Safety fence for maintenance of power transformation box

A technology for safety fences and substations, applied in fences, building types, buildings, etc., can solve the problems of wasting transportation resources and storage resources, save transportation resources and storage resources, reduce the probability of corrosion, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

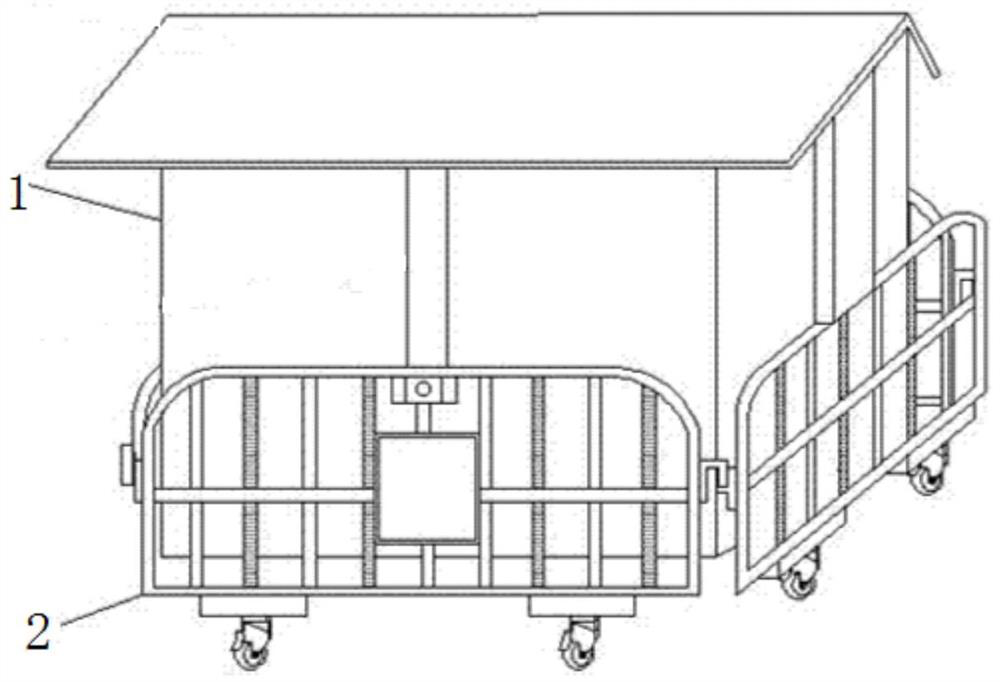

[0050] Such as Figure 2-8 As shown, a safety fence for transformer box maintenance includes a railing 2 .

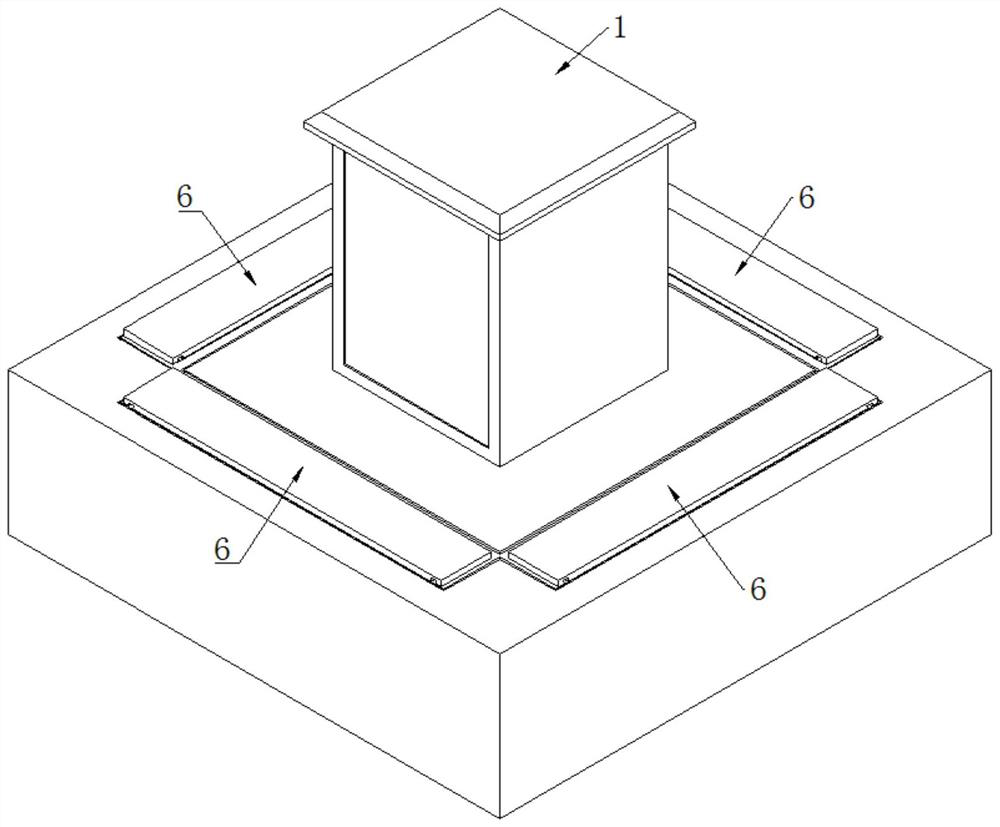

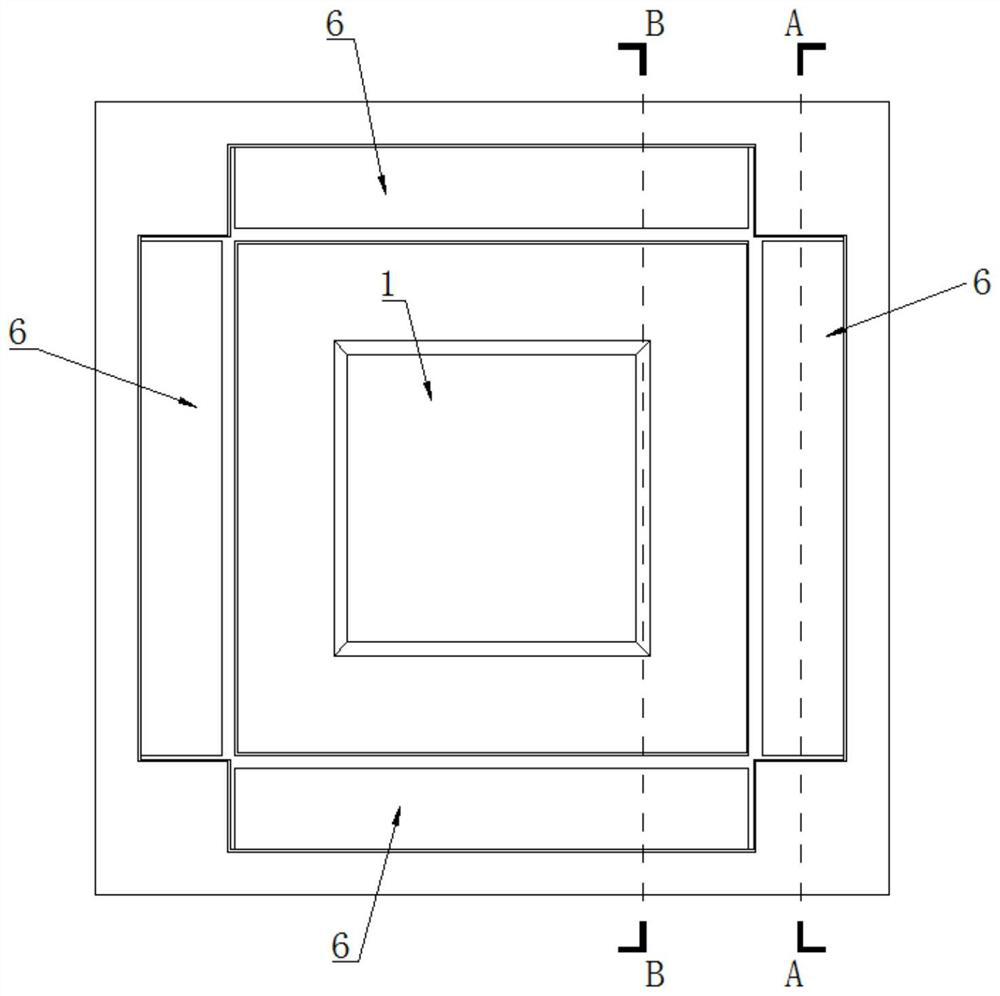

[0051] A reserved pit 3 is arranged in the land around the transformer box 1, and the reserved pit 3 adopts a reinforced concrete pit body structure. The railing 2 is set in the reserved pit 3 . The pit wall of reserved pit 3 is provided with railing guide rail 31, and railing rail 31 is vertically arranged, and railing guide rail 31 is fixed on the pit wall of reserved pit 3 by screw, and railing 2 is provided with railing guide groove 21, and railing guide rail 31 is inserted in railing Inside the guide groove 21. When the railing 2 moves vertically up and down in the reserved pit 3 , the railing guide rail 31 and the railing guide slot 21 move relatively.

[0052] A driving assembly 4 is arranged in the reserved pit 3, and the driving assembly 4 is used to drive the railing 2 so that the railing 2 can move up and down in the reserved pit 3 along the vertical direc...

Embodiment 2

[0064] Such as Figure 9-15 Shown, present embodiment 2 makes further improvement on the basis of embodiment 1:

[0065] In the safety fence for transformer box maintenance in the second embodiment, the opening of the reserved pit 3 is provided with a pit mouth sealing strip 34 , and the pit mouth sealing strip 34 is fixed to the pit mouth of the reserved pit 3 by screws. By arranging the pit mouth sealing strip 34, the rainwater on the ground can be prevented from entering the reserved pit 3 from the gap between the cover plate 6 and the pit mouth of the reserved pit 3, thereby reducing the corrosion of the railing 2 in the reserved pit 3 due to wet rainwater chance, which is beneficial to prolong the service life of the railing 2, thereby saving the cost of replacing and maintaining the railing 2.

[0066] Further, the upper end surface of the cover plate 6 is provided with a mounting groove 62, and turf (not shown in the figure) is laid in the mounting groove 62 . In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com