Novel combined type slag salvaging device and using method thereof

A combined type and slag catcher technology, which is applied in the direction of earth cube drilling, sheet pile wall, wellbore/well parts, etc., can solve the problem of not being able to determine where the concrete rises, not being able to meet the requirements of on-site construction, and not being able to confirm the quality of the concrete, etc. problem, to achieve the effect of solving the problem of not being easy to sink, preventing secondary labor, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

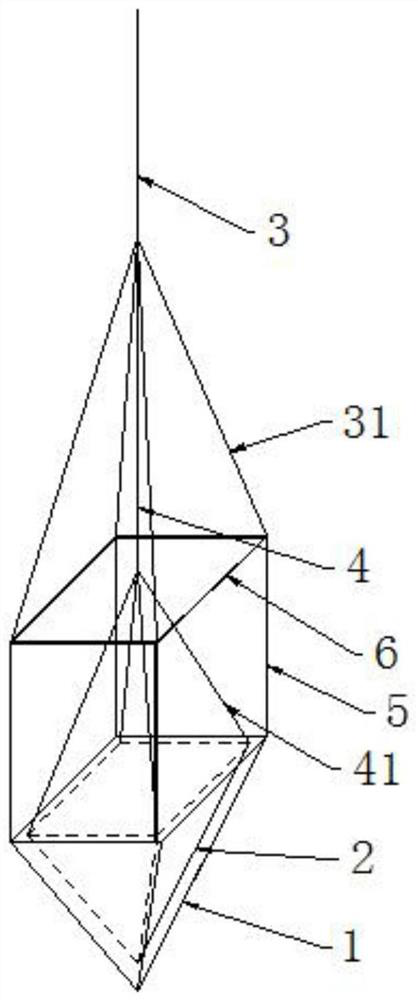

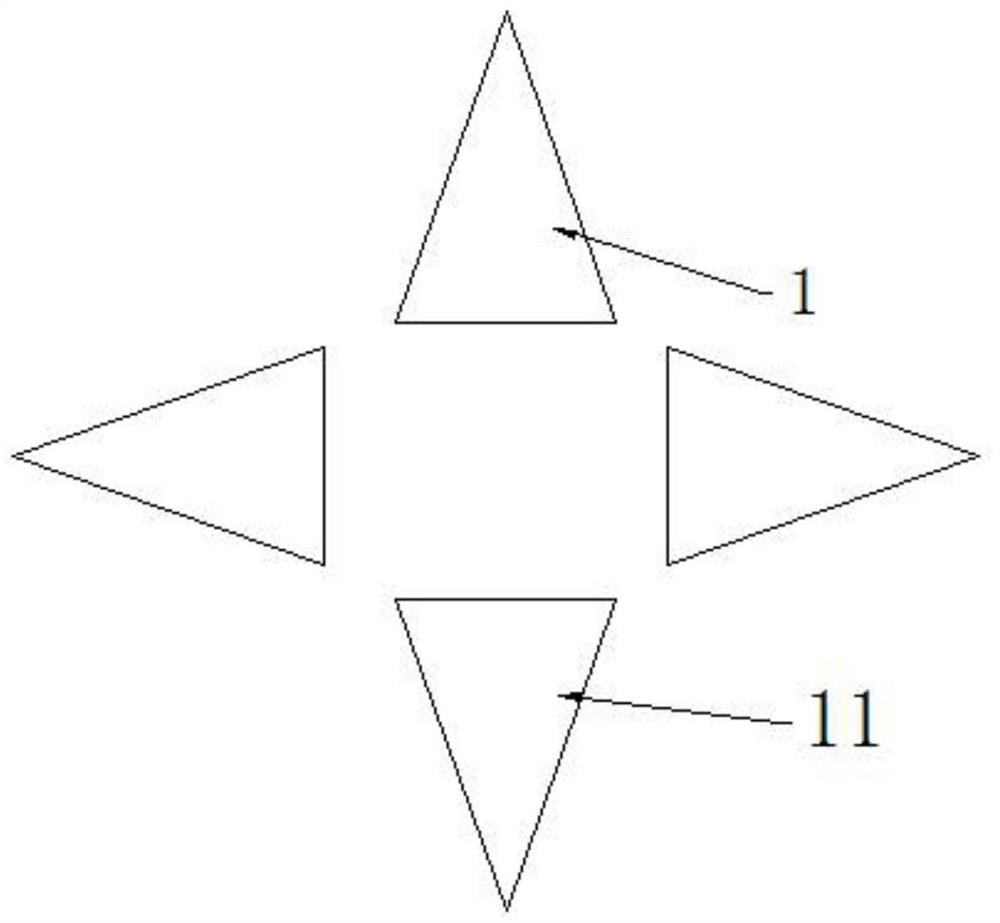

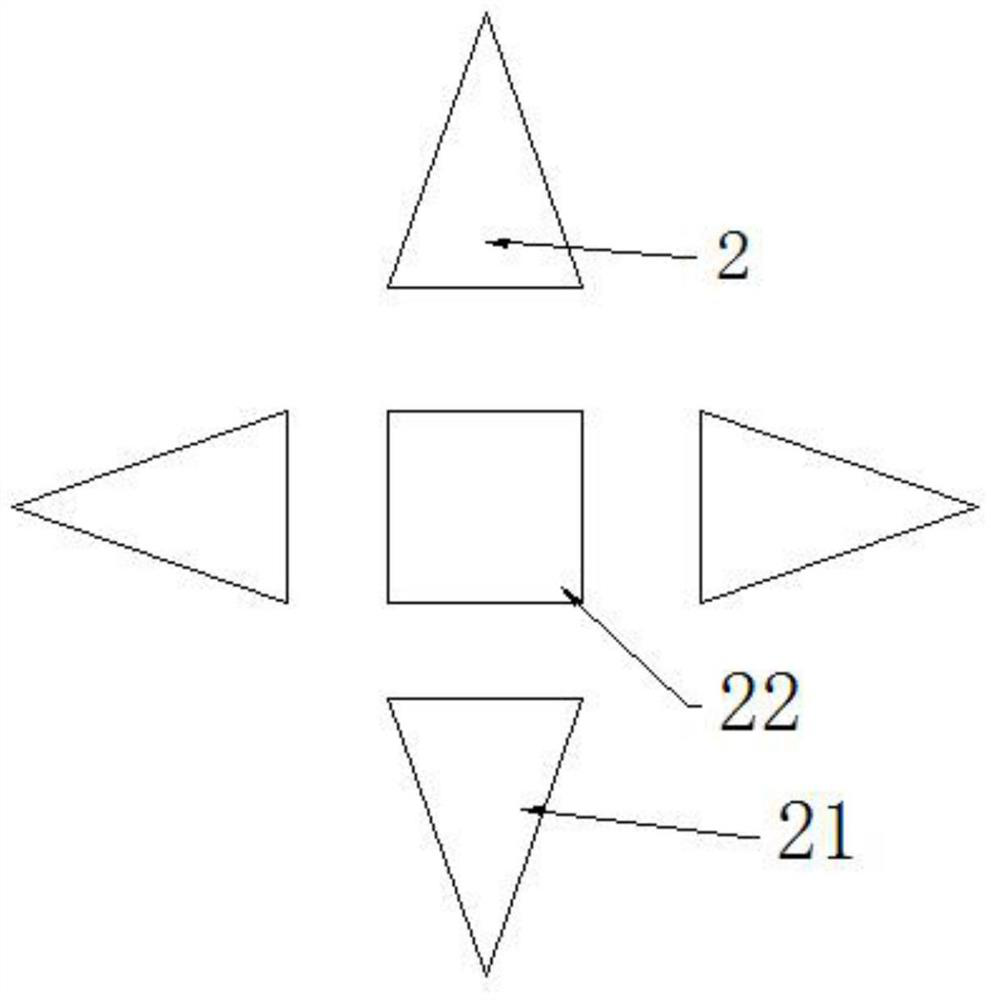

[0038] like Figure 1-3 , The present embodiment proposes a new modular slag comprising an opening provided with a large and a small funnel 1 funnel 2, a small funnel 2 provided in a large hopper 1, a large funnel inner wall and the outer wall of a small funnel 2 by leaving a gap between the supply of material, a small funnel opening portion 2 is detachably connected to the connecting plate 22; a large funnel opening portion is connected to the first main slings 3, small funnel opening portion 2 is connected to the second main sling 4 .

[0039] Detachable connection of the connecting plate 22, on the one hand the connecting plate 22 can form a sealed space inside the small funnel, prevent the entry of concrete, on the other hand, by opening the link plate 22, can be placed in a suitable hopper 1 in a small weight, slag is not easy to solve the problem of sinking, but also will not affect the normal operation slag's.

[0040] In the conventional detection method, by connecting rein...

Embodiment 2

[0055] like Figure 2-4 Shown, other embodiments of a structure with the same, except that, in the present embodiment, the first and second primary master sling sling connection for:

[0056] Large hopper or near the midpoint of an upper end fixedly connected with a vertical midpoint disposed symmetrically round 5, 6 is fixedly connected with a transverse bar between the vertical bar 5, connected to the transverse bar 6 are connected to both ends of a sling 31, the first hanging strap 31 with the other end connected to a first main sling 3; a second main link plate 22 is connected to the sling 4 near the midpoint or neutral position.

[0057] Wherein the vertical bar 5 is two bar φ10 length of 20cm. 4 is a transverse bar length of 15cm round φ10, the same length of the lateral length of the base bar 11 and the large fixed plate 4.

[0058] Pouring concrete pile construction, the need to keep to amount of ascent with a concrete surface measuring rope, in order to control the quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com