A graphene hybrid organic-inorganic anti-corrosion coating and preparation method thereof

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, alkali metal silicate coatings, etc., can solve the problems of anti-corrosion coating durability, poor anti-corrosion effect, etc., and achieve significant layer barrier corrosion and good flexibility Sexuality and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

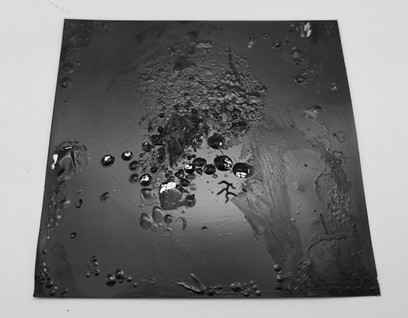

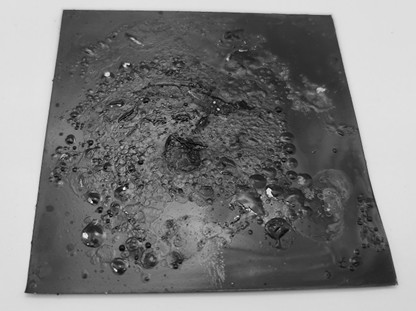

Image

Examples

Embodiment 1

[0033] (1) Preparation of component A: Add sulfonated melamine formaldehyde resin and composite diffusing agent into water for high-speed stirring and dispersion, then add graphene, and use high-speed homogenization to disperse at 19000rpm for 15 minutes to obtain a fine graphene slurry, then add silicon Potassium acid is uniformly dispersed to obtain inorganic dispersion slurry; wherein, the mass ratio of sulfonated melamine formaldehyde resin, composite diffusing agent, graphene, potassium silicate, and water is 1:2:2:4:50; the composite diffusing agent is n-octanol, fatty alcohol polyoxyethylene ether, and dimethyl sulfoxide are compounded according to the mass ratio of 1:1:3;

[0034] Add the organic fluorosilicon polymer emulsion into the inorganic dispersion slurry, stir slowly and evenly, then add water-based epoxy resin, talc powder, acrylic leveling agent, defoamer, stir slowly, adjust the viscosity to 2300cP with water, and obtain A Components; wherein, the mass rati...

Embodiment 2

[0038] (1) Preparation of component A: Add sulfonated melamine formaldehyde resin and composite diffusing agent into water for high-speed stirring and dispersion, then add graphene, and use high-speed homogenization to disperse at 19000rpm for 15 minutes to obtain a fine graphene slurry, then add silicon Potassium acid is uniformly dispersed to obtain inorganic dispersion slurry; wherein, the mass ratio of sulfonated melamine formaldehyde resin, composite diffusing agent, graphene, potassium silicate, and water is 1:3:3:5:100; the composite diffusing agent is n-octanol, fatty alcohol polyoxyethylene ether, and dimethyl sulfoxide are compounded according to the mass ratio of 1:1:3;

[0039] Add the organic fluorosilicon polymer emulsion into the inorganic dispersion slurry, stir slowly and evenly, then add water-based epoxy resin, barium sulfate, acrylic leveling agent, defoamer, stir slowly, adjust the viscosity to 2000cP with water, and obtain A Components; wherein, the mass ...

Embodiment 3

[0043] (1) Preparation of component A: Add sulfonated melamine formaldehyde resin and composite diffusing agent into water for high-speed stirring and dispersion, then add graphene, and use high-speed homogenization to disperse at 19000rpm for 15 minutes to obtain a fine graphene slurry, then add silicon Potassium acid is uniformly dispersed to obtain an inorganic dispersion slurry; wherein, the mass ratio of sulfonated melamine formaldehyde resin, composite diffusing agent, graphene, potassium silicate, and water is 3:5:5:15:100; the composite diffusing agent is n-octanol, fatty alcohol polyoxyethylene ether, and dimethyl sulfoxide are compounded according to the mass ratio of 1:1:3;

[0044] Add the organic fluorosilicon polymer emulsion into the inorganic dispersion slurry, stir slowly and evenly, then add water-based epoxy resin, sericite, acrylic leveling agent, defoamer, stir slowly, adjust the viscosity to 2500cP with water, and obtain A Components; wherein, the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com