Organic electroluminescent material, electronic component and electronic device

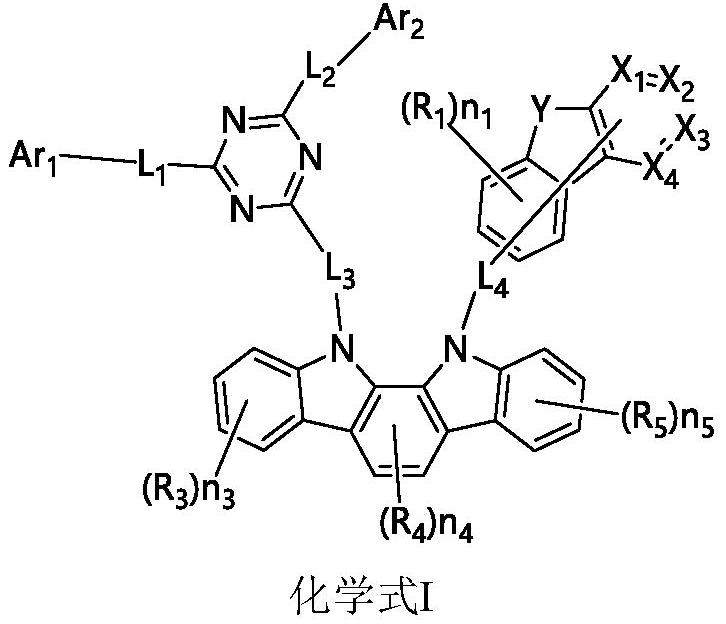

An electroluminescent material and luminescent technology, applied in luminescent materials, electrical components, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

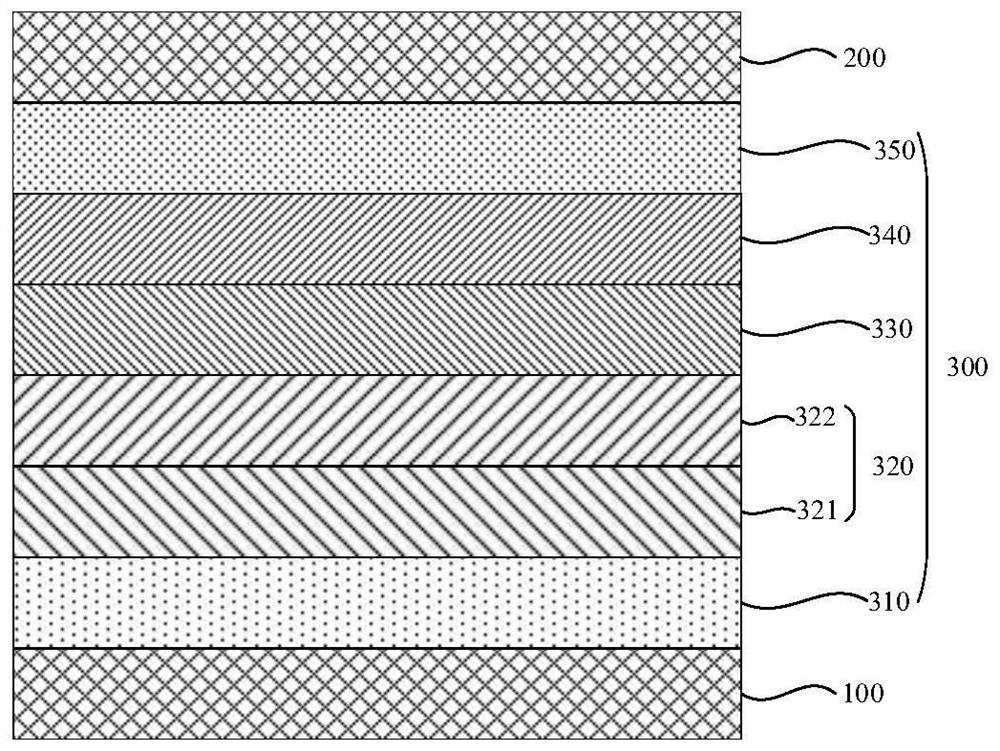

[0303] The anode is prepared by the following process: the thickness is The ITO substrate (manufactured by Corning) was cut into a size of 40mm × 40mm × 0.7mm, and a photolithography process was used to prepare it into an experimental substrate with patterns of cathodes, anodes and insulating layers, using ultraviolet ozone and O 2 :N 2 A plasma surface treatment was performed to increase the work function of the anode (experimental substrate) and to remove scum.

[0304] Vacuum evaporation of F4-TCNQ on the experimental substrate (anode) to form a thickness of The hole injection layer (HIL), and NPB was evaporated on the hole injection layer to form a thickness of the first hole transport layer.

[0305] PAPB was vacuum evaporated on the first hole transport layer to form a thickness of the second hole transport layer.

[0306] On the second hole transport layer, compound 1:GH-N:Ir(ppy) 3 Co-evaporation was performed at a ratio of 60:40:10% (co-evaporation rate rati...

Embodiment 2~ Embodiment 89

[0310] Organic electroluminescent devices were fabricated by the same method as in Example 1, except that the compounds shown in Table 11 were used instead of Compound 1 when forming the light-emitting layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com