Warehouse management personnel freight cart based on enterprise collection and supply management

A warehouse management and enterprise technology, applied in the field of procurement and supply management, can solve problems such as labor and labor, and achieve the effect of avoiding tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

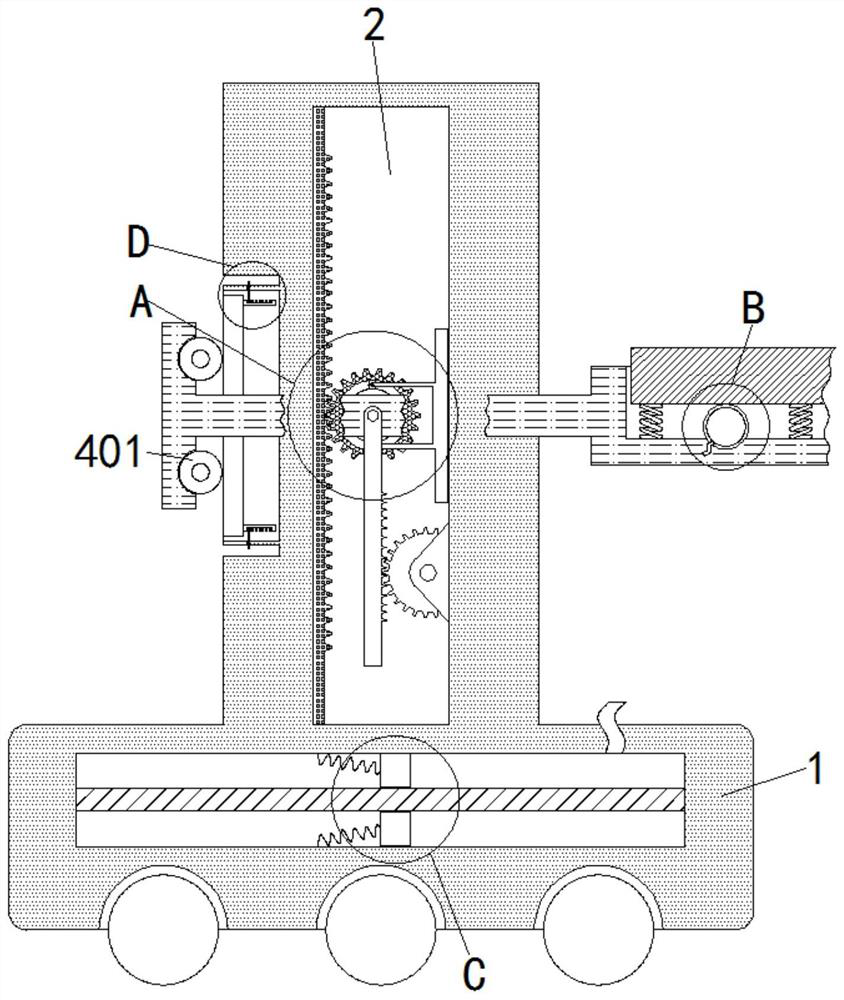

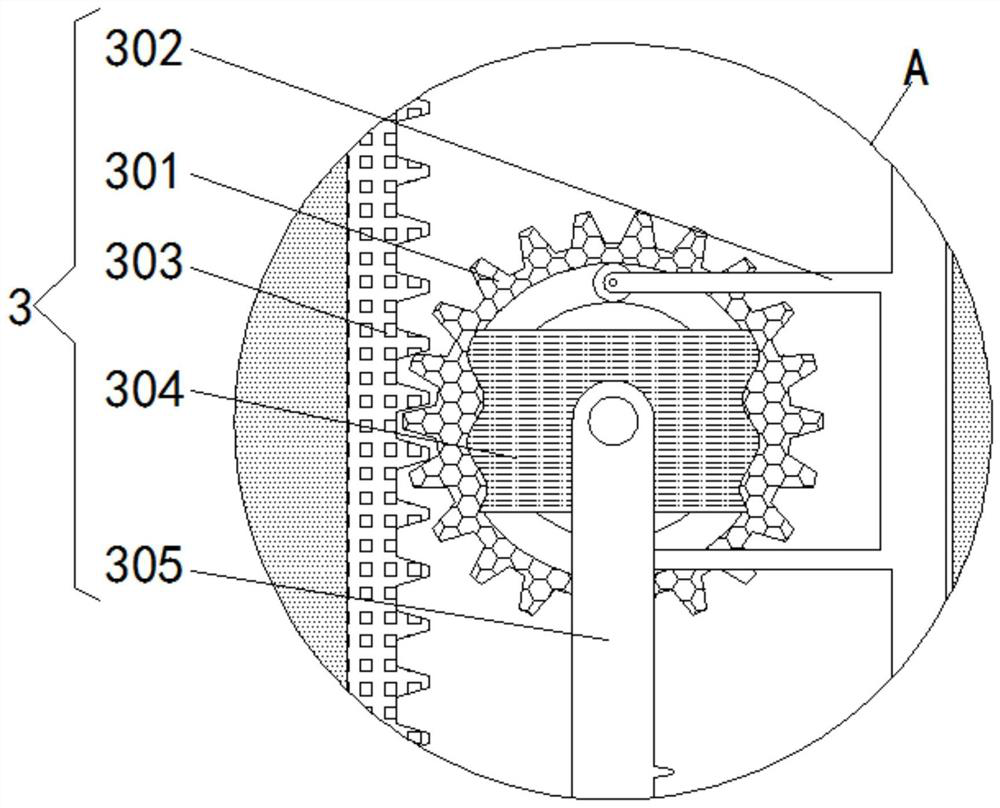

[0025] Example 1: Please refer to Figure 1-4 , a cargo trolley for warehouse personnel based on enterprise procurement and supply management, including a base 1, a chute 2 is opened on the side of the base 1, a lifting mechanism 3 is fixedly installed inside the base 1, and the left side of the base 1 An adjustment mechanism 4 is provided on the side, and a climbing wheel 301 is arranged inside the lifting mechanism 3. The left side of the climbing wheel 301 is meshed with a vertical tooth plate 303, and the surface of the climbing wheel 301 is slidingly connected with a balance frame 302. The right side of the balance frame 302 The side slides close to the right side of the inner wall of the chute 2, and the center of the surface of the climbing wheel 301 is rotated and connected with a cross bar 304, and the surface of the cross bar 304 is rotated and connected with a lifting gear rod 305, and the right side of the lifting gear rod 305 is meshed with a driving gear. Wheel, ...

Embodiment 2

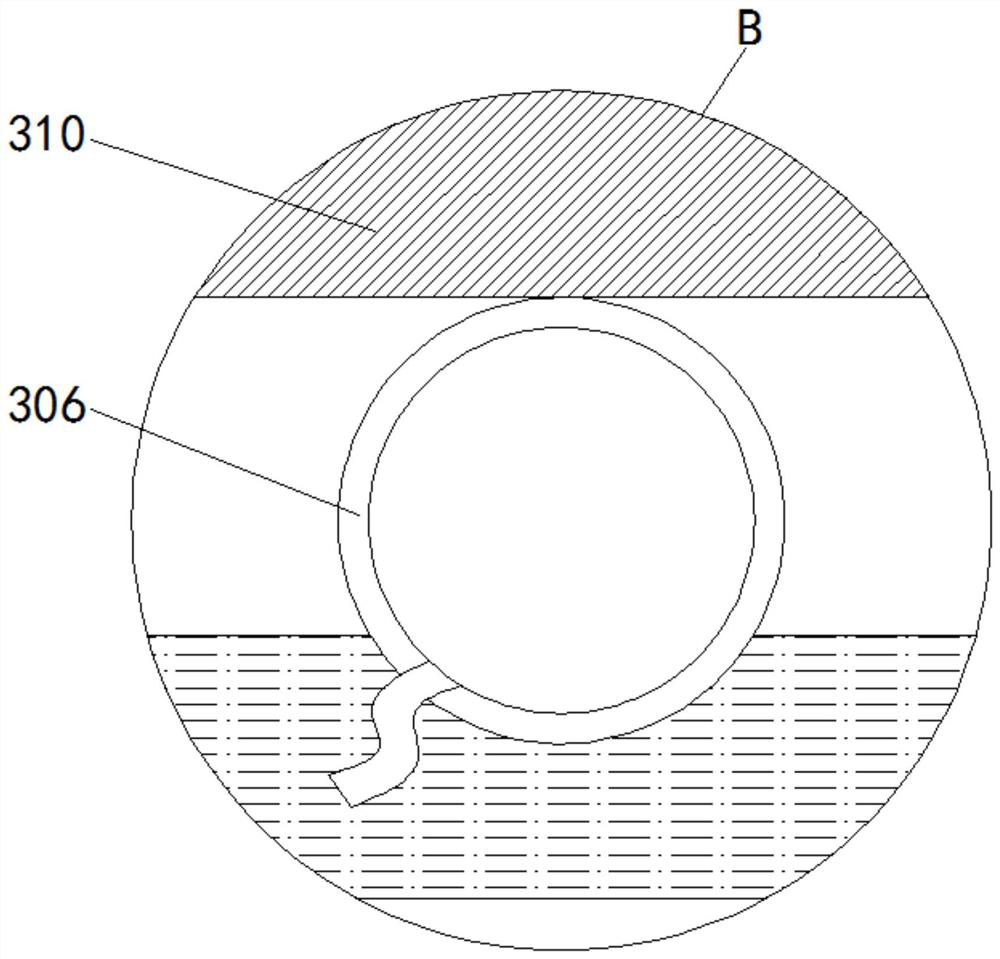

[0026] Example 2: Please refer to Figure 4-5 , a cargo trolley for warehouse personnel based on enterprise procurement and supply management, including a base 1, a chute 2 is opened on the side of the base 1, a lifting mechanism 3 is fixedly installed inside the base 1, and the left side of the base 1 An adjustment mechanism 4 is arranged on the side, and a roller 401 is arranged inside the adjustment mechanism 4. The right side of the roller 401 is rollingly connected with a squeeze plate 403, and the right side of the squeeze plate 403 is fixedly connected with a clamping rod 402, and the side of the clamping rod 402 is inserted into the A limit rod 404 is provided, and the limit rod 404 clamps the locking rod 402 initially.

Embodiment 3

[0027] Example 3: Please refer to Figure 1-5 , a cargo trolley for warehouse personnel based on enterprise procurement and supply management, including a base 1, a chute 2 is opened on the side of the base 1, a lifting mechanism 3 is fixedly installed inside the base 1, and the left side of the base 1 An adjustment mechanism 4 is provided on the side, and a climbing wheel 301 is arranged inside the lifting mechanism 3. The left side of the climbing wheel 301 is meshed with a vertical tooth plate 303, and the surface of the climbing wheel 301 is slidingly connected with a balance frame 302. The right side of the balance frame 302 The side slides close to the right side of the inner wall of the chute 2, and the center of the surface of the climbing wheel 301 is rotated and connected with a cross bar 304, and the surface of the cross bar 304 is rotated and connected with a lifting gear rod 305, and the right side of the lifting gear rod 305 is meshed with a driving gear. Wheel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com