Fastening device for emergency maintenance of ship

An emergency repair and fastening device technology, applied in the direction of connecting components, nails, staples, etc., can solve the problems of casualties, failure to stop losses in time, insufficient fastening strength of nails and nail guns, etc., to reduce kinetic energy. , Not easy to accidentally hurt, easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

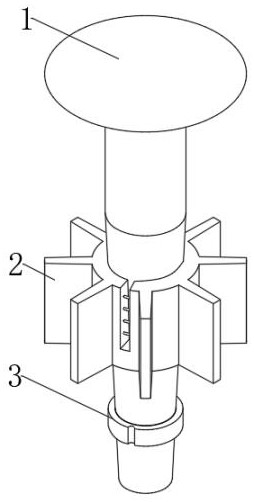

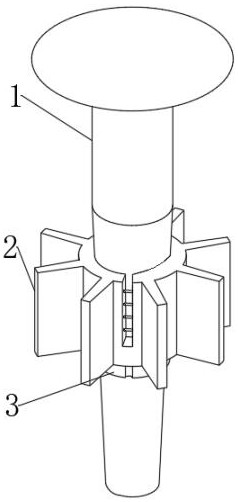

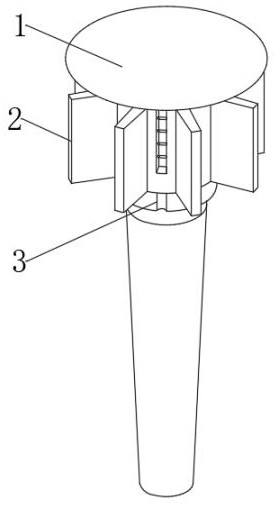

[0040] see figure 1 and Figure 7-10 , a fastening device for emergency maintenance of ships, comprising a nail body 1, the nail body 1 includes a nail body and a nail cap fixedly connected to each other, the diameter of the nail body away from the top cap gradually decreases, the nail body is covered A gear ring 2 and a lubricating ring 3 are provided. The lubricating ring 3 is located on the side of the gear ring 2 away from the top cap. The lubricating ring 3 includes an elastic rubber ring 301. A filling cavity 303 is dug in the elastic rubber ring 301. The filling cavity 303 is filled with Lubricating oil, the inner wall of the elastic rubber ring 301 has a plurality of capillary cracks 305, and the plurality of capillary cracks 305 run through the elastic rubber ring 301 to connect the filling cavity 303 with the outside world, and the capillary cracks 305 are closed by hot melt adhesive. It is fixedly connected with an elastic net 306 matching itself.

[0041] see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com