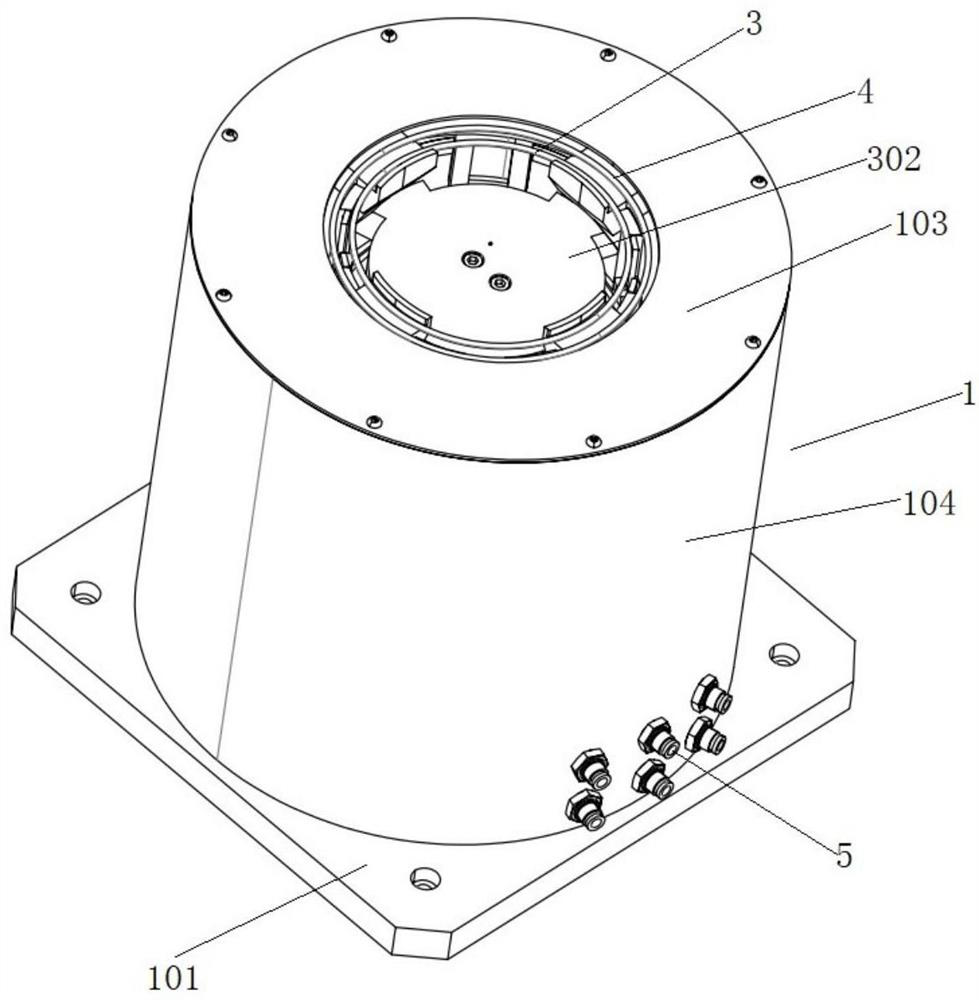

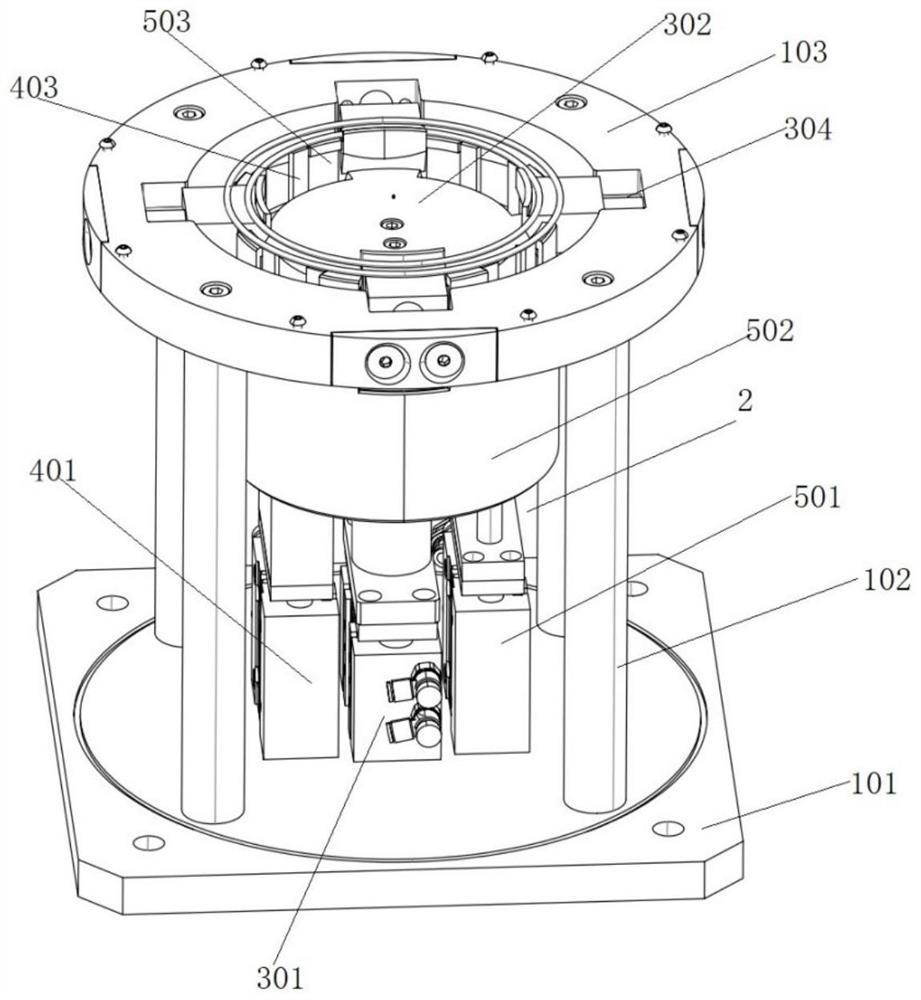

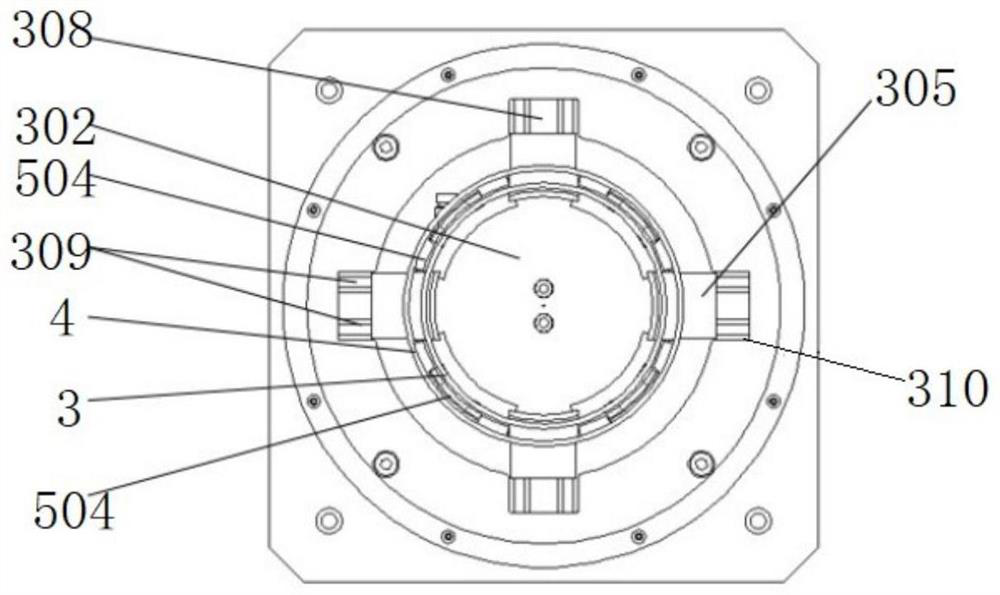

Large-diameter sealing ring assembling device and method

A technology for assembling devices and sealing rings, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of single workload of manual assembly of sealing rings, unsaturated working conditions of workers, and increased manual work content, etc., to achieve low Cost, the effect of solving industry difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0050]At present, in the automatic assembly industry, the overall shape of small-diameter sealing rings is relatively stable, but it is difficult to automatically assemble larger-diameter sealing rings, especially when the sealing rings are easily deformed and cannot be directly screened and grabbed. The assembly industry is particularly difficult. In the actual production and assembly process, the sealing ring assembly process is often interspersed in the middle process of the entire process assembly, where manual assembly is often used, and because the workload of manual assembly of the sealing ring is relatively simple and single, it is not saturated for the working conditions of the workers. , Enterprises will increase the content of manual work by reducing the equipment for automatic assembly of pre- and post-sequences. As a result, the degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com