Double-station stacker-based warehouse system and control method thereof

A control method and stacker technology, applied in the field of storage, can solve the problems of low efficiency and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

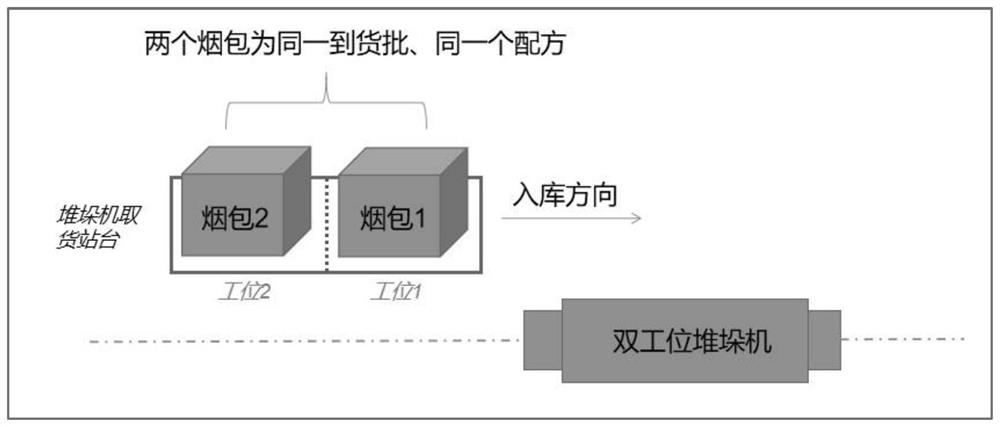

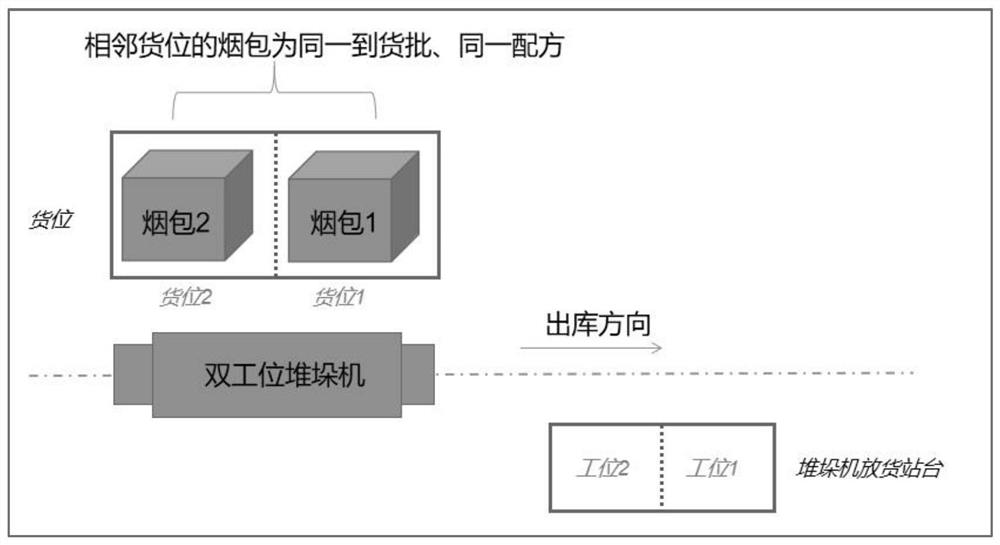

[0028] The composition of the warehouse system proposed by the present invention includes: pallet conveying line: that is, the conveying chain machine controlled by the bottom electric control; double-station stacker: the double fork of the stacker can be used to take and put the two pallets of goods at the same time; Host system: the computer system that controls the allocation strategy of storage and delivery locations

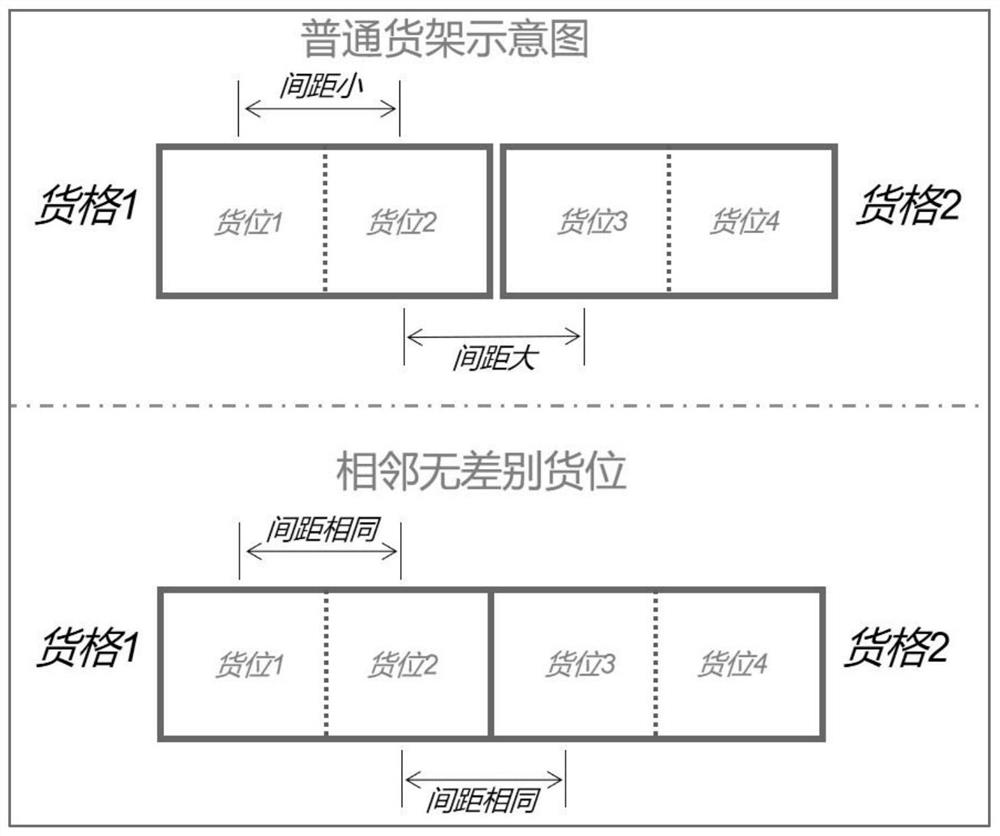

[0029] The design of storage space is adjacent without difference. The space includes: all aisles use shelves with no difference in the distance between the two spaces in adjacent rows on the same floor, and the two adjacent spaces of the same shelf and the two adjacent goods of the adjacent shelf are used. The position spacing is the same, which meets the spacing of the double forks of the double-station stacker. The distance between the two stations where the pallet is parked on the pick-up platform at the storage entrance of the stacker and the unloading ...

Embodiment 2

[0053] Create a storage plan when the formula library is loaded into the warehouse. The storage plan includes information such as formula information, grades of cigarette packs to be stored, and the quantity to be stored. There are RFIDs on the incoming cigarette packs that can identify the grade information of the packs. When warehousing, check the warehousing cigarette packs by confirming the warehousing plan and identifying the RFID information of the cigarette packs. If the check is correct, the cigarette pack information binding formula will be created. The stacker performs the warehousing task of double-forks, taking and putting together. When leaving the warehouse, a delivery plan is created, and the delivery formula is obtained according to the delivery plan, so that the delivery cigarette packs are locked for delivery according to the delivery strategy of the present invention. When leaving the warehouse, scan the RFID on the cigarette pack to verify the information....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com