Universal tool and method used for ring section type part cutoff machining

A technology for cutting and machining parts, applied in the field of machining of ring-segment parts, can solve the problems of large demand for special fixtures, many types of ring-segment parts, and difficulty in fixture conversion, so as to reduce the quality loss of parts, reduce the processing time, The effect of shortening production lead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

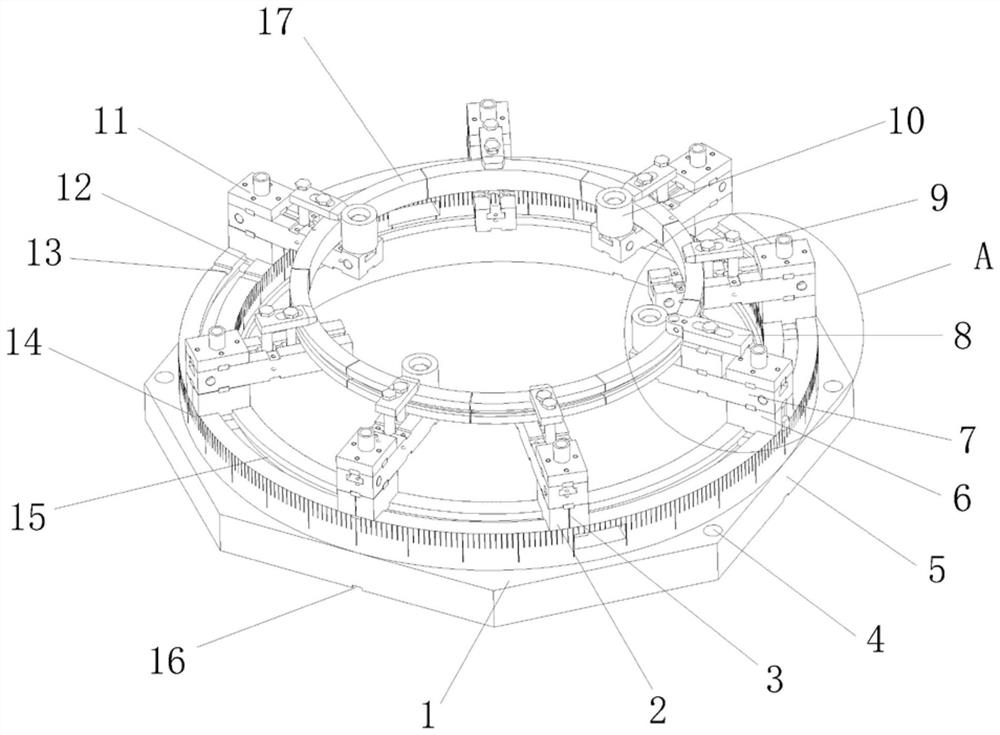

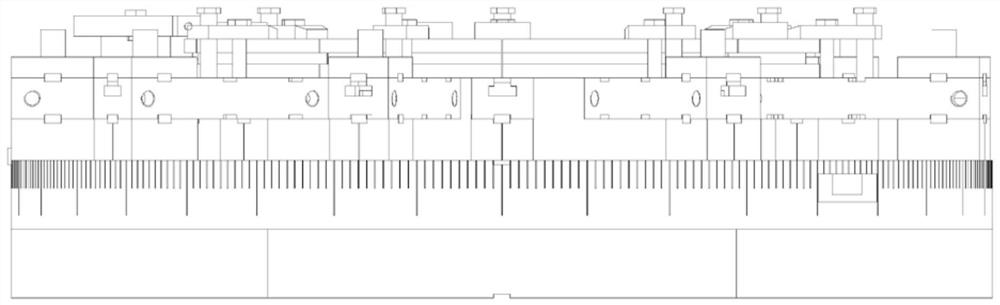

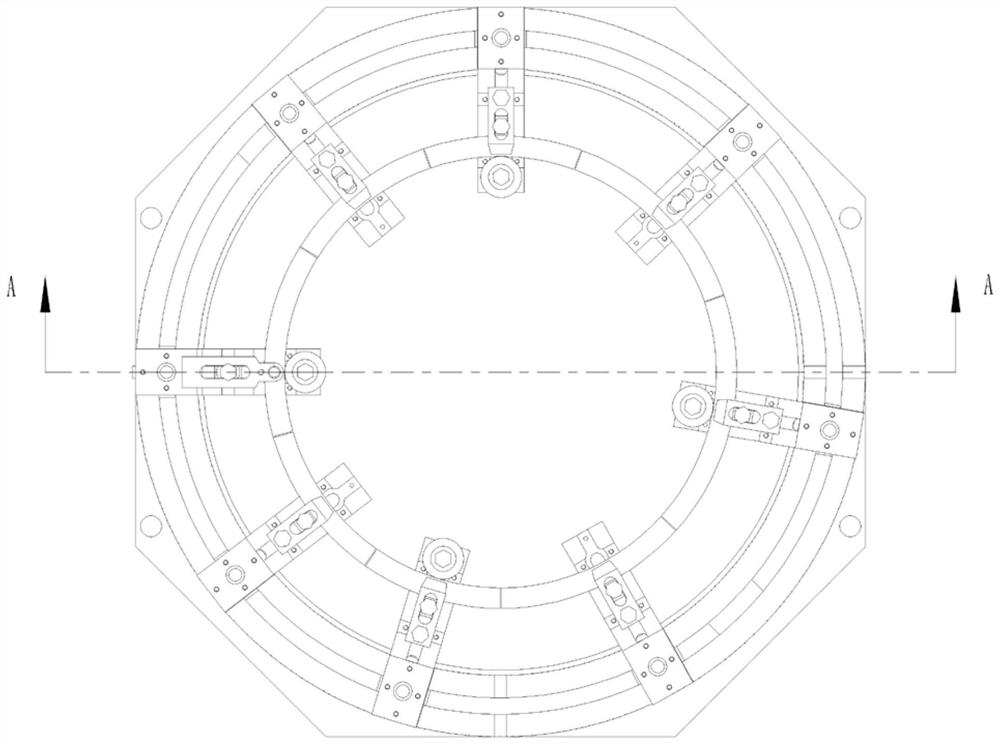

[0034] Such as figure 1 As shown, a universal tool for cutting and processing ring-like parts, including a base body 1, a circumferential positioning adapter slider 6, a circumferential adapter slider 2, an extension plate 7 and a positioning joint 11, the circumferential The positioning transfer slider 6 and the circumferential transfer slider 2 are arranged on the base body 1 through key grooves, and the upper parts of the circumferential positioning transfer slider 6 and the circumferential transfer slider 2 are sequentially provided with extension plates. 7 and the positioning joint 11, and fasten one end of the extension plate 7 with the positioning joint 11 and the circumferential positioning transfer slid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap