Anti-bending composite cable insulation rubber particle layered filling device

A rubber particle and cable insulation technology, which is applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve the problems of increasing cable torsional force, prone to bending, and prone to circuit breakage, so as to increase cable torsional force , prevent bending, and prevent offset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

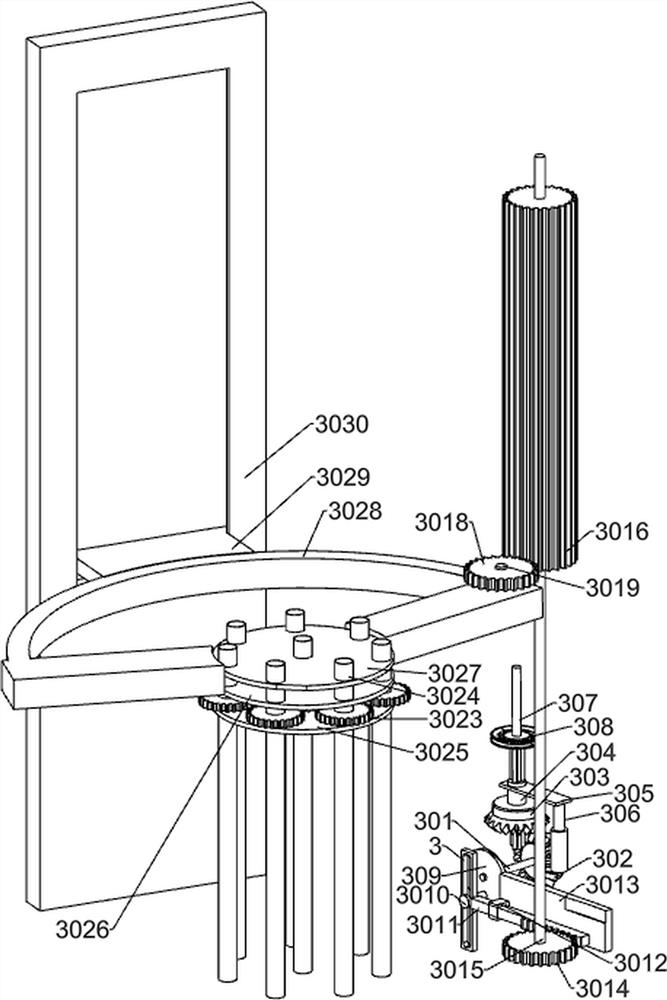

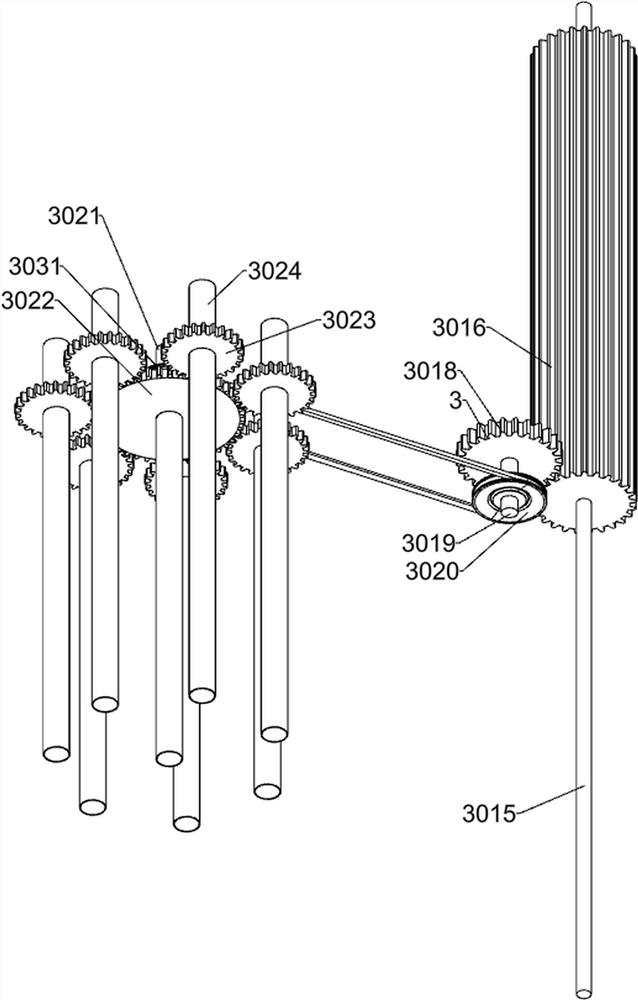

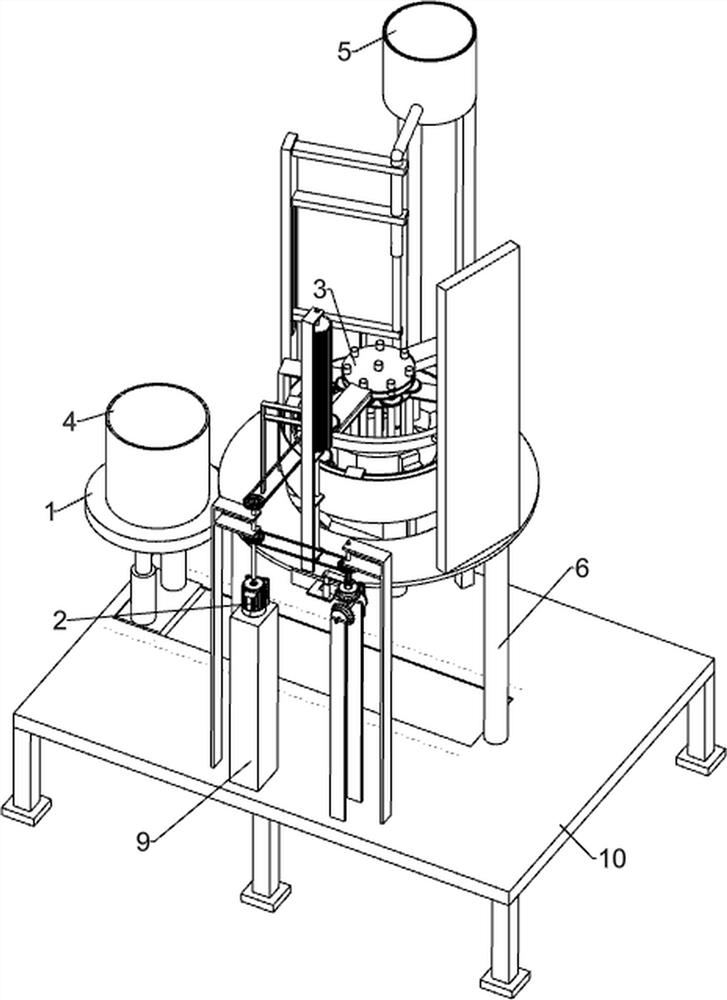

[0030] An anti-bending composite cable insulating rubber particle layered filling device, such as Figure 1-9 As shown, it includes a conveying mechanism 1, an anti-bending mechanism 2, a micro-rotation take-out mechanism 3, a simulated cable jacket 4, a rubber particle storage bucket 5, a first fixed column 6, a second fixed column 7, a third fixed column 8, The support frame 9, the fixed frame 10 and the controller 11; the conveying mechanism 1 is connected with the analog cable jacket 4; the conveying mechanism 1 is connected with the fixed frame 10; the side of the conveying mechanism 1 is provided with an anti-bending mechanism 2; the anti-bending mechanism 2 It is connected with the micro-turn take-out mechanism 3; the anti-bending mechanism 2 is connected with the rubber particle storage barrel 5; the anti-bending mechanism 2 is connected with the first fixed column 6; the anti-bending mechanism 2 is connected with the second fixed column 7 The anti-bending mechanism 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com