Complex environment test and calibration device, system and method for gas sensor

A gas sensor and complex environment technology, applied in the field of calibration, can solve problems such as large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

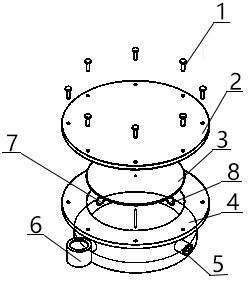

[0029] Such as figure 1 , the present embodiment proposes a complex environment testing and calibration device for a gas sensor, including a stainless steel cylinder 4, a stainless steel cylinder head 2, a vacuum pressure gauge 6, an aviation plug 5 and two air valves, wherein the stainless steel cylinder head 2 passes through The screw 1 connects the stainless steel cylinder 4, and the standard hole connected with the external equipment is set on the stainless steel cylinder 4, and the standard hole includes the first standard hole, the second standard hole, the third standard hole 7 and the fourth standard hole 8, so The aviation plug 5 is installed in the first standard hole, the vacuum pressure gauge 6 is installed in the second standard hole, and the two air valves are installed in the third standard hole 7 and the fourth standard hole 8 respectively.

[0030] Further, the stainless steel cylinder head 2 is provided with an observation window.

[0031] Further, the stain...

Embodiment 2

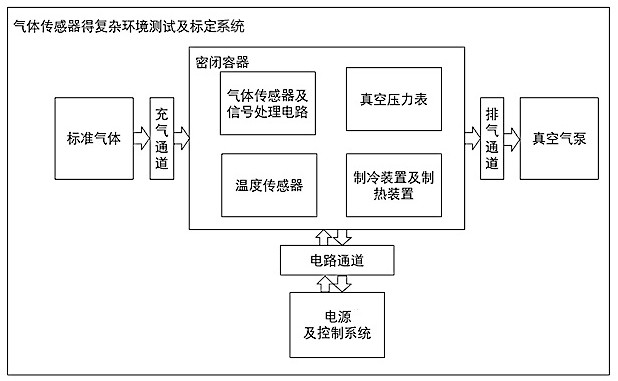

[0040] On the basis of Embodiment 1, this embodiment further proposes a complex environment testing and calibration system for gas sensors, such as figure 2, including a complex environment testing and calibration device for a gas sensor, standard gas equipment, a control system and a vacuum pump equipment as described above, wherein the standard gas equipment is connected to a complex environment testing and calibration of a gas sensor through an inflatable channel Calibration device, the vacuum air pump equipment is connected to a complex environment test and calibration device of a gas sensor through an exhaust channel, the control system is connected to a complex environment test and calibration device of a gas sensor through a circuit channel, the gas charging channel and The exhaust channels are respectively connected to two gas valves provided on a complex environment testing and calibration device of a gas sensor, and the circuit channel is connected to an aviation plu...

Embodiment 3

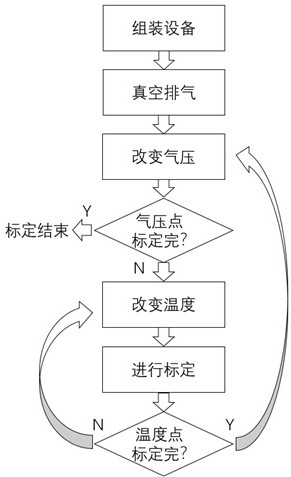

[0044] On the basis of Embodiment 1, this embodiment further proposes a complex environment testing and calibration method for gas sensors, such as image 3 , including the following steps:

[0045] S1. Place the gas sensor and signal processing circuit in the stainless steel cylinder 4, and connect it to the control system through the circuit channel connecting the aviation plug 5, and connect the refrigeration device, heating device, and temperature sensor to the control system through the circuit channel, Then the stainless steel cylinder 4 is sealed by the stainless steel cylinder head 2;

[0046] S2. Open the air valve connected to the exhaust passage, and exhaust the stainless steel cylinder 4 through the vacuum pump. When the vacuum pressure gauge 6 reaches about -0.1mpa, close the air valve of the exhaust passage. At this time, the inside of the container can be considered to be in a vacuum state ;

[0047] S3. Open the air valve connected to the inflatable channel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com