Multidirectional synchronous telescopic and vertical lifting composite motion driving device

A compound motion and driving device technology, which is applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of inability to achieve light weight, bloated mechanism, low transmission efficiency, etc., and achieve large-scale synchronous telescopic movement, The effect of improving the smoothness of transmission and reducing the quality of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

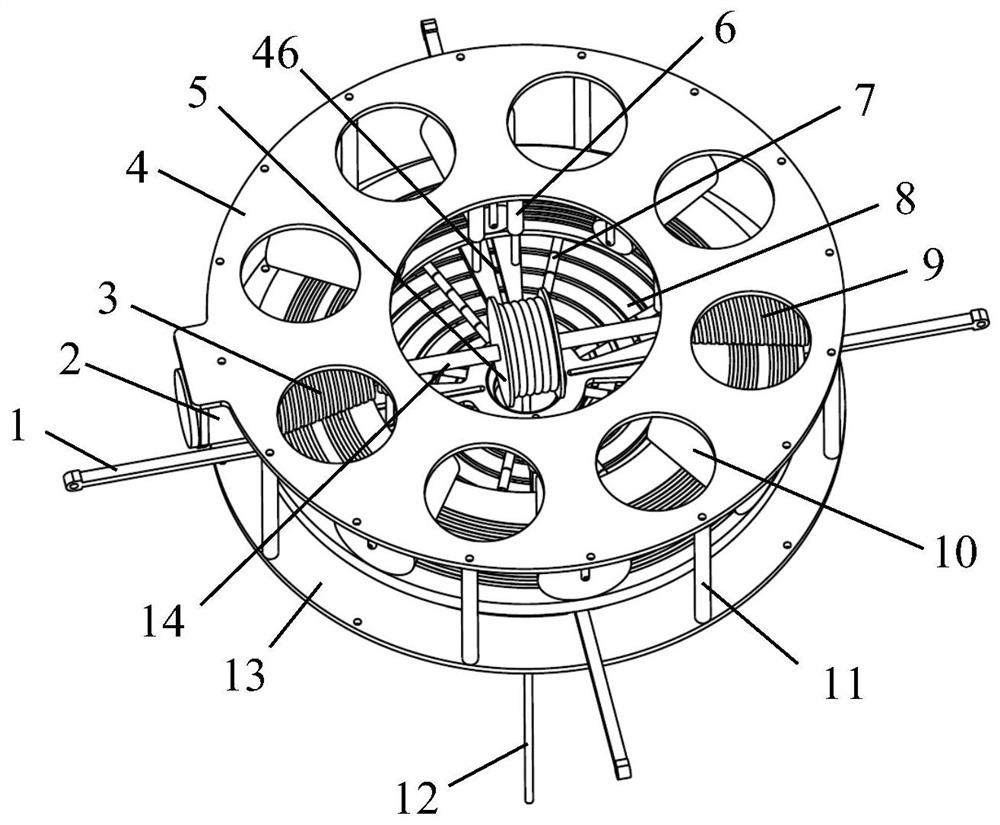

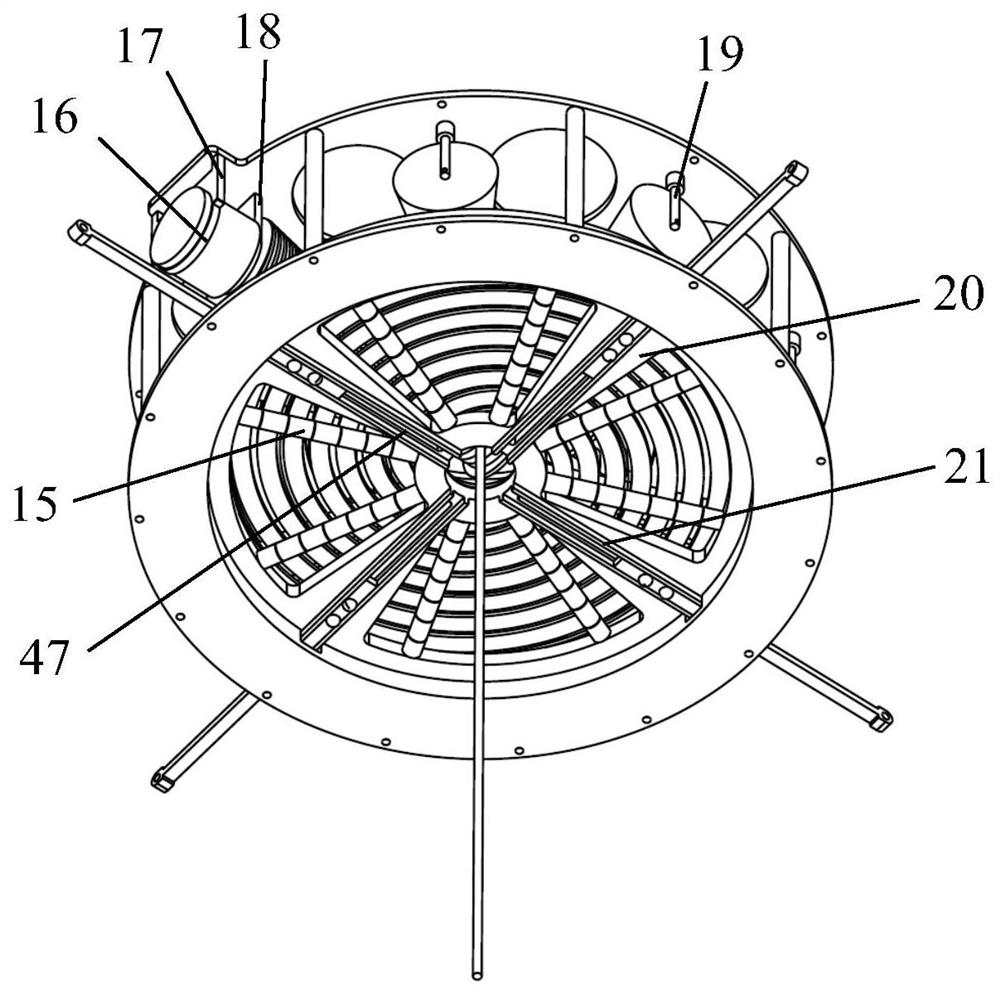

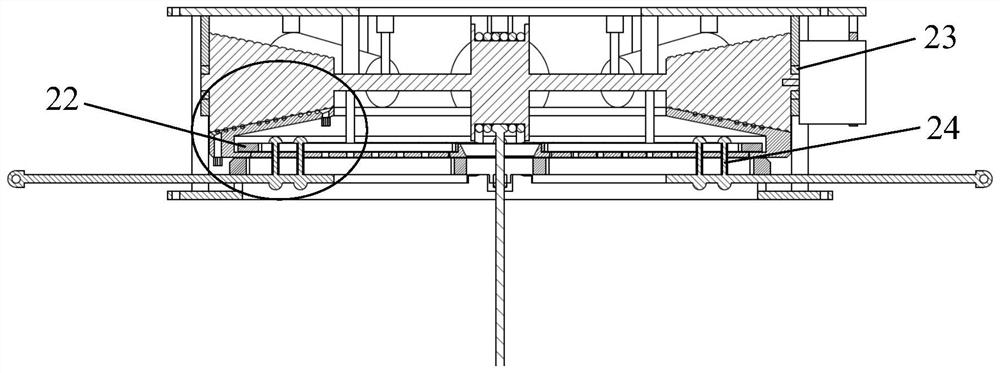

[0034] Design principle of the present invention

[0035] 1. The design principle of the compound motion drive device. The motor drives the cone → the cone drives the hoist to do the lifting movement → at the same time the cone drives the upper plate 44 of the spiral plate to rotate → the upper plate 44 of the spiral plate drives the lower plate 43 of the spiral plate to rotate through the rope → the lower plate 43 of the spiral plate rotates to drive the pins in the lower plate along the The Archimedes spiral groove performs spiral rotation → at the same time, the pin penetrates the lower plate 43 of the spiral plate and enters the linear groove under the plate, and drives the telescopic rod in the linear groove to perform linear motion while doing the spiral motion → the pin moves along the direction of Archimedes Every time the direction of the spiral groove increases one turn towards the direction of the large radius, the telescopic rod in the linear groove will stretch ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com