Automatic tray placing device for greenhouse seedling trays

A technology for hole trays and seedling holes, which is applied in the field of automatic tray placement devices, can solve problems such as complex process, low efficiency, and general effect of mechanical tray placement, and achieve the effects of low cost, reduced labor intensity, and improved tray placement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

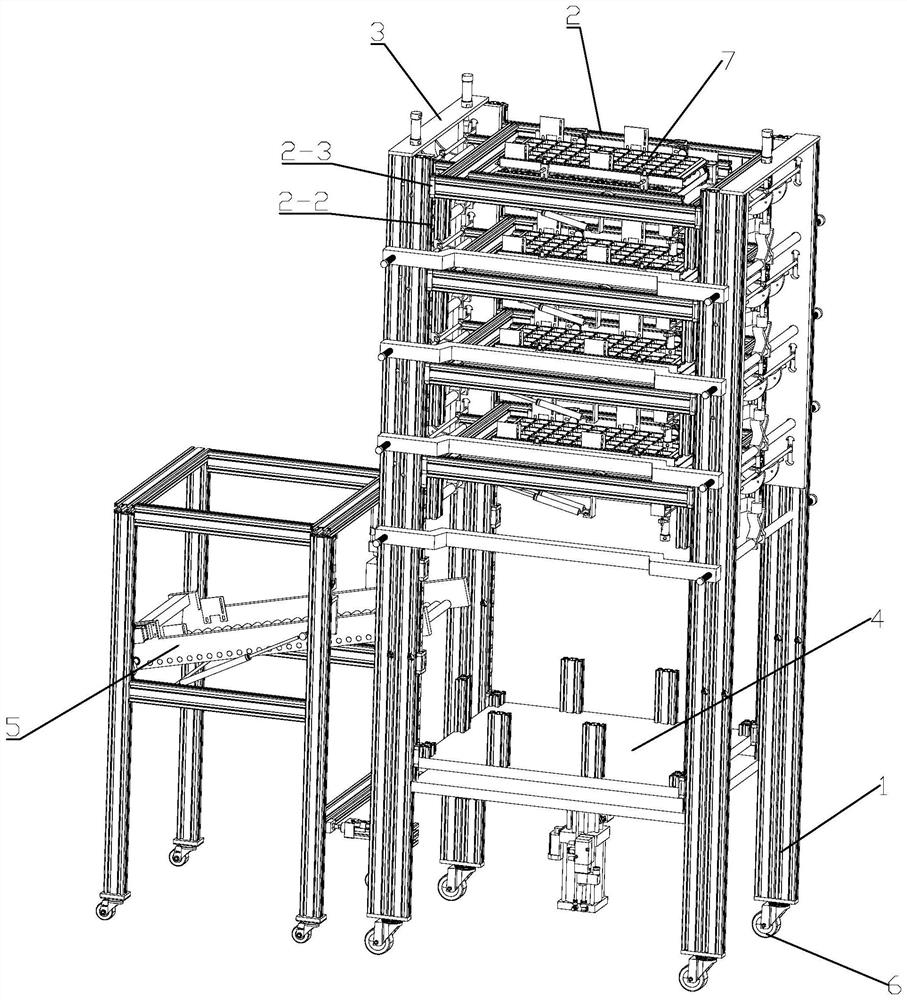

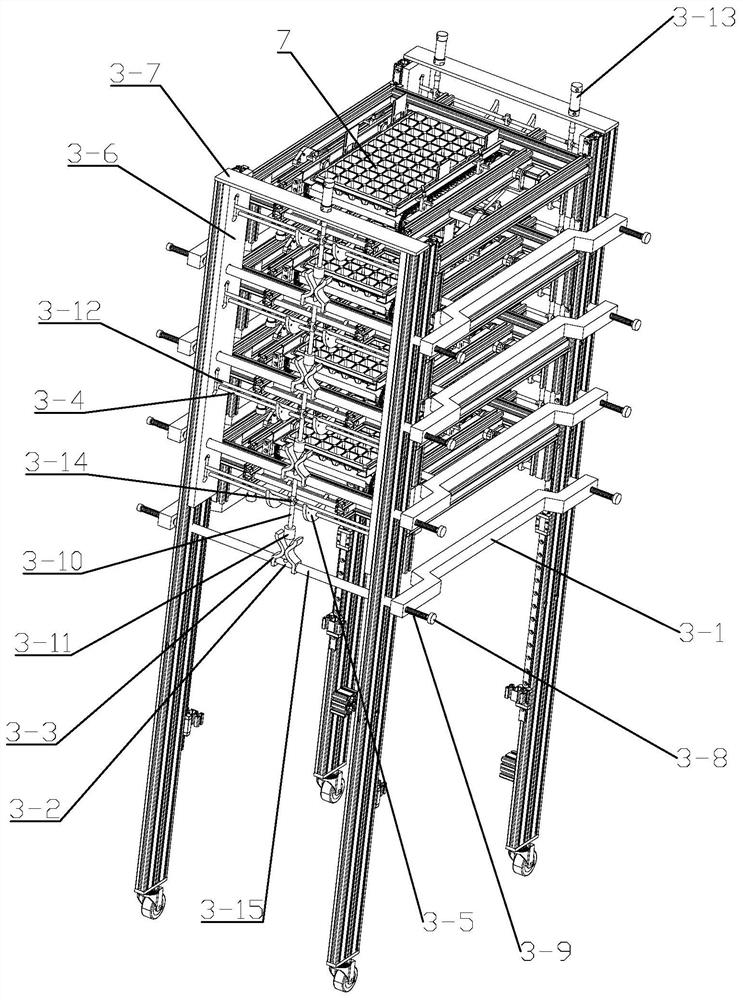

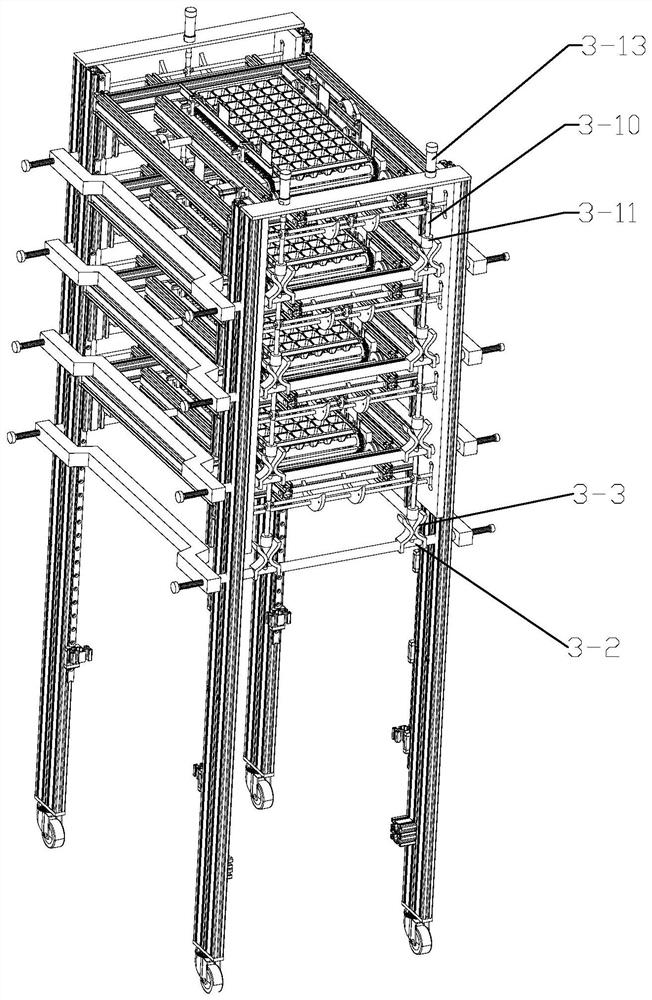

[0033] Such as figure 1 The shown automatic tray-discharging device with seedling trays in the greenhouse includes a frame 1, a plurality of tray lifting and turning conveying mechanisms 2, a positioning mechanism 3, a tray transport frame reset mechanism 4 and a tray transfer tray mechanism 5. In this embodiment, the frame has four layers, and each layer is provided with a lifting and turning conveying mechanism for the tray. Rollers 6 are installed at the bottom of the frame.

[0034] Such as Figure 1 to Figure 5 As shown, the four tray lifting and turning conveying mechanisms are arranged sequentially from top to bottom; each tray lifting and turning conveying mechanism includes a sliding frame 2-1, a power roller conveyor 2-4 and several (two in the figure) Flip cylinders 2-6. The sliding frame can vertically slide along the frame through the slidin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap