Multi-coal-seam rock burst prevention and control method for ground drilling pressure relief

A technology for rock bursting and ground drilling, applied in the field of rock bursting in coal mines, can solve the problems of limited cutting height, difficulty in finding a remedial pressure relief method, interruption of coal mining, etc., and achieve the effect of preventing the accumulation of elastic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in more detail below in combination with the accompanying drawings in the embodiments of the present invention.

[0035] A multi-coal seam rock burst prevention and control method for ground drilling pressure relief, comprising the following steps:

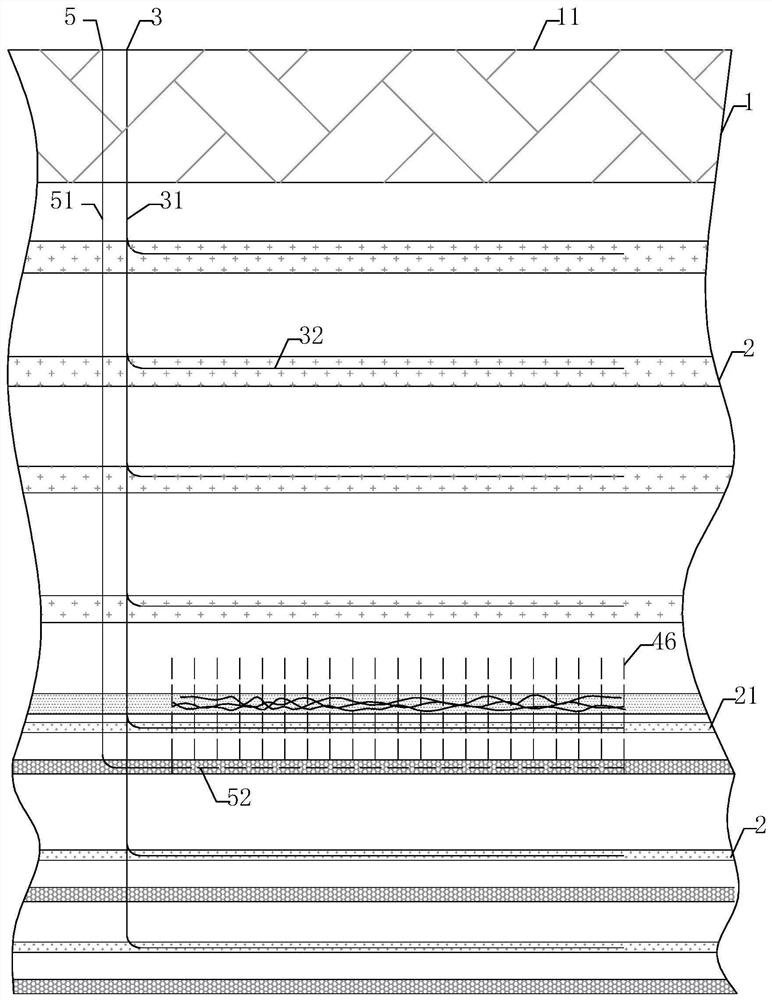

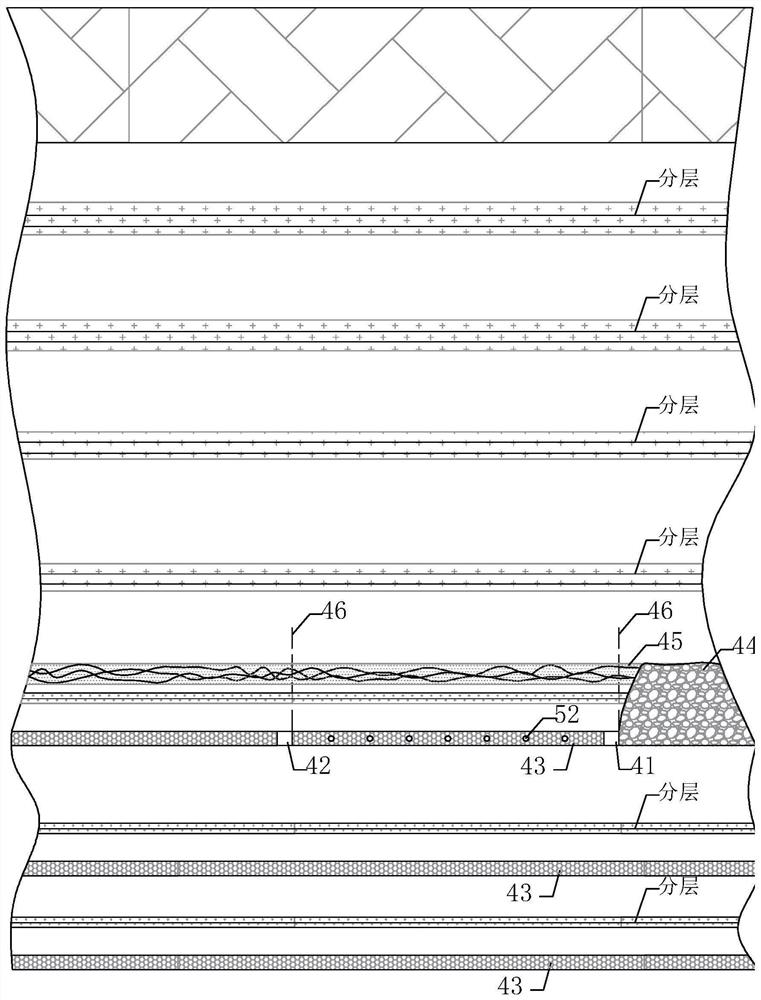

[0036] S1, Construct coal-drawing directional drilling 5 from the ground, the vertical section 51 of the coal-drawing borehole is constructed above the coal pillar of the upper mountain, and multiple coal-drawing drilling horizontal sections 52 are constructed in the uppermost coal seam 43, and advance parallel to the working face The directions are distributed along the dip interval;

[0037] Preferably, the coal-drawing directional borehole 5 is a hole with multiple bottoms, that is, the coal-drawing directional borehole 5 includes a coal-drawing borehole vertical section 51 and a plurality of interval-distributed coal-drawing borehole horizontal sections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com