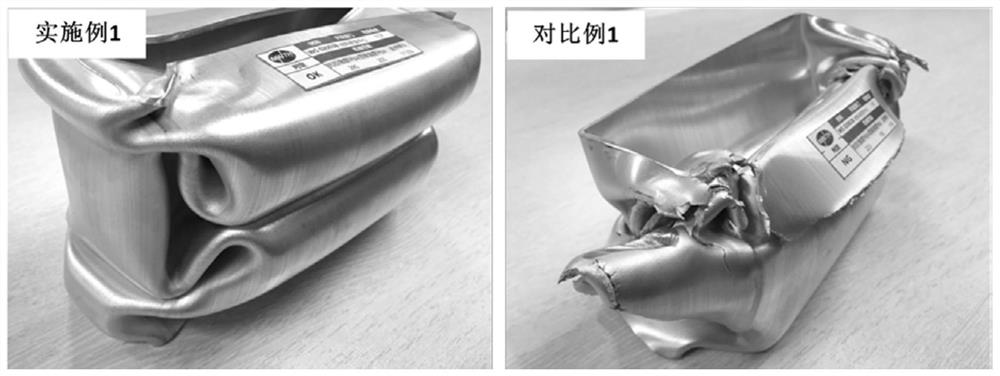

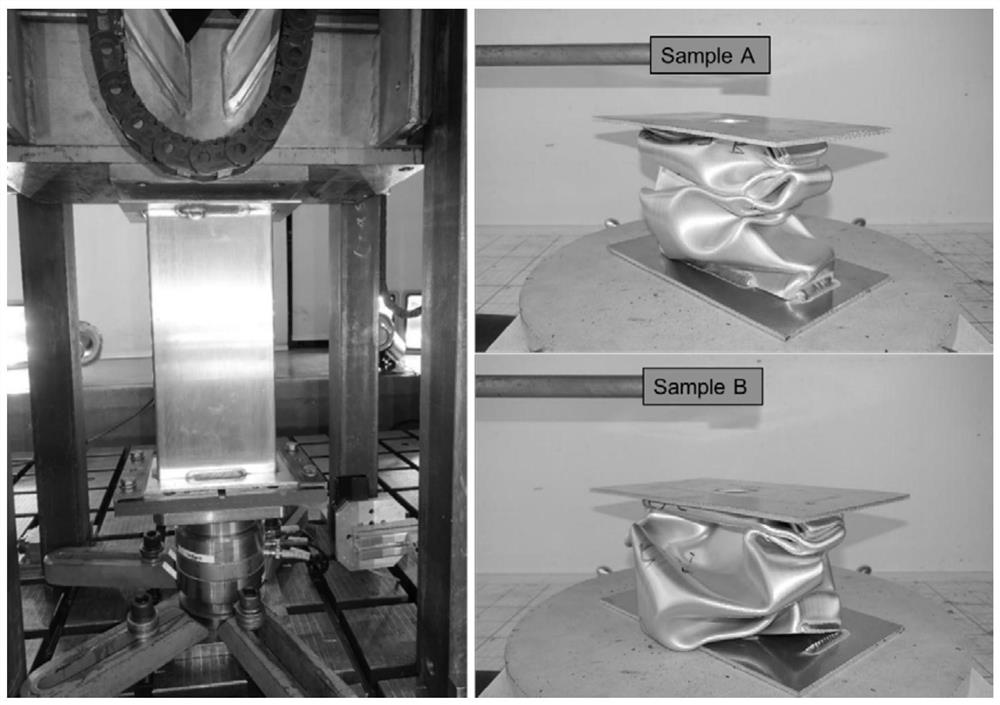

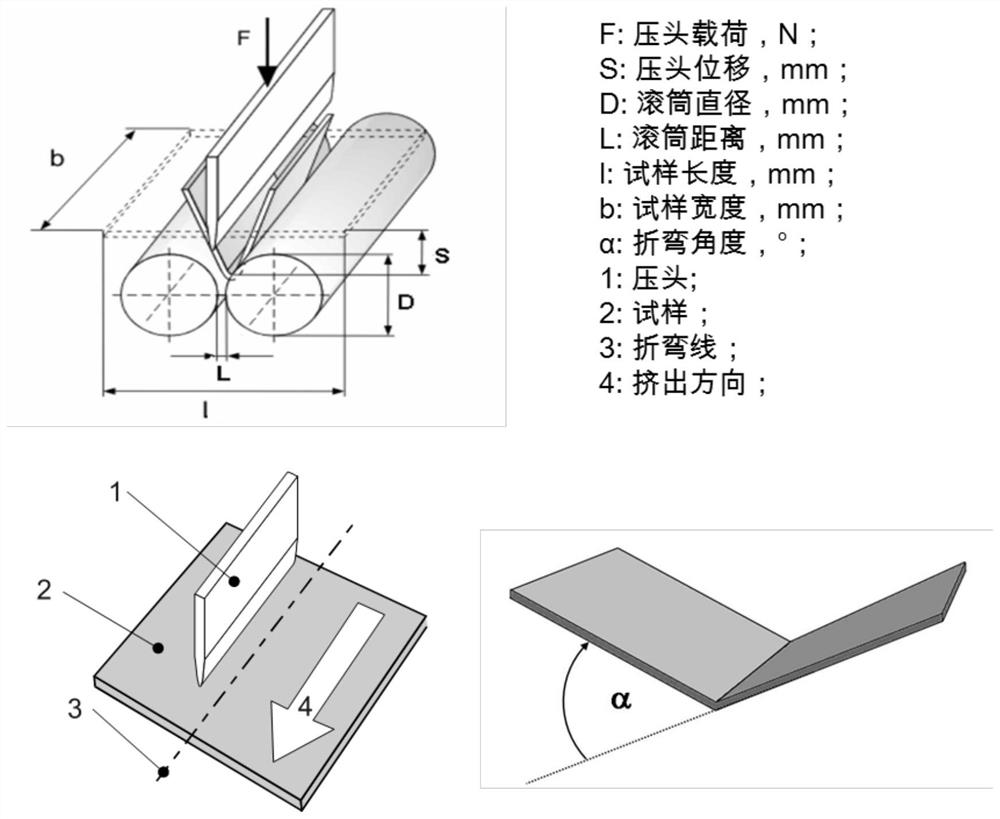

[0038] The components of the Al-Mg-Si alloys described in Examples 1-11 in Table 2 were smelted, semi-continuously cast into ingots, the ingots were cut and homogeneous, and then extruded and cooled by using corresponding cross-section molds. Finally, the extruded profiles were aged by T7 treatment.

Embodiment 12

[0040] The difference between Example 12 and Example 3 is only in the aging process, and the aging in Example 12 adopts T6 treatment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of aluminum alloy materials, in particular to a high-strength, high-toughness, impact-resistant, energy-absorbing Al-Mg-Si alloy. The Al-Mg-Si alloy of the present invention comprises Mg0.40-1.00%, Si0.50-0.90%, Mn≤0.60%, Cr≤0.30%, Fe≤0.25%, Al 96.8-99.1% in mass percentage, wherein, Si free =Si‑0.3×(Mn+Fe+Cr), Mg / Si free The mass ratio is 0.72‑1.40, and Mg+2Si free The mass percentage is 1.40% to 2.40%. The aluminum alloy provided by the invention not only has excellent conventional mechanical properties, but also has good bending toughness, and also has outstanding crushing and impact resistance energy absorption properties.

Description

technical field [0001] The invention belongs to the technical field of aluminum alloy materials, in particular to a high-strength, high-toughness, impact-resistant, energy-absorbing Al-Mg-Si alloy. Background technique [0002] With the continuous and rapid development of human economy and society, energy and environmental problems continue to emerge, and green, low-carbon, environmentally friendly and sustainable development has become the development direction of today's society. The fuel consumption of motor vehicles accounts for a considerable proportion of the total consumption of crude oil. The rapidly developing automobile industry not only poses a huge challenge to my country's oil supply, but also brings unprecedented pressure to the environment due to the emission of automobile exhaust. Energy saving and emission reduction is the key to the transformation and upgrading of the automobile industry, and lightweight is an important means to achieve energy saving and em...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/08C22C21/02C22C1/03C22F1/043C22F1/047C22F1/05

CPCC22C21/08C22C21/02C22C1/026C22C1/03C22F1/043C22F1/047C22F1/05

Inventor 蒋海春冉青荣孙玉玲刘灿威谷春明宋正成井佳明

Owner NINGBO XINTAI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com