Fingerprint chip spraying method, fingerprint chip manufacturing method, fingerprint chip module manufacturing method and fingerprint chip module manufacturing equipment

A fingerprint chip and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, character and pattern recognition, instruments, etc., can solve problems such as inability to spray chips, and achieve the effect of eliminating manual typesetting, saving labor costs, and improving spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to better understand the above technical solutions, the technical solutions of the embodiments of this specification will be described in detail below through the drawings and specific examples. It should be understood that the embodiments of this specification and the specific features in the embodiments are the technical solutions of the embodiments of this specification. It is a detailed description, rather than a limitation to the technical solutions of this specification. In the case of no conflict, the embodiments of this specification and the technical features in the embodiments can be combined with each other.

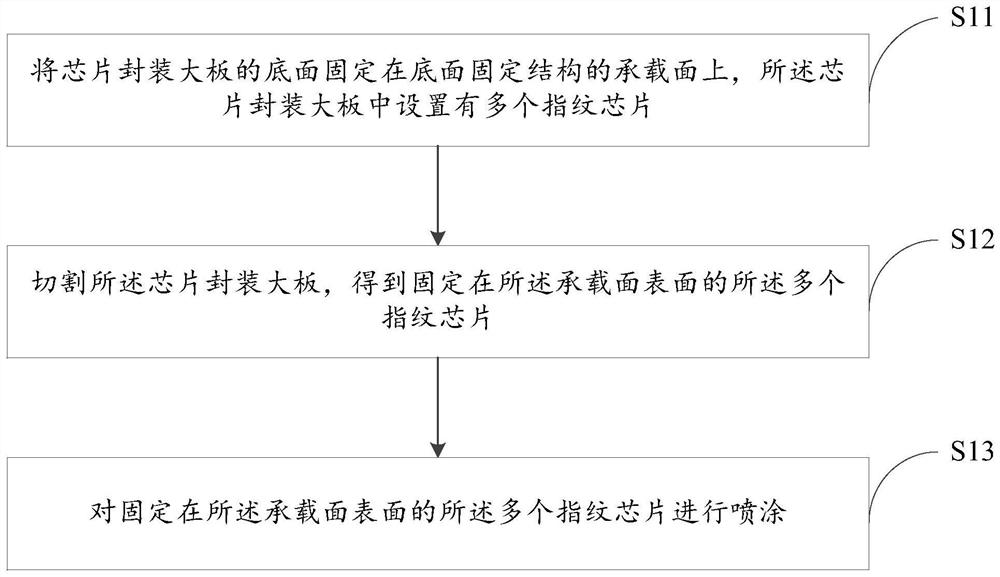

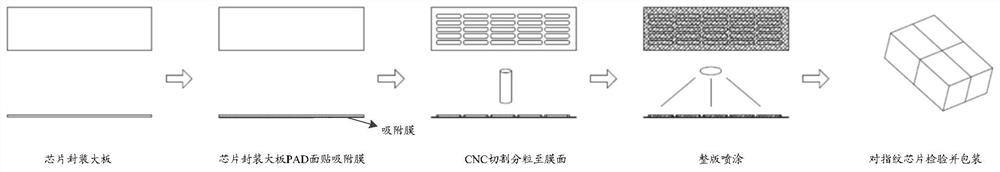

[0048] The embodiment of this specification provides a fingerprint chip spraying method, such as figure 1 As shown, it is a flow chart of a fingerprint chip spraying method provided by the embodiment of this specification. The method includes the following steps:

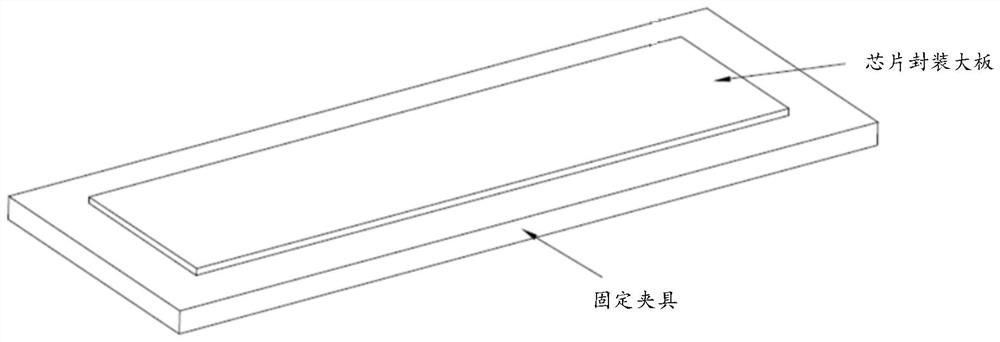

[0049] Step S11: Fixing the bottom surface of the chip packaging large board on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com