Mechanical stove air-fuel ratio control device and valve path tapping method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

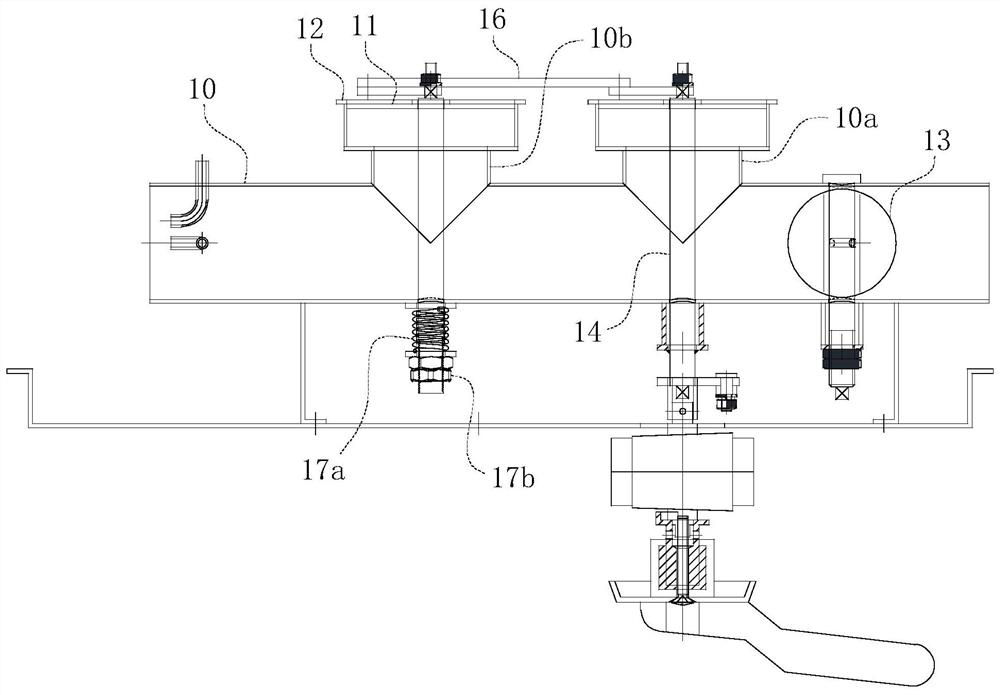

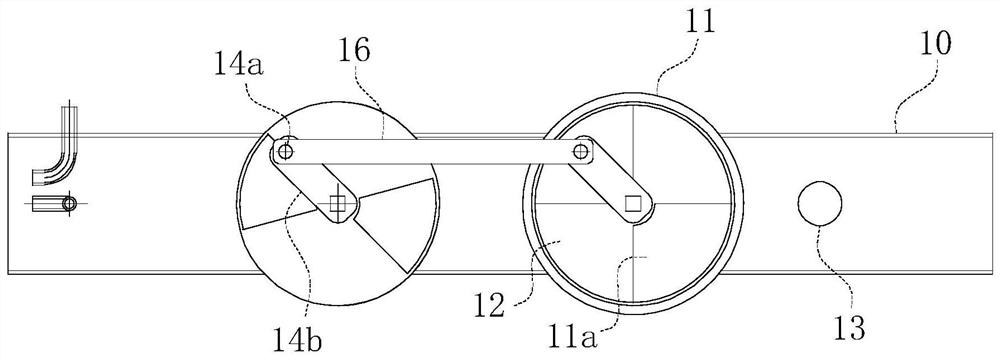

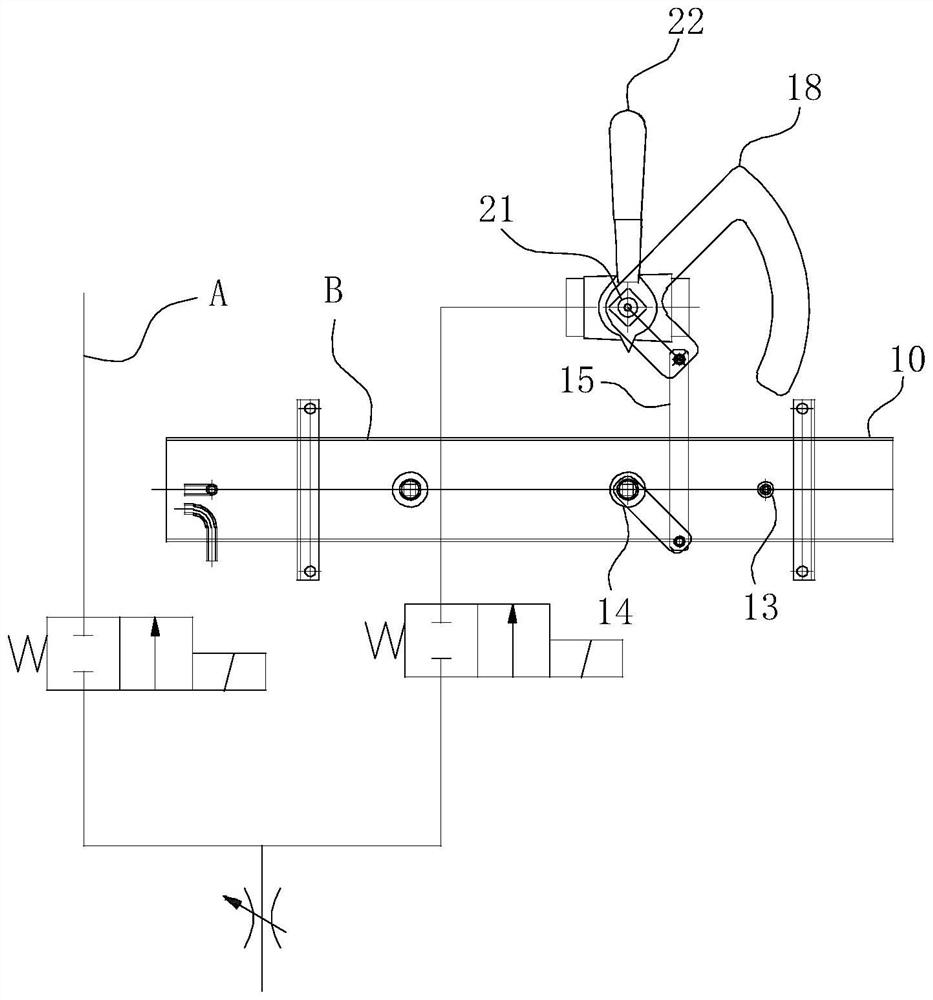

[0041] For ease of understanding, combined here Figure 1-3 , the concrete structure and working mode of the present invention are further described as follows:

[0042] Concrete structure of the present invention refers to Figure 1-2 As shown, during assembly, the present invention realizes the accurate control of the air-fuel ratio by bypassing the air volume of the fan by shunting and releasing pressure; the principle is that the theoretical air volume Q 0 = Air volume Q required by the burner 1 +Bypass shunt air volume Q 2 . When working: the blower fan is located at the front end of the invention so as to communicate with the air inlet, while the burner is located at the rear end of the invention and communicates with the air outlet. The air regulating shaft 21 at the gas valve of the burner and the air regulating shaft 14 at the main flow distribution and pressure relief pipe 10a are synchronously driven through coaxial or sprocket connection or eccentrically hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com