Visual positioning system, battery replacement equipment and battery replacement control method

A technology for visual positioning and power exchange equipment, applied in the field of visual positioning, can solve problems such as low power exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

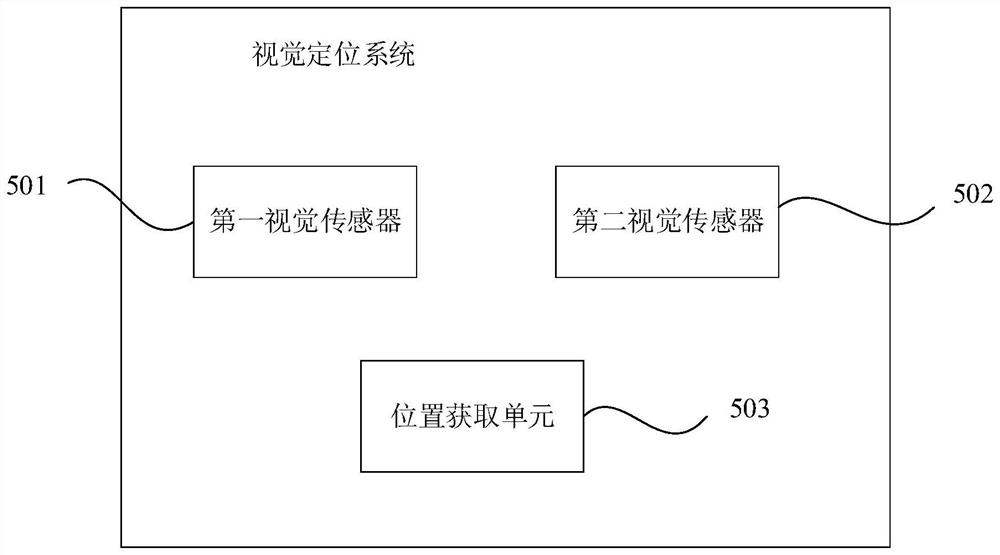

[0083] This embodiment provides a visual positioning system. refer to figure 1 , the visual positioning system includes a first visual sensor 501 , a second visual sensor 502 , and a position acquisition unit 503 .

[0084] The first visual sensor 501 is used to acquire a first image of a first position of the target device; the second visual sensor 502 is used to acquire a second image of a second position of the target device. The location obtaining unit 503 is used to obtain location information of the target device according to the first image and the second image.

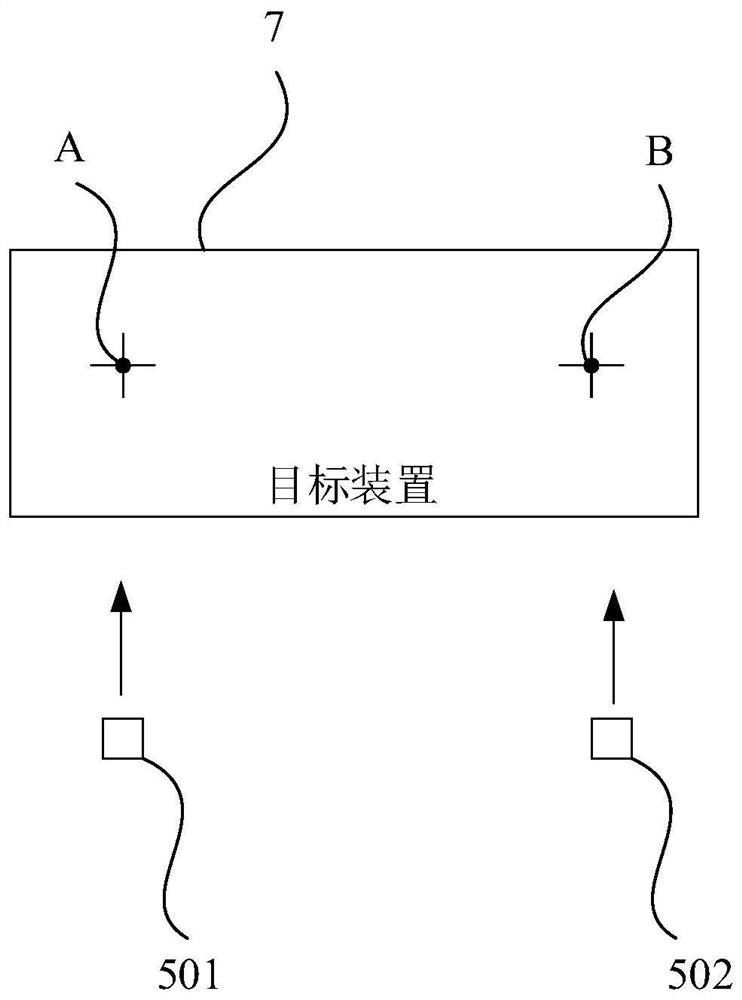

[0085] For specific implementation, refer to figure 2 , the first visual sensor 501 acquires the first image of the target device along the direction indicated by the arrow, the first image includes the first position A on the target device; the second visual sensor 502 acquires the second image of the target device along the direction indicated by the arrow, the first image includes The second image inclu...

Embodiment 2

[0088] On the basis of Embodiment 1, this embodiment provides a visual positioning system. In this embodiment, the position obtaining unit 503 also obtains the position adjustment amount according to the position information of the target device and the reference position information of the target device.

[0089] As an optional implementation, the position acquisition unit 503 performs image processing according to the images acquired in real time by the first visual sensor 501 and the second visual sensor 502 and a preset reference image of the target device to obtain the position adjustment amount.

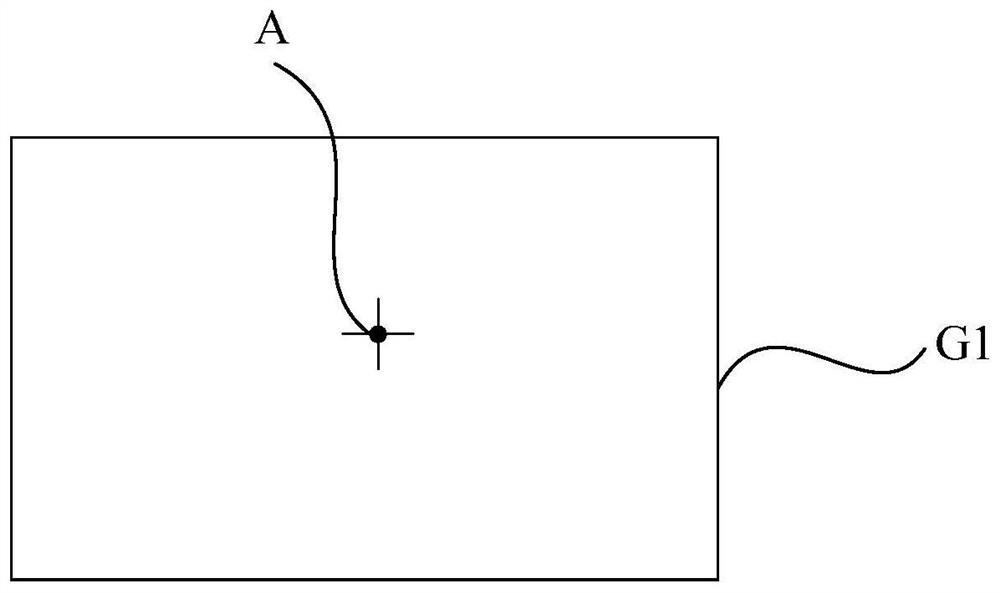

[0090] In an optional implementation manner, the position acquiring unit 503 acquires the horizontal displacement amount according to the first image and the first reference image. image 3 An illustration of the first reference image G1 is given. The first reference image G1 is pre-stored in the location acquisition unit 503 . The first reference image G1 includes a first lo...

Embodiment 3

[0098] This embodiment provides a battery swapping device, which is used for battery swapping of an electric vehicle. refer to Figure 6 , the battery swapping device includes the visual positioning system 801 of Embodiment 1 or Embodiment 2. Taking the battery bracket of the electric vehicle as the target device, the first visual sensor acquires the first image of the first position of the battery bracket; the second visual sensor acquires the second image of the second position of the battery bracket; the position acquisition unit according to the first image The first image and the second image obtain the position information of the battery bracket. The visual positioning system accurately locates the battery bracket by visual means, so that the battery replacement equipment is aligned with the battery bracket with the battery pack locked, thereby realizing accurate battery replacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com