High-stability transformer with overheating early warning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

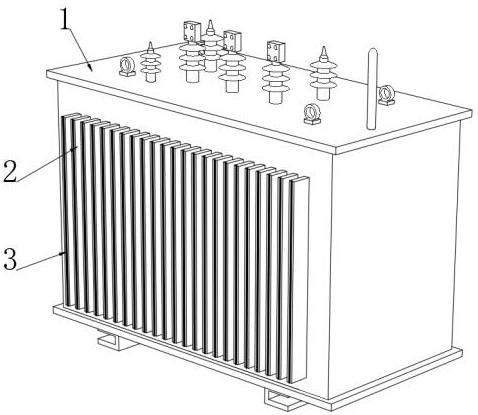

[0036] See figure 1 A high stability transformer of overheating warning, including transformer body 1, and a plurality of uniform distributed heat dissipation flakes 2 are connected outside the outer end of the transformer body 1, and a concentrating strip 3 is provided toward the outer end.

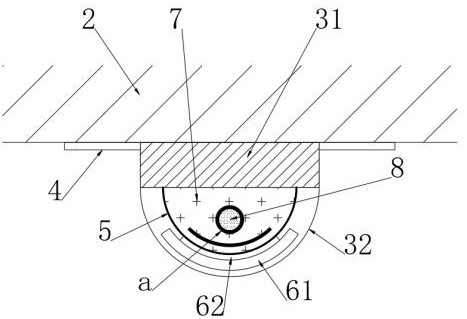

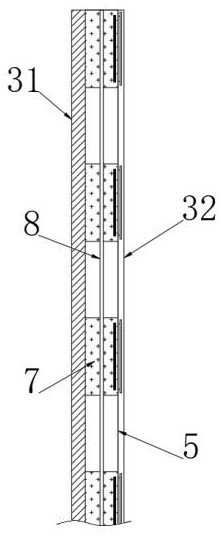

[0037] See figure 2 The outer end of the concentrating strip 3 is fixedly coupled to the adhesive film 4, the helper bottom sheet 4 and the heat dissipation flake 2 are bonded, and the concentrating strip 3 includes a heat absorbing layer 31 and a light-changing color layer fixed to the heat absorbing layer 31. 32. The heat absorbing layer 31 is attached to each other, and the heat shifting layer 31, the photoreactive color layer 32, and the bonding surface 4 are made of high thermal conductivity materials, so that the setting of the concentrating strip 3 is not easy to affect the transformer body. 1 The upper air is overflowing, it is not easy to cause heat dissipation, and the thermal bloc...

Embodiment 2

[0043] Based on the embodiment, the following is also set:

[0044] See Figure 8 The outer rosin is connected to the outer end portion of the photointestinal color layer 32, and the outer rosin includes a plurality of positioning blocks 101 fixed to the light-changing color layer 32, and the plurality of connections are adjacent two positioning blocks 101. The magnetic ridge 102 and the magnetic point 103 connected in the middle of the magnetic ridge 102, and the positioning block 101 is opened to each other, and the inner tank is fixed, and the angle of the magnetic ridge 102 is fixed to the inner wall of the inline. Further, the portion of the magnetic ridge 102 is located in the insertion tank is a helical, and the magnetic ridge 102 is located outside the positioning block 101 is a flat straight shape, and the magnetic point 103 is made of a magnetic material, and magnetic point 103 is magnetic. There is a magnetifier force between the block 9, and the magnetic ridge 102 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com