Battery replacing truss carrying robot

A technology for handling robots and electric trusses, applied in the field of robots, can solve the problem of no battery replacement device, etc., and achieve the effects of improving the movement ability, facilitating grasping, and increasing the safety detection function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

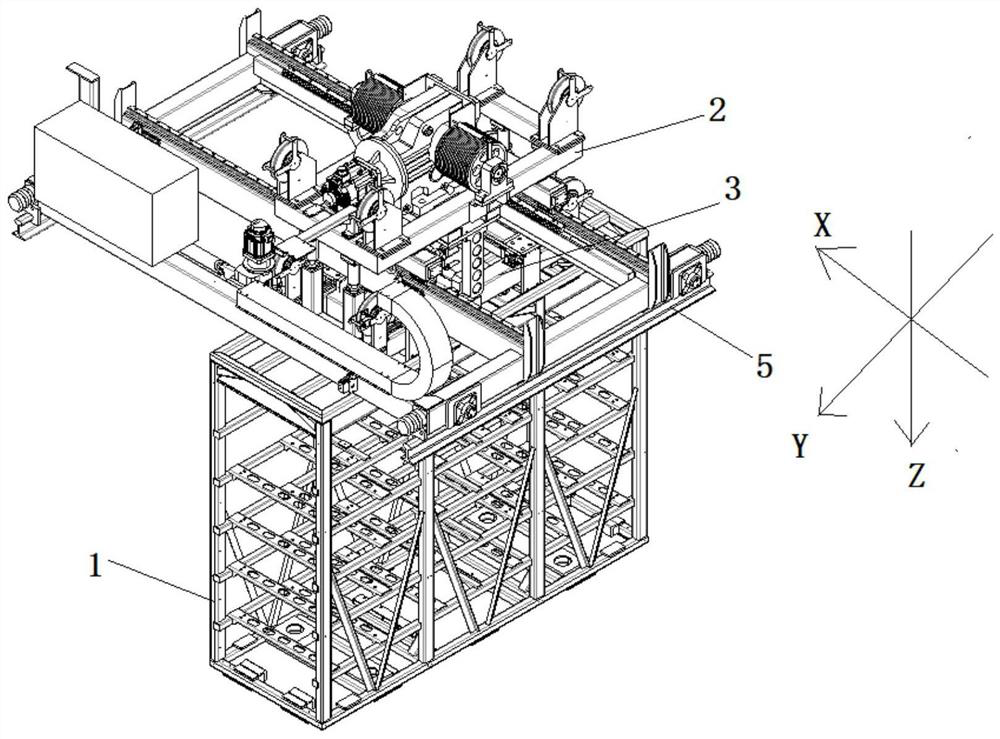

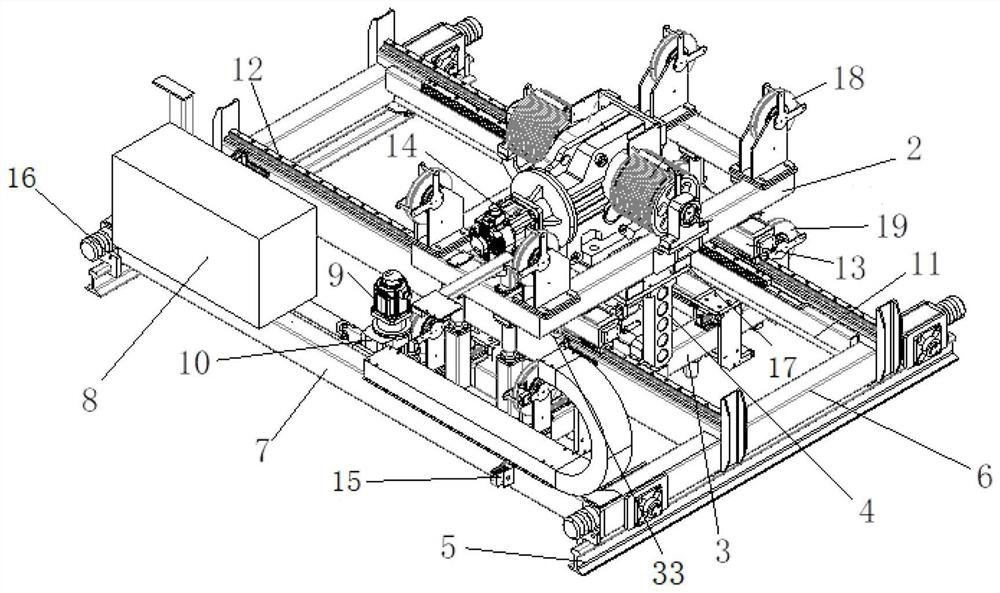

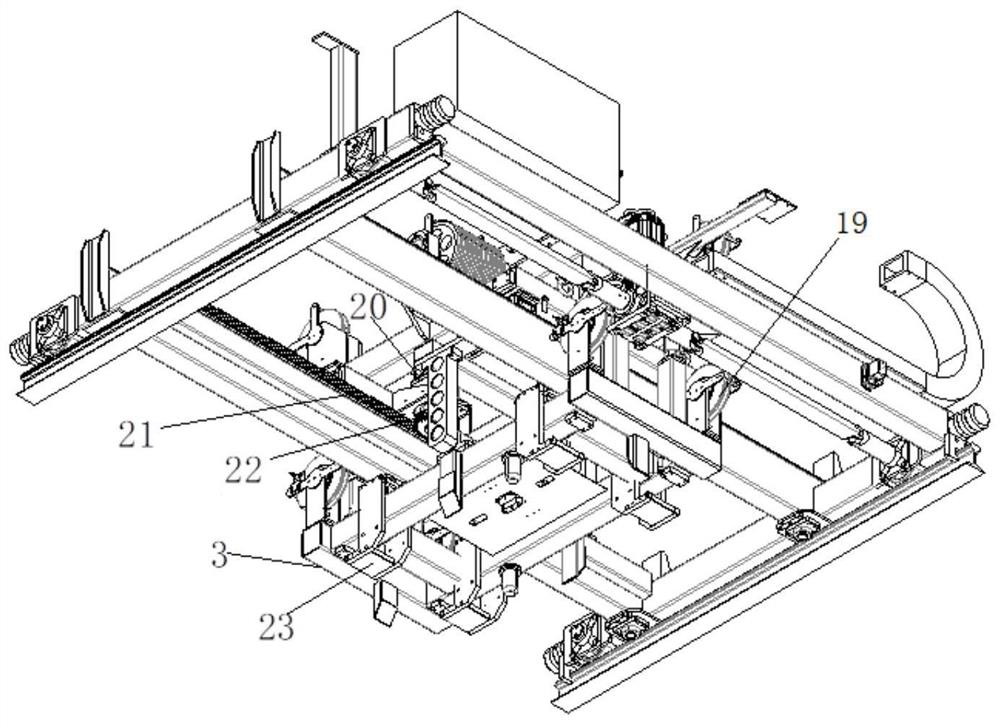

[0032] A power exchange truss handling robot, which works on the upper side of the battery box 1, includes a moving base 2, a grabbing base 3 fixedly connected to the moving base 2, and Y-direction rails 5 arranged at both ends of the moving base 2, wherein the The moving seat 2 includes a Y-axis moving device with the moving seat 2 sliding on the Y-direction rails 5 at both ends, an X-axis moving device that drives the grabbing seat 3 to move in the X direction, and a Z-axis moving device that drives the grabbing seat 3 to move in the Z-axis direction. A shaft moving device, the grabbing seat 3 is provided with a grabbing device for grabbing the battery of a heavy truck.

[0033] In this embodiment, the Y-axis moving device includes two Y-axis moving columns 6 respectively slidably arranged on two Y-direction rails 5, wherein the Y-direction rails 5 are placed on the external ground or base, and only need It can be set according to the width of the two Y-axis moving columns 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com